Production

Production management encompasses the procedures that determine how complex products can efficiently flow through the assembly, integration, and testing lifecycle, while also syncing with design. The data collection engine captures critical product information available for near real-time analysis, facilitating well-informed decision making and more profitable outcomes.

Quality

Embedded quality management—featuring improved QA processes--yields precision operations that feature greater efficiency and cost savings, strengthened compliance and risk mitigation, and enhanced brand reputation.

Supply chain

Supply chain management (SCM) software establishes the foundation for a steady and reliable flow of high-quality materials and components, from procurement to product delivery.

Manufacturo features

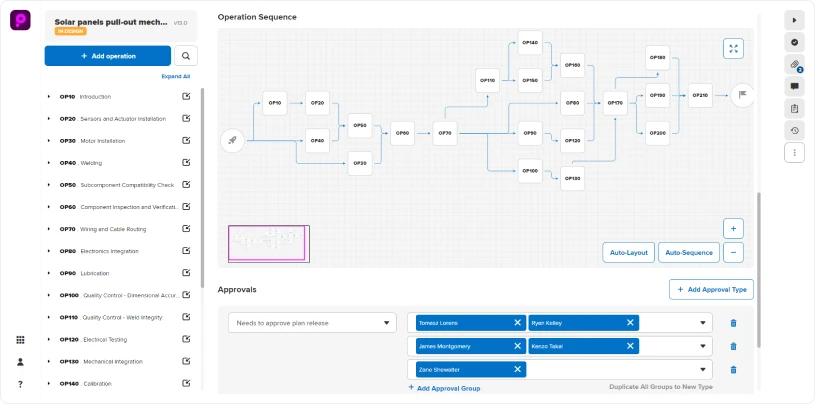

Procedure control

Procedure control is essential for maintaining operational consistency and plays a crucial role in complex manufacturing by providing structured guidelines, clear instructions, and detailed protocols for carrying out various steps, tasks, and processes. Procedure control ensures standardized methods, a unified approach, compliance with regulations, and streamlined operations. Effective procedure control enhances efficiency, reduces errors, manages risks, facilitates training, and drives continuous improvement.

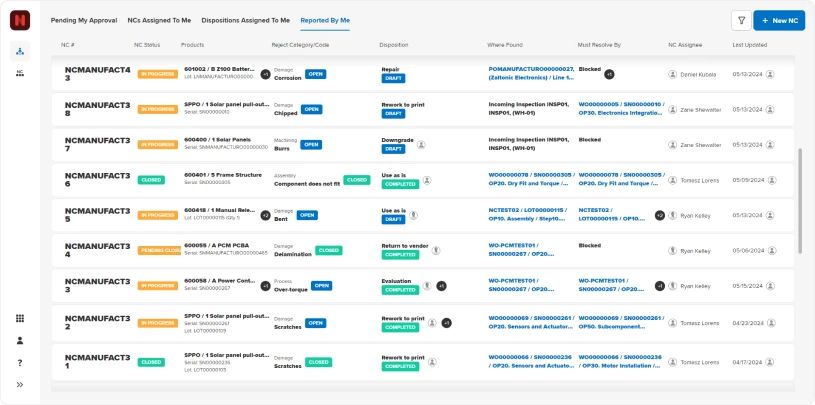

Quality Management System

A Quality Management System (QMS) is a structured framework designed to ensure that products consistently meet industry requirements and regulatory standards. It involves planning, control, assurance, documentation, supplier management, and continuous improvement. A QMS encompasses the entire product lifecycle, from design and development through production and distribution, to customer service. Implementing a QMS helps improve product quality, reduce costs, enhance customer satisfaction, and ensure regulatory compliance.

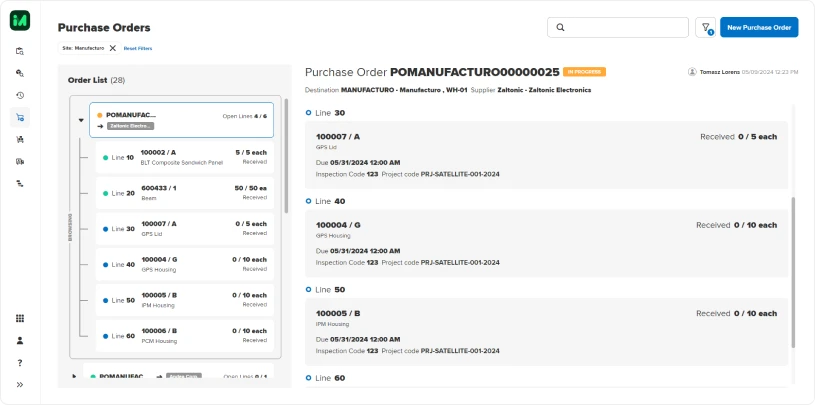

Managed inventory

Effectively managed inventory ensures that materials are available when needed, preventing production disruptions and maintaining operational efficiency. Proper inventory management also optimizes costs by balancing inventory levels, reducing holding costs, and preventing production delays. It also enhances quality control by ensuring that materials and components meet the required safety standards before use. Additionally, well-managed inventory bolsters supply chain resilience by providing buffer stock against disruptions.

