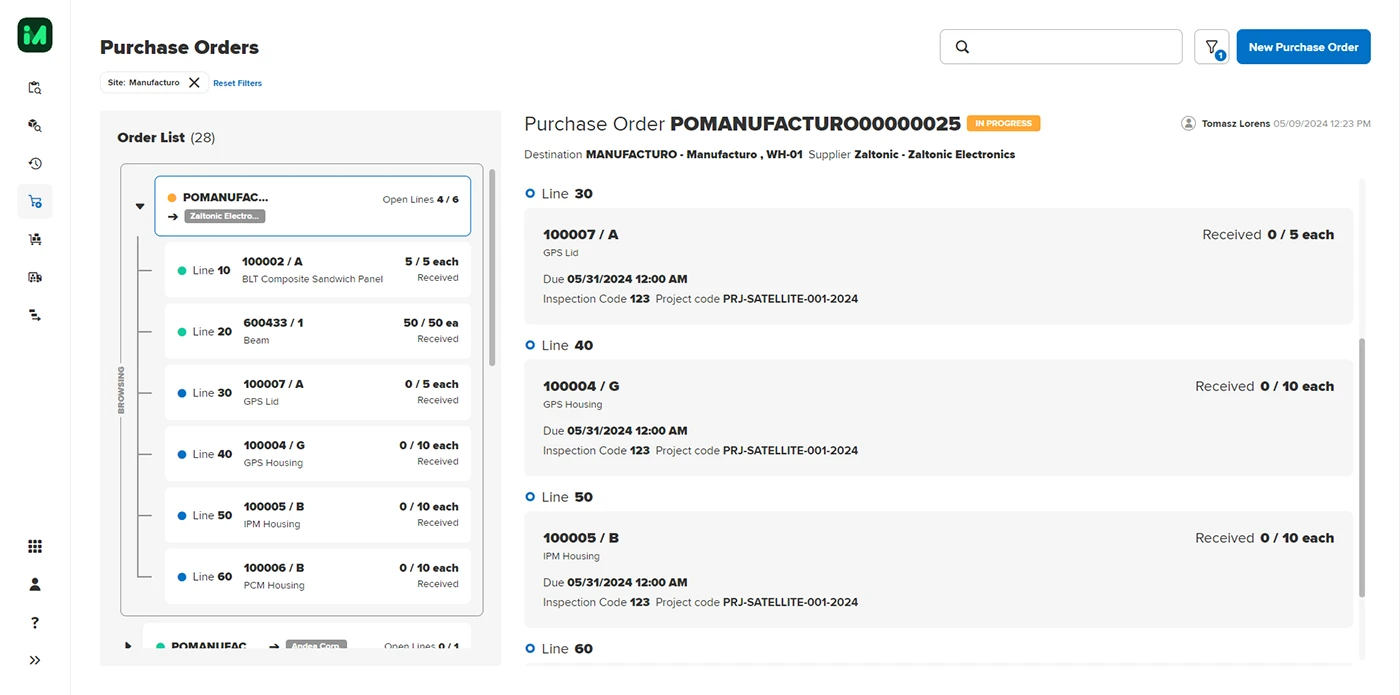

Total control over every part, container, and movement—at every stage.

Inventory connects procurement, production, and fulfillment—but when data is fragmented, it disrupts traceability, delays output, and complicates quality control.

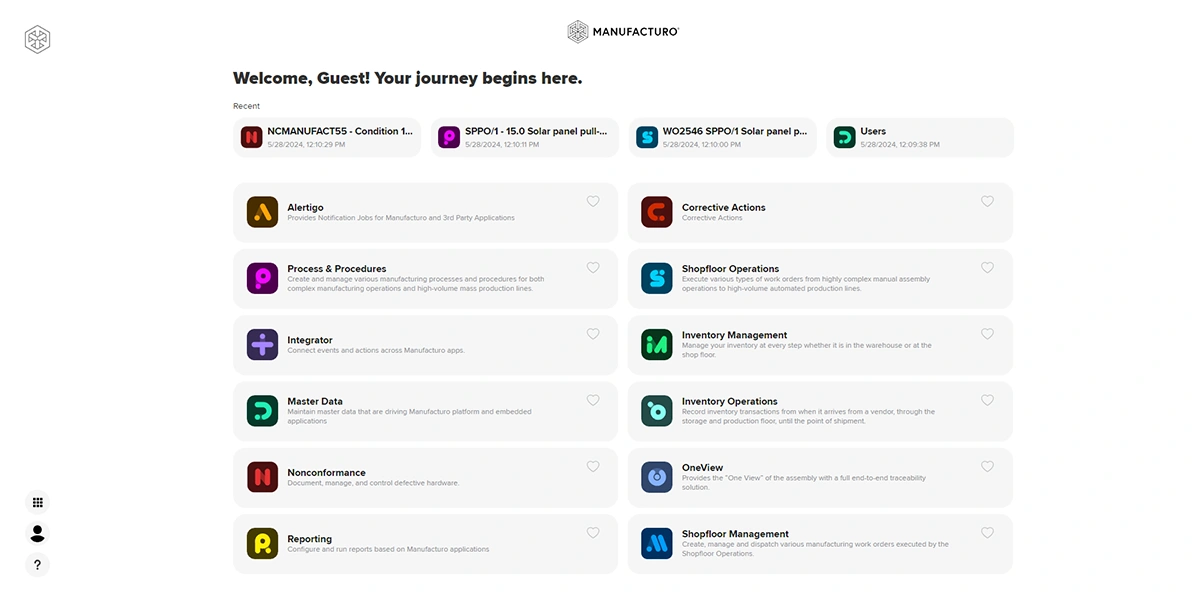

Manufacturo’s Inventory suite solves these problems by providing an end-to-end system of record for all material movement, trace events, and location updates—spanning high-level oversight to hands-on execution.

Our PLM integration with Manufacturo is super seamless and has been incredibly powerful, in terms of the speed tenant...at the beginning of the product lifecycle an engineer can release a part [in PLM] and it's instantaneously pushed to Manufacturo with all its BOM (Bill of Materials) components, as well, which has been another cornerstone of our success here...

Ellen Malloy