Eliminate Uncertainty, Drive Accountability with Action Boards

Integrated, Transparent, and Data-Driven Action Tracking for the Shop Floor

In fast-moving manufacturing environments, timing and accountability can make or break productivity. One delayed inspection or missed handoff can cascade into hours of lost efficiency. Most systems treat shop floor issues as isolated events—disconnected from the people, processes, and context needed to solve them.

Action Boards changes that

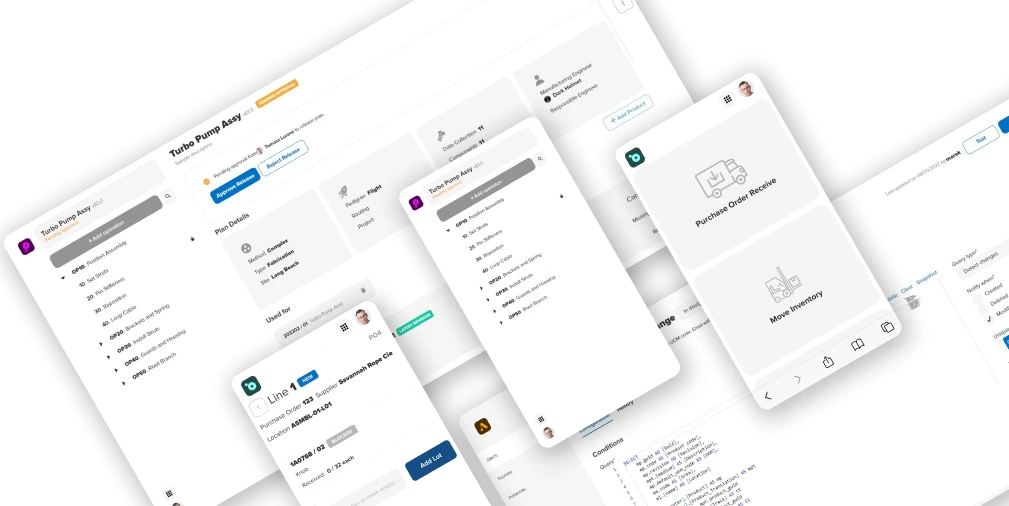

Purpose-built for high-complexity, high-mix manufacturing, Action Boards transforms how teams coordinate, respond, and resolve essential tasks. It replaces the guesswork with real-time visibility and ensures the right people are aligned at the right time—so issues don’t just get flagged, they get fixed.

Action Boards is the ultimate accountability and action-tracking system. Fully integrated into the Manufacturo manufacturing management system, Action Boards ensure that every action is assigned, monitored, and resolved efficiently. No more lost requests, no more uncertainty—just complete transparency and accountability at every step.

Action Boards represent the first step in Manufacturo’s unified and extensible Actions Framework—a powerful platform for managing essential tasks across the full spectrum of manufacturing operations. More than a digital callboard, Action Boards empower teams to streamline safety reporting, nonconformance mitigation, facilities dispatching, feedback loops, and even engineering change processes—all while leveraging the same intelligent engine behind our Nonconformance workflows.

When Timing Is Everything

In complex manufacturing environments, the cost of inaction is high. Technicians often wait on inspectors or engineers with no visibility into when help is coming—or whether anyone even received the call. Traditional systems aren’t built to handle the dynamic flow of shop floor requests, resulting in missed actions, delayed inspections, and mounting frustration.

Studies show that as many as 70% of action calls are rejected because technicians are not ready. Manufacturo’s Action Boards solve this by aligning readiness between technicians, inspectors, and engineers—ensuring requests are made and received at the right time, by the right people. This prevents wasted effort and accelerates resolution across the floor.

Action Boards Features That Ensure Accountability

Transparent Issue Resolution

- Every call or action is tied to a specific constraint or follow-up, creating a traceable path from request to resolution.

- Clear task ownership from initiation to completion.

- Enhanced clarity through action types, sub-actions, and resolution status codes (e.g., completed, partially completed, rejected).

- Real-time updates on process time, assignee, and status in an intuitive, user-friendly interface.

- Enables resolution of low-complexity, non-systemic issues (such as NC Further Actions) without requiring formal CAPA initiation.

- Addresses material defects, design discrepancies, and training-based process issues.

Actionable Insights & Reporting

- Tracks action volume, rejection rates, resolution times, and team responsiveness.

- Offers visibility into technician call frequency and wait times, helping managers eliminate delays and reduce inefficiencies.

- Prevents duplicate or redundant calls by consolidating requests in one centralized system.

- Provides meaningful insight into performance—who’s waiting, who’s responding, and where to focus support.

Provides Support Where Needed

- Assigns actions to specific roles to ensure task execution by qualified personnel.

- Synchronizes availability of technicians, inspectors, and engineers to reduce delays.

