MRP Software for Manufacturing: A Comprehensive Guide

Material Requirements Planning (MRP) has undergone a remarkable transformation over recent years, evolving into technologically advanced software transforming standard manufacturing processes.

Material Requirements Planning (MRP) has undergone a remarkable transformation over recent years, evolving into technologically advanced software transforming standard manufacturing processes.

The evolution of MRP Software for Manufacturing over the years, with the infusion of advanced technology and software, is empowering manufacturers to be more flexible, agile, intelligent, and precise in their forecasting and planning. Production schedules and supply chains are enhanced, enabling manufacturers to perfectly balance demand with supply—"threading the needle" between speed and accuracy—to meet demand with total precision.

Material Requirements Planning (MRP) is a supply planning system designed to ensure the timely availability of materials for future production and delivery. It is a smart planning tool that helps manufacturers effectively manage their inventory, production, and procurement processes with a deeper understanding of inventory and material requirements, in addition to customer demand.

The MRP Software for Manufacturing system serves as the central nervous system of the manufacturing operation. Integrating various functions within the manufacturing organization, MRP provides a more cohesive approach to planning, scheduling, and controlling materials and production processes. The end result is complete reliability—fulfilling the production schedule and meeting demand with the right materials available in the right place at the right time.

In the manufacturing industry, MRP can represent two distinct information systems. Both provide the framework to help manufacturing businesses efficiently balance demand and supply, providing production with the inputs to always meet demand.

While the Material Requirements Planning (MRP l) system calculates inputs from the Product Master, Master Schedule, and Bill of Materials (BOM), the Material Resource Planning (MRP ll) system integrates additional business applications such as advanced demand forecasting and features such as real-time inventory and demand forecasting.

Here's another way to think about the difference: Manufacturing Resource Planning (MRP ll) adopts all of the core functionalities from Material Requirements Planning (MRP l) and supercharges it with advanced, intelligent features such as quality control and production planning.

Our MRP system was engineered to provide new competitive advantages to more areas of operation throughout your factory. Discover how speed, accuracy, and intelligence make it possible.

Manufacturing companies can grow and expand in size, scale, and complexity quickly. When this occurs, many manufacturers discover that their Enterprise Resource Planning (ERP) system is not equipped to scale up and adequately support expanded operations. This is the ideal time to consider an upgrade to a modern MRP system, built with advanced tools and technology, to efficiently manage the complexities that come with an increase in pace and depth of production.

The investment to upgrade to a more advanced and comprehensive MRP system should be driven by the operational requirements of your manufacturing business.

This may include the following key indicators:

Production efficiency in manufacturing operations is the great equalizer in today’s ultra-competitive marketplace, fueled by advanced technology and AI-powered automation.

More and more manufacturers are recognizing the critical importance and value of a modern MRP system. To remain competitive, manufacturing businesses need to enhance production to meet demand, while optimizing inventory, managing supply chains, and reducing unnecessary costs and future production slowdowns.

With the arrival of Industry 4.0, it’s become increasingly common to see the integration of IoT devices and sensors, cloud computing and connectivity, and machine learning algorithms and Digital Twins have ignited the proliferation of advanced MRP systems for manufacturing—evolving from a simple planning tool in a conventional (or legacy) system to an essential foundation of smart, future-forward manufacturing business, introducing a new era of agility, and innovation, and precision in the manufacturing field, both large and small, complex and simple.

Implementing a new manufacturing MRP system can be an arduous, complex process. Utilizing proven best practices to guide your process will help streamline and simplify implementation.

Here are the key steps to help you navigate the complexities of implementation and determine the right MRP systems for small manufacturing business requirements:

It's imperative that you dedicate the time and resources to deeply researching the market, to determine which MRP software gives you the tools and technology you will need to realize success and achieve your goals. The first step should be taking a step back, prior to initiating the process, to determine the root cause of your need for a new MRP system, and the pain points it will alleviate.

List the specific features and functionalities you need in an MRP system, such as real-time inventory tracking, automated reordering, or integration with other systems.

Clearly outline what you hope to achieve with the new MRP system.This could include improved inventory control, better production scheduling, or enhanced visibility into the supply chain.

Thoroughly analyze your existing inventory and production management processes. Confirm that MRP has the capacity for requirements. Conduct a thorough gap analysis to gain a deeper understanding of the limitations in the legacy system, which a modern MRP system will address.

Determining the right manufacturing MRP for your manufacturing business should include consideration of who will be using the new system. Common user groups typically include supply chain/production planners, inventory managers, purchasing managers, schedulers, shop floor personnel, technicians, and quality control.

Engage with all key stakeholders, including management, production staff, and IT teams, to solicit input and gain a deeper understanding of each team's unique needs and requirements.

