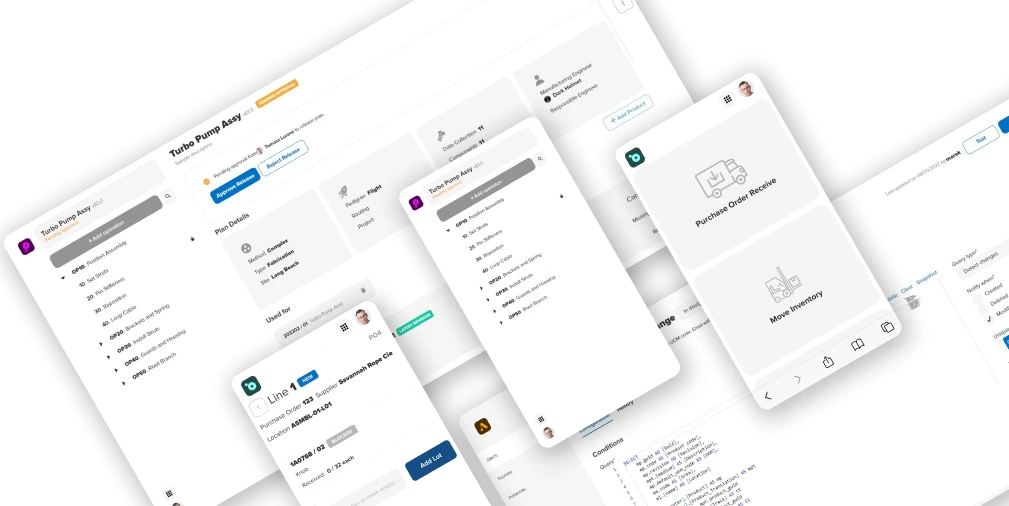

Manufacturo & Relativity Space – One Team, One Vision, One Mission

Manufacturo and Relativity Space share a bold vision—to redefine aerospace manufacturing and push the boundaries of what’s possible. As Relativity scales from single-rocket production to an era of ...