Shopfloor Operations

Smarter Execution. Connected Production.

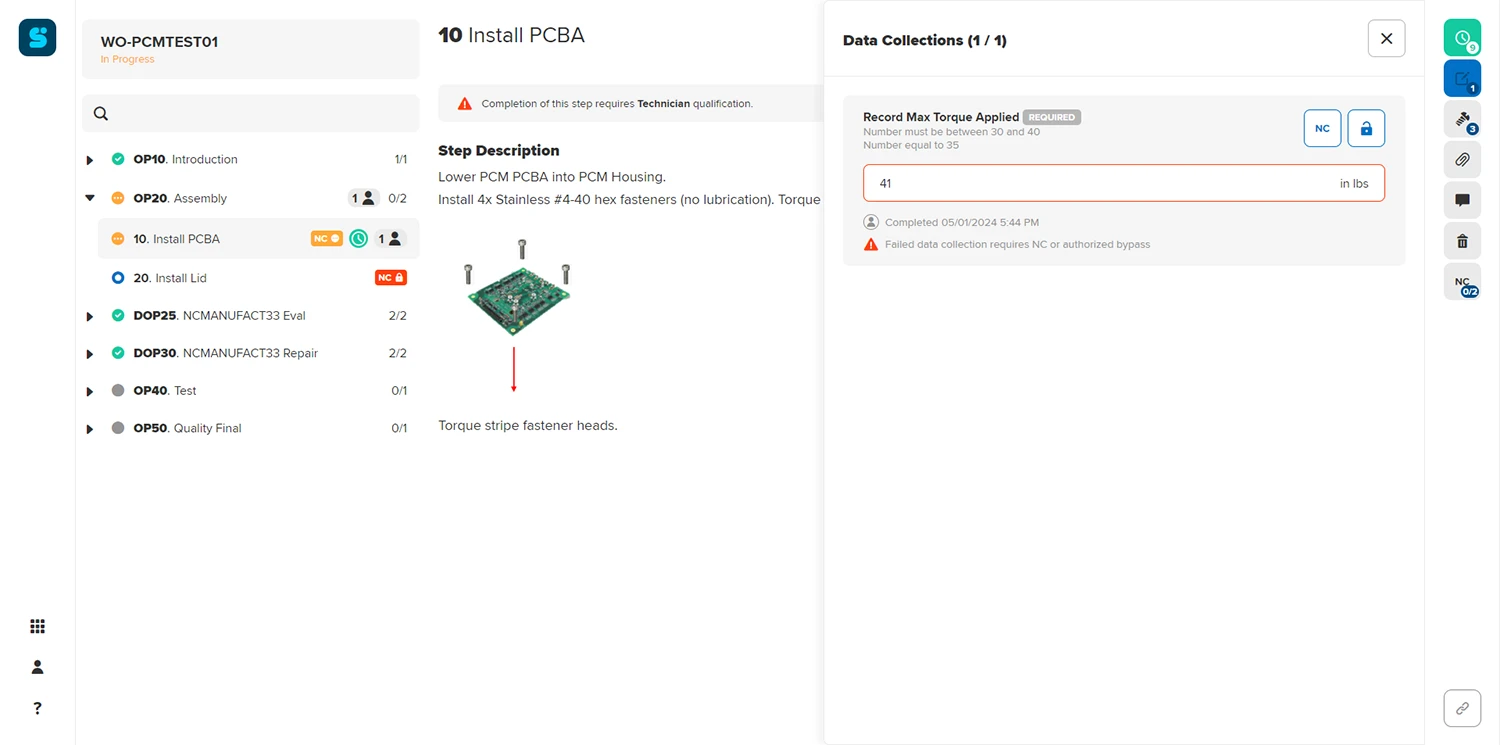

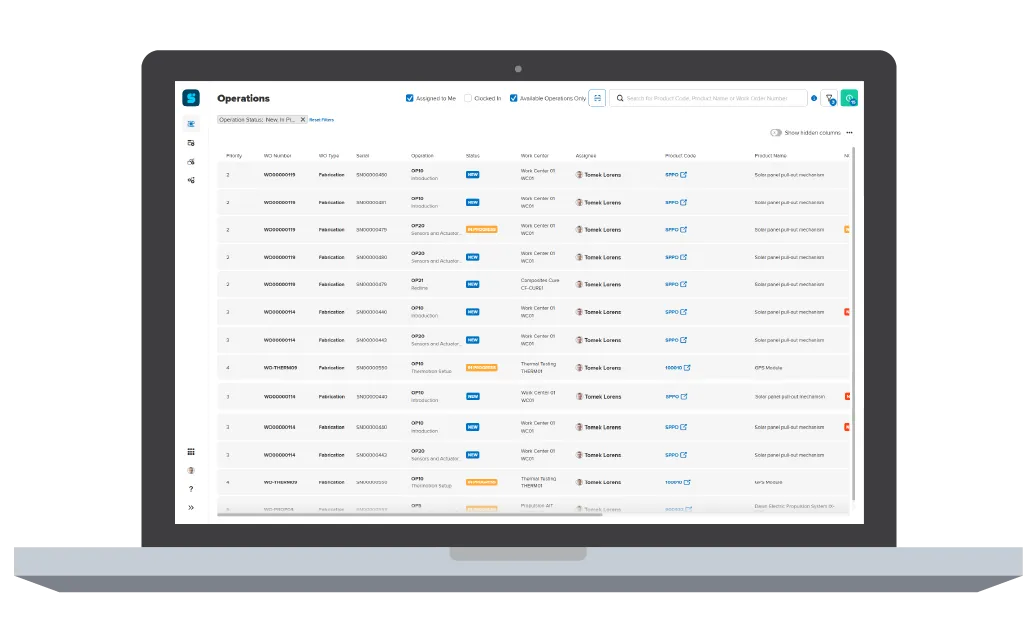

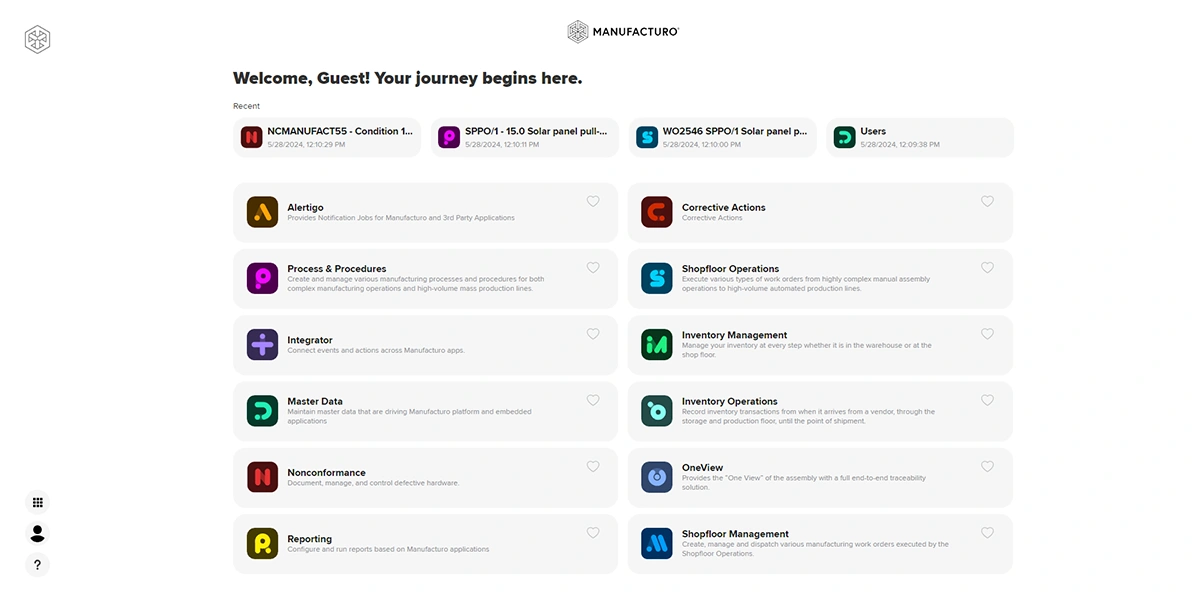

From build to inspection, the Shopfloor Operations App empowers your teams with everything they need to execute work orders efficiently and accurately—fully integrated with quality management, inventory, traceability, and planning. Every action is documented, every step is auditable, and every part is accounted for.

Manufacturo brings all your shop floor activities into a centralized digital workspace—eliminating paperwork, reducing delays, and enabling a more responsive, quality-driven manufacturing process.

Going paperless on the shopfloor is a huge advantage. Having everything digital, you can attach almost any kind of control function to summarize it…So I have 100% traceability of who was working on which workstation, building what assembly under what temperature, condition, and humidity. So, it’s amazing. You can see everything and just with a click, you can combine these lines.

Peter Dachs