Implementing a new MRP system (and the wealth of integrations involved in significant changes in processes and workflows. Proper change management practices are necessary to ensure that all stakeholders are informed, engaged, and supportive of the migration.

The migration of your data during the MRP system integration process, which spans the boardroom to the shop floor, is essential in streamlining production procedures and ensuring transparency throughout the whole manufacturing process. The successful connection and interaction between MRP software and third-party solutions is crucial.

Before initiating the migration of your data, a thorough QA should be performed. The investment in "cleaning" and standardizing your existing data helps ensure that your system's inventory numbers accurately reflect the on-hand materials in the stockroom.

It's imperative to ensure that all critical data is correctly imported during the transfer stage of the data migration process.

The seamless integration of fragmented legacy MRP systems with your new system requires an interoperable plug-in solution that integrates with third-party systems, manufacturing machines, and tools to increase control and visibility of the entire manufacturing process.

As a subset of supply chain management systems, manufacturing MRP brilliantly balance supply and demand to optimize the manufacturing resource planning process, order management, and inventory control in the following ways:

By providing real-time visibility into inventory levels, MRP systems ensure that manufacturers maintain optimal stock levels. This minimizes excess inventory costs and prevents production delays caused by material shortages.

Visibility into real-time inventory data analytics and the Master Production Schedule (MPS) enable MRP systems to accurately determine the precise quantity of new raw materials required to schedule and run production.

MRP systems for manufacturing facilitate better communication and coordination with suppliers, enabling more timely ordering and delivery of needed raw materials. Smarter, predictive technologies that streamline the process greatly improve the reliability of the supply chain.

Demand forecasting, using predictive analytics: MRP systems utilize historical data and advanced algorithms to accurately predict future raw materials requirements, helping manufacturers accurately align their production schedules with future market and customer demand. This level of precision minimizes inventory levels, and reduces the risk of overproduction, carrying costs, or stockouts.

MRP systems guide optimal scheduling production and manufacturing resource planning throughout the factory, including labor and machinery. Advanced planning and production help reduce costly downtime and boost overall production efficiency in your factory.

Utilizing the Master Production Schedule (MPS), MRP calculates how much time and labor are required to complete each stage in the production process and when each stage needs to be completed, to meet delivery deadlines.

The production schedule details the personnel, machinery, and other resources required to initiate each stage in the production process and order management workflow, automatically generating the appropriate work orders, purchase orders, and transfer orders.

Demand, Master Production Schedule (MPS), Bill of Materials (BOM), and Inventory Requirements

MRP systems rely on accurate and updated inputs, including historical sales, forecasts, and customer orders. The quality of the data available has a direct affect on the effectiveness of the MRP for the manufacturing process.

This plan outlines what products need to be built, and when, while also analyzing customer orders, sales forecasts, and other demand signals.

Each unique product has a detailed list containing the raw materials, components, and sub-assemblies required to manufacture it. It could be a single Bill of Materials, or multiple connected Bill of Materials levels up to a large assembly product.

Using the provided inputs (MPS, BOM, and inventory status records), the manufacturing MRP system can calculate the following:

Material requirements planning helps to determine the precise quantity of raw materials needed to schedule production.

Determine when raw materials should be ordered or produced to schedule production and meet demand.

Calculates the optimal order quantities to minimize costs and avoid excess inventory.

MRP calculates optimal production planning based on real-time visibility into data analytics. The calculations take into account when raw materials and components should arrive, based on when they’re needed in the production process, and when sub-assemblies should be scheduled.

A manufacturing MRP system enables companies to successfully plan, schedule, and execute production efficiently—to deliver finished goods to the customer on time. Optimized inventory management helps ensure that materials are available to be allocated whenever demand requires it, without excessive stockpiling and carrying costs—and preventing stockouts that can delay production.

Success is achievable with a manufacturing MRP system that provides the following features and capabilities:

Ensure all required material requirements are fulfilled for product assembly, when needed

Prevent delays in the production cycle by providing detailed information on components for each sub-assembly and how long it takes to complete each step

Maintain optimal inventory levels with real-time visibility, avoiding the cost of too much inventory

Optimize production scheduling, leveraging a real-time view of on-hand material availability

Identify and address manufacturing issues quickly, improving delivery times

Ensure that the factory runs continuously with minimal slowdowns or delays

Minimize lead times

Streamline workflows

Enhance communication and shop floor control

Simplify complexities

Eliminate manual processes

Create new efficiencies

Ensure delivery of as-built products on time, every time

Enhance customer relationship management and reputation

Complex manufacturers require more complex calculations to build complex products that often require multiple sub-assemblies within the work order. Modern MRP systems provide manufacturers with the tools and technology to manage complex inventory, production, and procurement processes.

