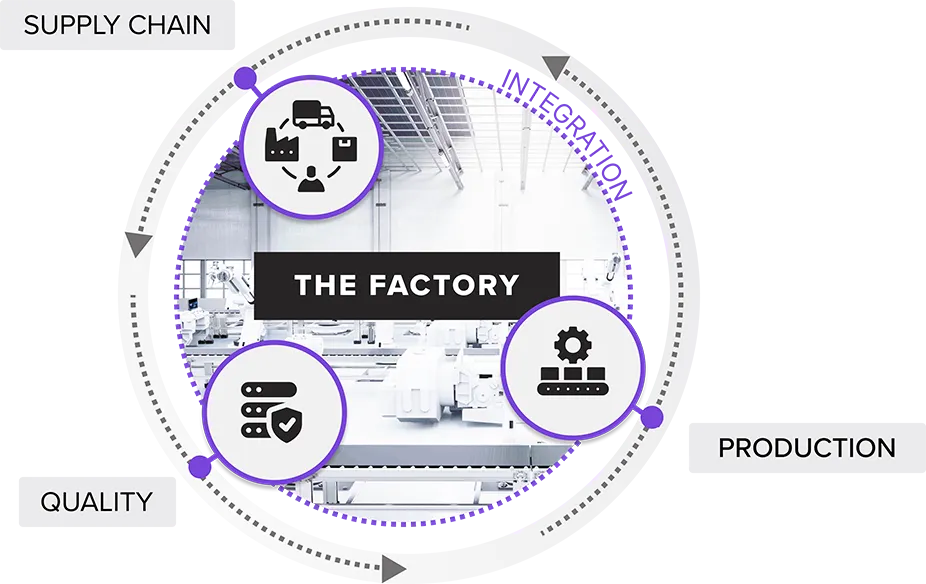

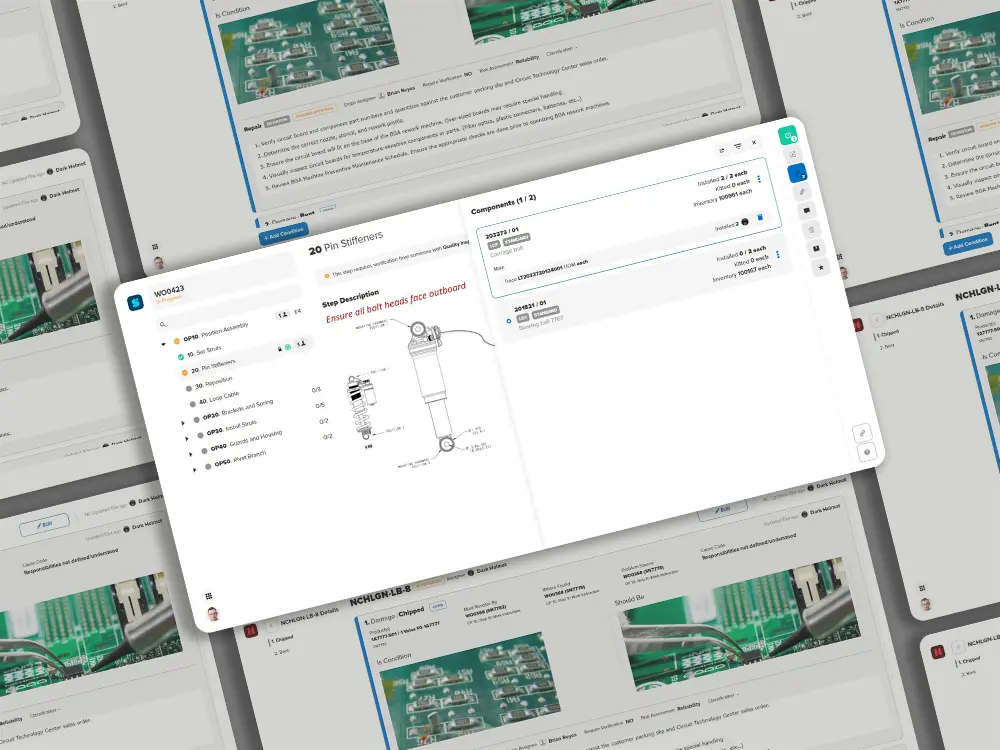

All-in-one integrated solution

Embed Quality

Integrate a quality management solution into your execution system to mitigate risks effectively.