- Strengthens team collaboration by providing shared visibility and real-time updates.

- Drives higher reliability by removing guesswork from dispatch and response workflows.

Built-in Workflow Expansion & Customization

- Flexible like a ticketing system but built natively for manufacturing environments.

- Supports an expanding range of high-impact workflows: safety, facilities, maintenance, feedback, further actions, engineering changes, and more.

- Uses effectivity-driven controls to constrain actions within authorized procedures.

- Natively integrated with Manufacturo documents, procedures, quality systems, and production execution tools.

- Provides a consistent and scalable structure that evolves with operational complexity.

Super Charge Your Accountability & Productivity

Take a virtual tour to see our software in action

The Productivity Payoffs of Action Boards

With Manufacturo’s Action Board, accountability isn’t just a concept—it’s an operational standard.

Built with love for the shop floor, not retrofitted from IT systems, Action Boards are the foundation of a smarter, more connected manufacturing future. Every action is assigned, tracked, and resolved—so your teams can focus on what matters most.

Eliminates Workflow Obstacles

Ensures timely response and resolution of all tasks.

Creates Full Transparency

Provides a clear, real-time view of every action, assignment, and resolution status.

Improves Collaboration

Seamlessly connects shop floor teams, engineers, and quality inspectors in one unified system.

Reduces Lost Actions

Eliminates reliance on temporary communication channels by keeping records structured and trackable.

Optimizes Workflows

Monitors waiting times, call frequency, and prevents duplicate action calls for maximum efficiency.

Reduces Tech Stack

Eliminates reliance on other management platforms or communication channels.

Learn How Action Boards Can Improve Your Production Process

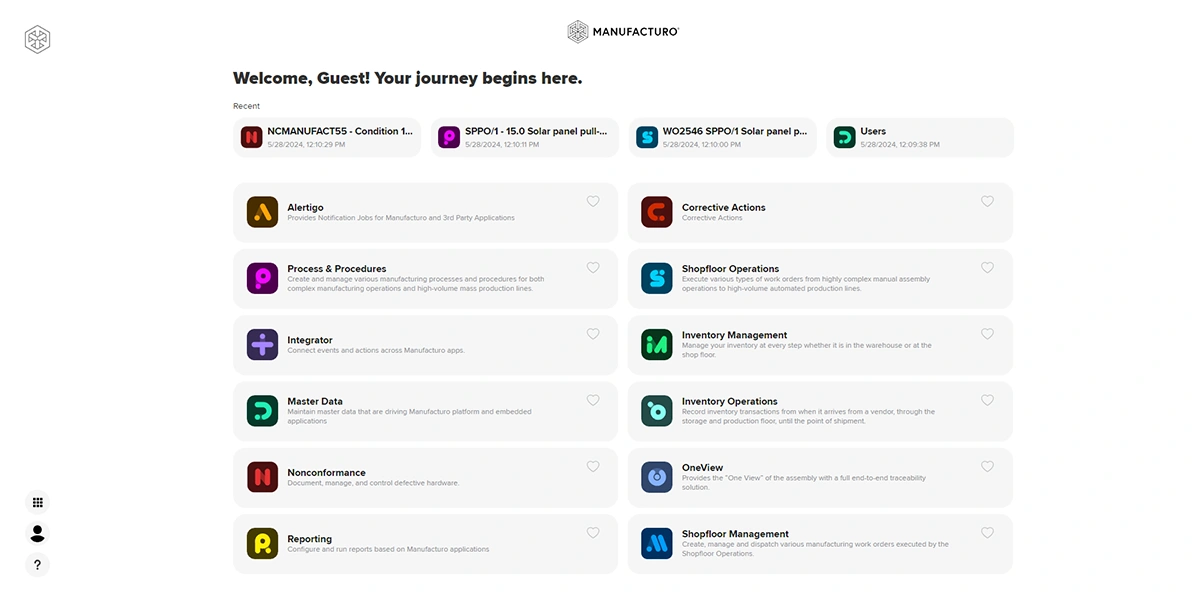

Check out our other applications

Seamlessly drive your production across all manufacturing models

Streamline your production processes and cut manufacturing costs

Monitor equipment availability, status, maintenance and calibration dates to eliminate inefficiencies

Ensure the right materials are available to meet production demands.

Control all inventory movements and contain defects at every step

Transforms pull-based replenishment into a connected, responsive system.

Eliminate nonconformance issues, mitigate nonconformity risk, and increase regulatory compliance

Effectively manage corrective, preventive, and containment actions and configure custom action types to improve your entire CAPA process

Centralize and control all documents within Manufacturo

Gain enhanced traceability to increase safety and compliance

Gain holistic visibility to predict, identify, and eliminate potential issues before they become critical blockers

Embed screens and customize attributes to improve data accuracy, streamline workflows, and increase productivity