Additional features

Data-driven production

Data-driven production involves using data analytics to optimize production processes, predict maintenance needs, improve quality, and enhance resource efficiency. By analyzing data collected in different places and coming from various sources, it is easier to identify and eliminate inefficiencies, prevent equipment failures, reduce waste, and adapt quickly to changing production requirements. The data-driven approach to manufacturing enables informed decision-making, improves operational performance, and ensures quality that complies with industry standards, regulations, and norms.

Integration

Data integration, spanning from the boardroom to the shop floor, is essential in streamlining production procedures and ensuring transparency throughout the whole manufacturing process. Particularly in complex industries with high production costs and rigorous safety regulations, the successful interaction between manufacturing software and third-party solutions is crucial. The integration of MES systems, ERP software, PLM solutions, supplier portals, and accounting software transcends beyond technological decisions, emerging as a strategic imperative.

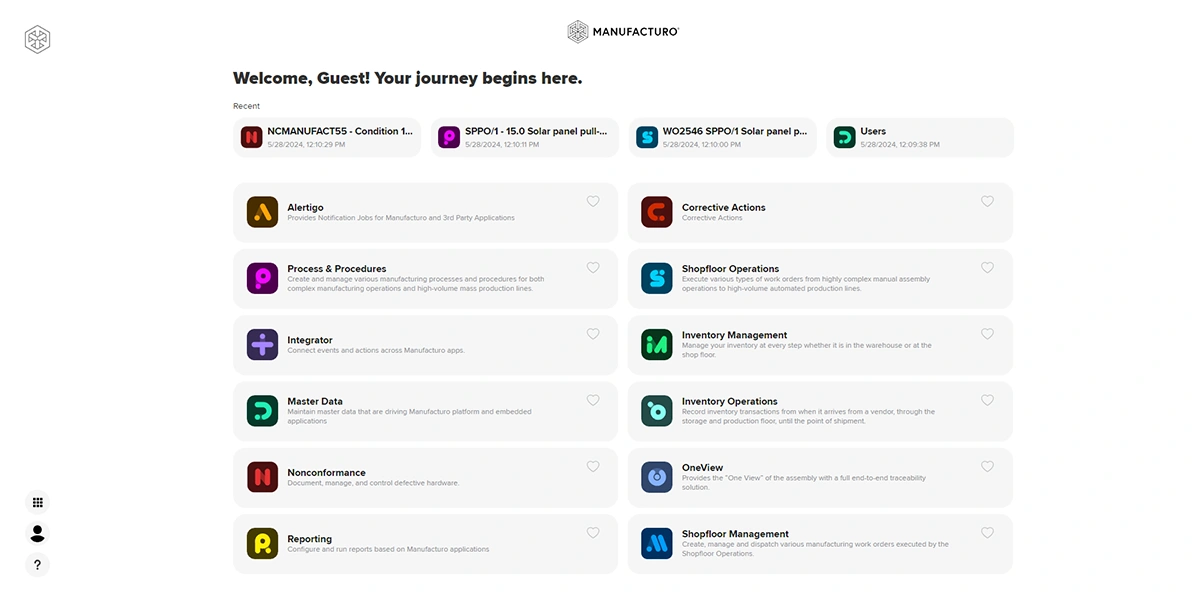

Manufacturing management software for your quality, production, and supply chain needs

Control all key manufacturing areas with Manufacturo’s all-in-one integrated solutionManufacturo differentiators

Molds into your manufacturing model, not the other way around

Highly flexible and easily configurable to meet your specific requirements

Designed by experts with years of hands-on experience in complex manufacturing

Extensive out-of-the-box features to make you go live within a few weeks or even sooner

See what our Customers are saying on G2

We're proud to be featured on G2, a trusted platform for software reviews. Check out our profile to see what our customers have to say about their experiences with us. Your feedback helps us improve and serve you better every day.