Related built-in applications

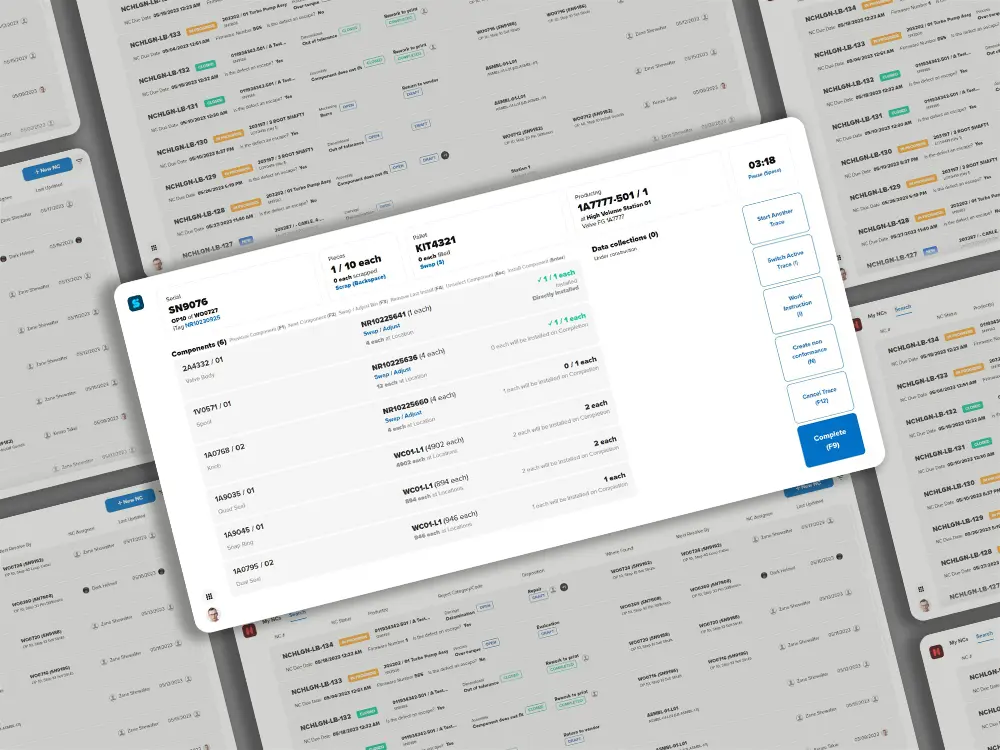

Smart Traceability

Know your As-Built configuration is readily available and accurate. Handle containment quickly.

