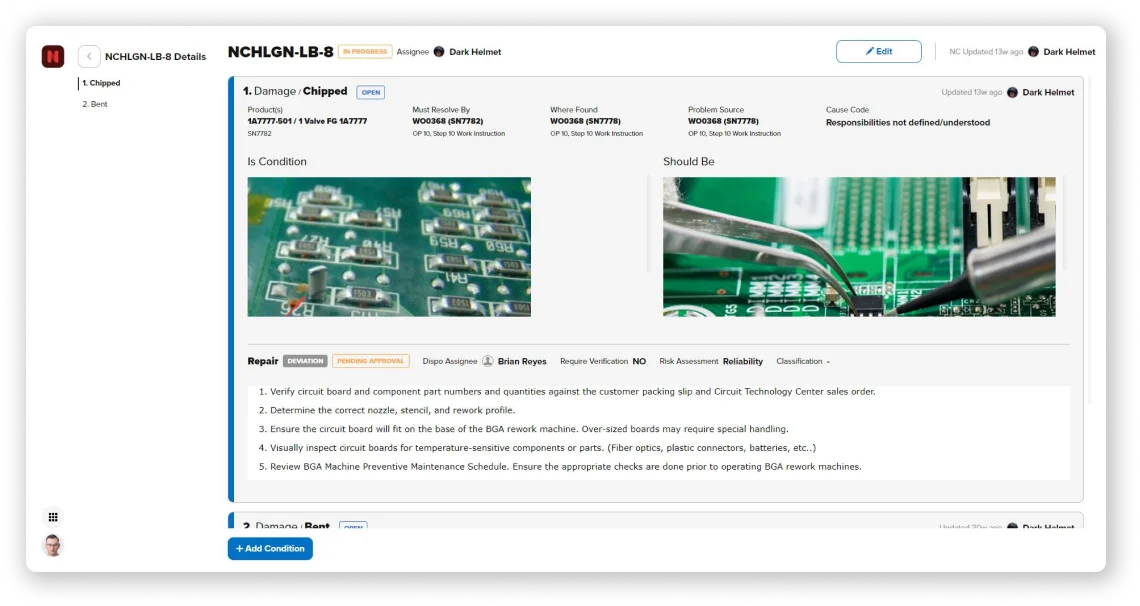

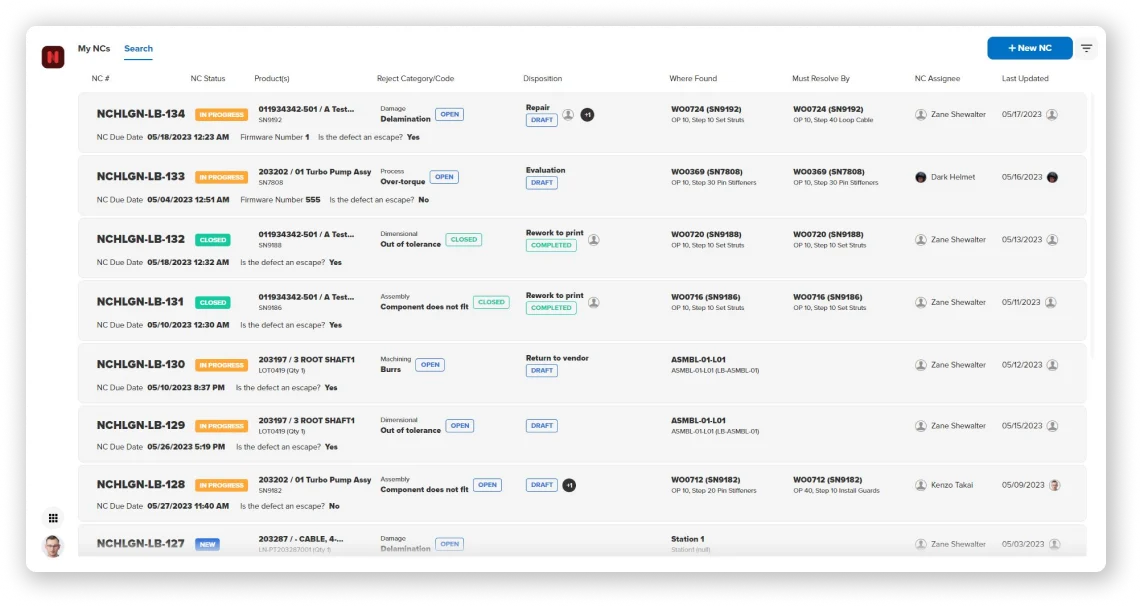

How Manufacturo software manages defects

Some form of consistent and reliable nonconformance management is part of manufacturing operations in most if not all industries. For emerging high-tech manufacturers, effective nonconformance tracking and control is crucial. This approach ensures quality in accordance to ISO9001 or AS9100 standards, satisfies industry and customer demands, and facilitates successful risk management. With Manufacturo Nonconformance Management, you can easily report, track, and actively control defects on the shop floor or in inventory, monitor quality metrics, and drive forward process improvements and quality management best practices.

Manufacturo Nonconformance Management is a next-generation solution seamlessly integrated with production, inventory, one view as-built configuration, and other Manufacturo apps to ensure you can quickly identify, track, and control defects from suppliers, during receipt in the warehouse, or in production on the shop floor.