Conventional manufacturing MRP systems can be limited in their functionality. Legacy systems are not equipped to handle complexity, can be susceptible to inaccurate data, lack real-time visibility, and cannot adapt to changes in demand. These limitations hinder efficient supply chain management and responsiveness to demand volatility.

Modern MRP systems are designed to efficiently manage production capacity planning for the components that go into each sub-assembly. With real-time visibility into data analytics, Manufacturers have the advantage of valuable insights into the production process and supply chain performance. This insight enables the MRP to accurately anticipate the time required to complete each step in the product lifecycle, boosting manufacturing efficiency, pace of production, and output.

The ability to execute demand forecasting and leverage the resulting purchasing plan for raw materials with precision and optimal cost is imperative to the effective management of production and finished goods inventory.

Accurate production and material requirements planning is even more essential in complex manufacturing, often associated with highly technical product builds, such as aerospace, aviation, or military and defense sectors. A higher standard in material requirements planning for production is a non-negotiable for complex manufacturers, who often have zero room for error in complex manufacturing planning and production.

Industry 4.0 integrates intelligent digital technologies into manufacturing process planning and the production lifecycle, including Artificial Intelligence (AI), IoT networks, Big Data, Digital Twins, and advanced automation.

More intelligent manufacturing processes are increasingly required to remain competiitive and keep pace in a manufacturing business sector witnessing exploding growth of intelligent, AI-powered factories. Manufacturing companies that embrace advanced technology in their modern MRP systems benefit from enhanced productivity, efficiency, agility, and flexibility. Smarter, data-driven decision-making, powered by intelligent manufacturing and supply chain operations, is also a hallmark of enhanced MRP processes and procedures.

The future of MRP software for manufacturing companies is poised for significant advancements due to emerging advanced technologies and evolving industry dynamics.

MRP software designed for manufacturers will be enhanced by a fundamental shift towards cloud-based, flexible solutions--and supercharged by faster, smarter iterations of AI-driven insights and real-time data integration.

These advancements will allow manufacturers to operate with greater agility, efficiency, and sustainability, transforming the way materials and production resources are managed over the next decade.

In the next 5-10 years, the way manufacturers use (and benefit from) MRP software will evolve by leaps and bounds, thanks to technological advancements in the following areas:

IoT (Internet of Things): With the proliferation of IoT devices in manufacturing, MRP systems will pull data directly from machinery, sensors, and production lines to monitor material usage in real-time. This integration will lead to improved accuracy in planning, minimizing waste, and reducing downtime.

Modern MRP systems have matured and evolved rapidly in recent years to become critical tools for manufacturing businesses that want to remain competitive and responsive in today's fast-paced, ultra-competitive market environment.

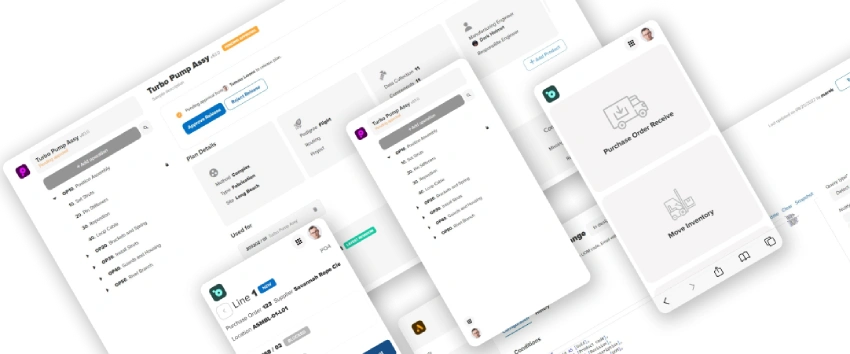

Manufacturo's MRP is a comprehensive, intelligent planning system that helps ensure the right materials are available in the right quantities for allocation at the right time to meet production demands.

Meticulously designed to help manufacturers efficiently manage inventory and production scheduling, removing complexities and simplifying workflows by seamlessly bridging the gap between design, demand generation, supply allocation, and reporting steps.

Here’s a preview of some of the features and benefits that Manufacturo's new MRP system offers, bringing a new level of precision to your manufacturing business:

Improved inventory management

Enhanced production planning

Better resource utilization

Reduced lead times

Cost savings

Accurate demand forecasting

Strengthened quality control and compliance

Scalability and change management

Data-driven decision-making

Now that you've learned about the basics of MRP and its tremendous value to the manufacturing industry, you can evaluate if now is the right time to upgrade to a comprehensive, intelligent system.

Manufacturo's MRP helps ensure that the right materials are available in the right quantities for allocation at the right time to meet production demands.

If this level of precision in your manufacturing business sounds enticing, you can learn more by visiting the new MRP application page on the Manufacturo website.

You can schedule an in-depth product demo with one of our experienced MRP product experts today.