Related built-in applications

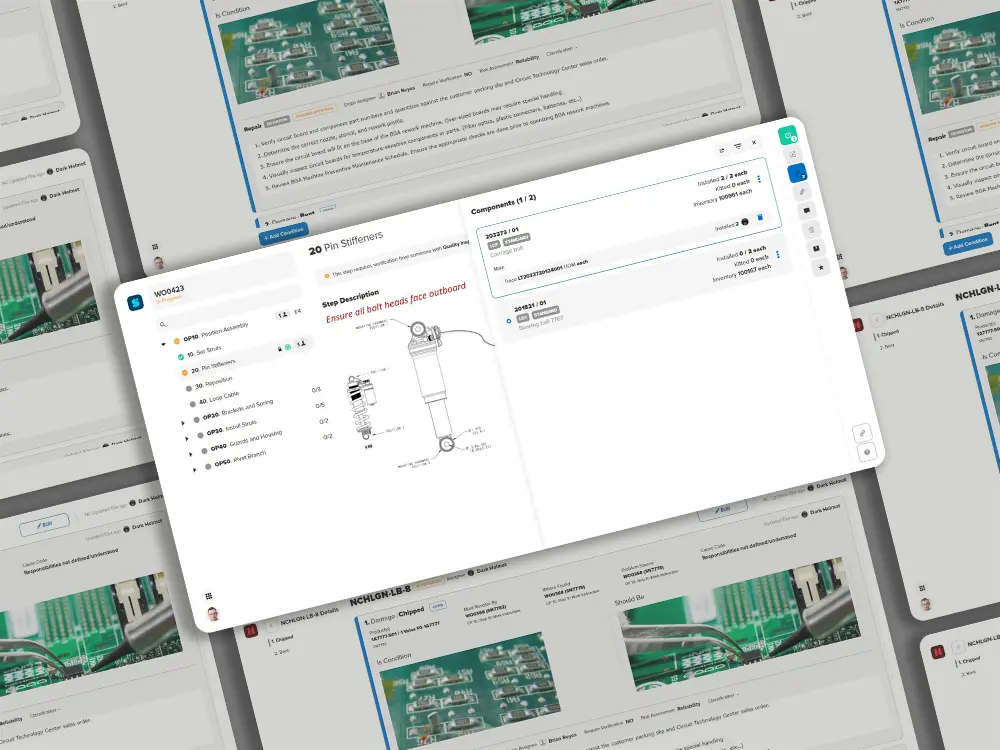

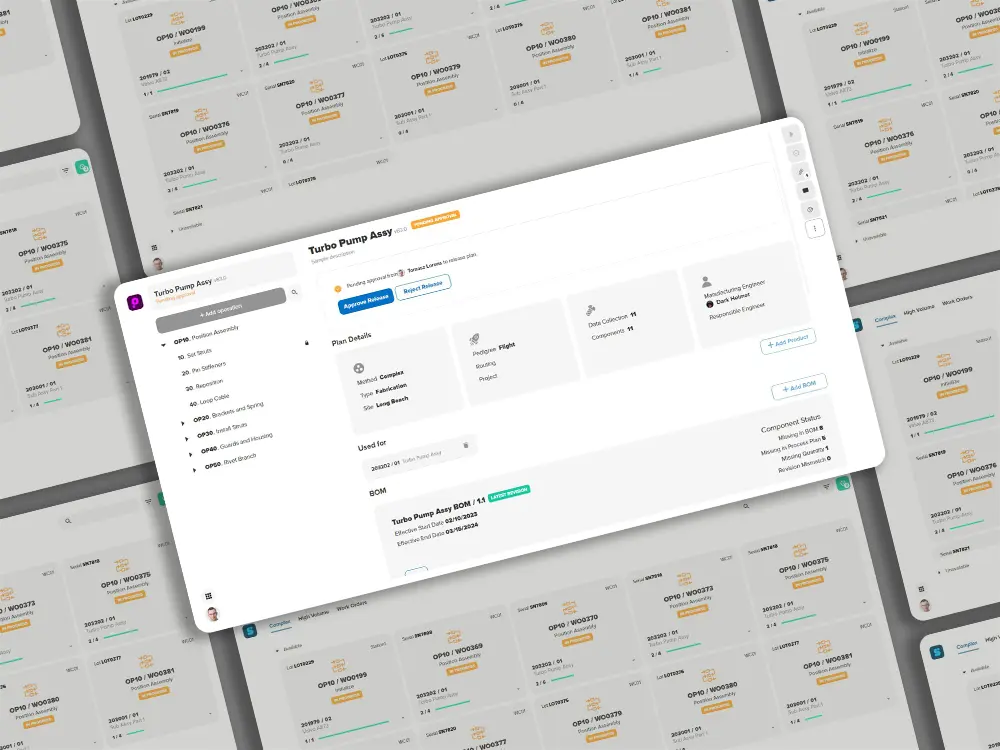

Manage Dynamic Procedures

Manage procedures and operations with precise and adaptable solutions to address both anticipated and unforeseen circumstances.

Related built-in applications

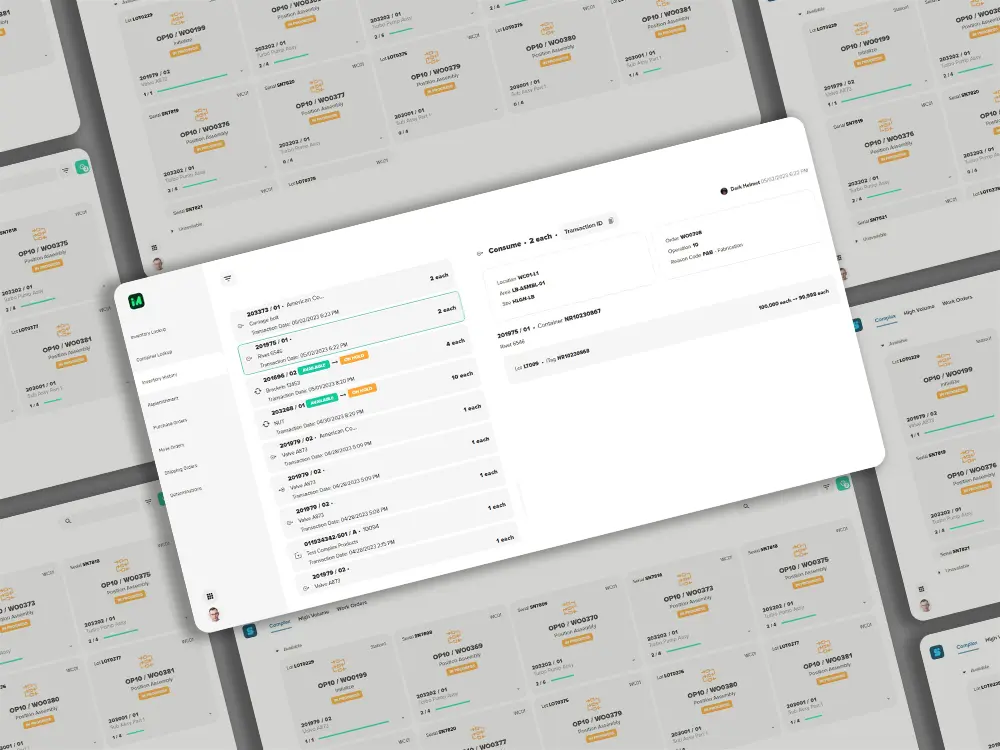

Synchronize Material

From PO receipt, through kitting and delivery, know what you have and where it is needed. Anticipate MRP demand in advance.

Related built-in applications

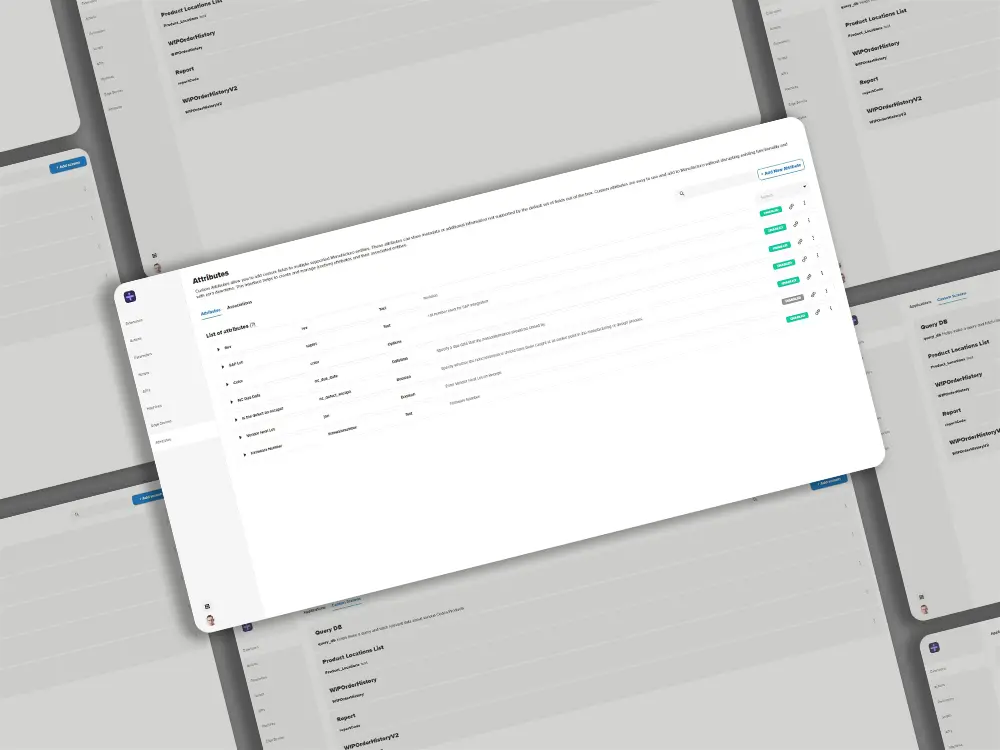

Become Data Driven

When deadlines are tight and resources are limited, accurate live data for decision making is essential.

Related built-in applications

Expedite Integration

On average, our customers achieve phase one go-live implementation within one week to 1 months depending on the scope of integration.

Related built-in applications