Drive action with targeted alerts

ALERTIGO, Manufacturo’s alerts and notifications app, empowers manufacturers to stay ahead of issues without being overwhelmed by irrelevant notifications. By monitoring system data and triggering targeted alerts, ALERTIGO helps teams act on the right information at the right time, ensuring critical updates don’t slip through the cracks.

Whether you’re managing a high-complexity build, maintaining calibration schedules, or overseeing production quality, ALERTIGO keeps your teams focused, informed, and ready to act.

Why manufacturers need smart alerting

Standard monitoring tools often fall short in highly regulated, fast-moving manufacturing environments. Teams either drown in irrelevant notifications or miss critical updates that impact delivery timelines, quality, or compliance.

Manufacturers need:

- Early warning signals before issues escalate.

- Targeted alerts that reach the right people through the right channels.

- Automated, reliable notifications integrated into daily operations.

ALERTIGO addresses these needs while running quietly in the background, giving your teams the confidence that they will be informed when it matters most.

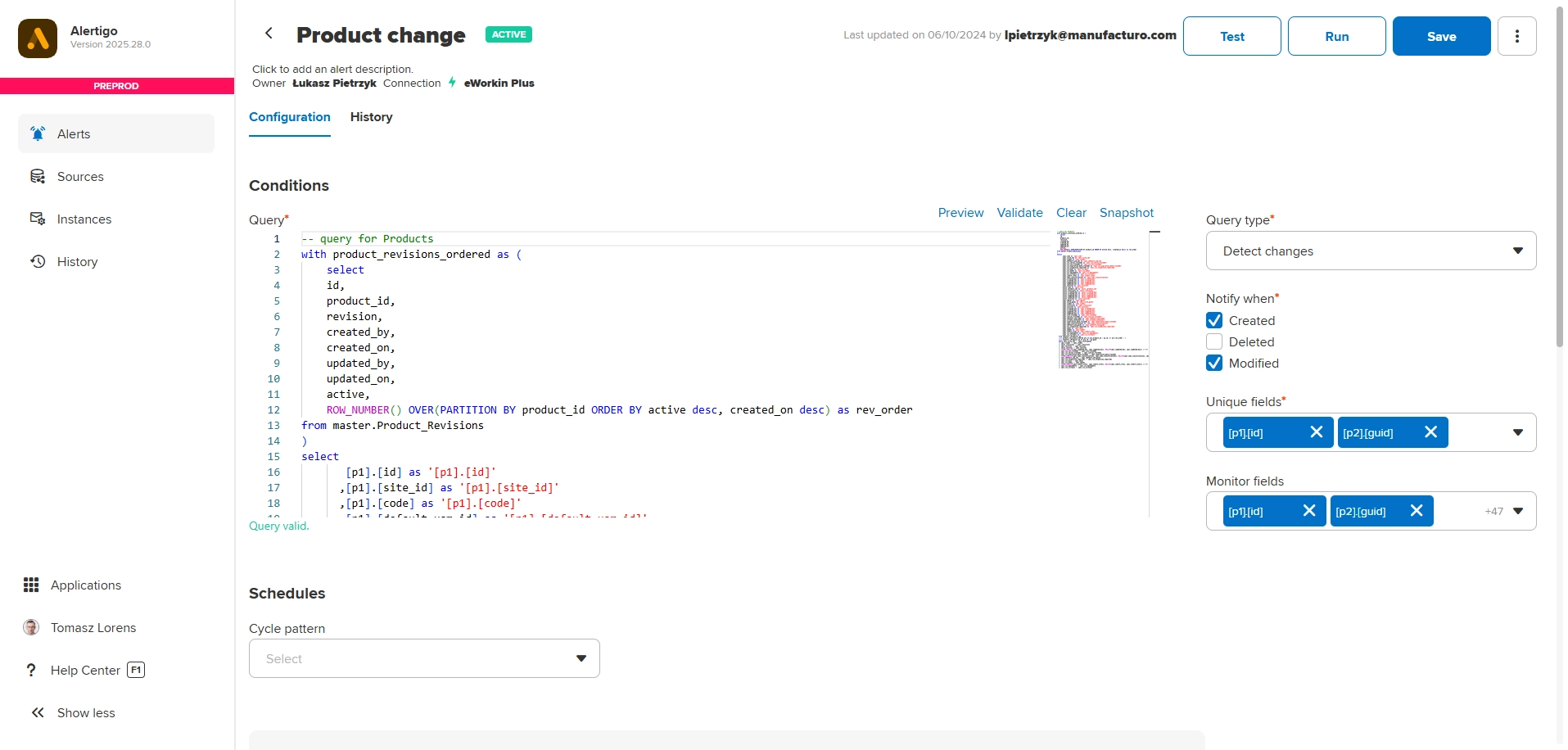

How ALERTIGO works

ALERTIGO connects directly to your data sources and monitors changes or predefined conditions. It triggers alerts when specific events occur, such as:

- Inventory status changes (e.g., from available to blocked).

- Approaching calibration or expiration dates of equipment.

- Assignment of Nonconformance tickets or CAPA tasks.

- Comments or updates on Process Plans or Work Orders.

Alerts can be configured to run on a schedule (hourly, daily, weekly, etc.) or based on real-time data changes, balancing timely notifications with system performance.

Using dynamic templates, ALERTIGO customizes messages with relevant data fields, automatically pulling information to generate clear, actionable alerts via email or SMS.

Key Capabilities

Targeted, actionable alerts

Avoid irrelevant spam by sending the right information to the right people, using rich-text email, SMS, or app notifications.

Configurable triggers

Set alerts based on data changes (create, modify, delete) or scheduled snapshots.

Supports multiple channels

Integrates with your messaging platforms to deliver alerts where your teams already work.

Secure and scalable

Cloud-based architecture supports multisite deployments and enterprise-grade security.

Full visibility

View alert history, including delivery success and failure, for traceability and auditing.

Predefined alerts included

Manufacturo provides essential system alerts (e.g., NC assignments, CAPA updates) by default, ensuring critical notifications remain active.

Designed for high-complexity environments

In complex manufacturing operations, even minor delays or overlooked issues can create downstream disruptions. ALERTIGO helps manufacturers:

Reduce downtime by alerting delays and equipment readiness issues.

Improve quality outcomes by notifying teams about defective parts or process deviations.

Maintain compliance by proactively managing calibration, inspection, and regulatory deadlines.

Enhance decision-making through real-time visibility into risks and operational events.

Integrated with Manufacturo’s MES platform

ALERTIGO is fully integrated within the Manufacturo platform, extending your operational readiness without requiring separate systems. It aligns with your workflows while maintaining a low-touch user experience—alerts are automated, so teams receive timely notifications without needing to interact with the app.

Access to alert configuration is restricted to trained users, ensuring alerts are properly managed and avoiding unnecessary system noise or notification floods.

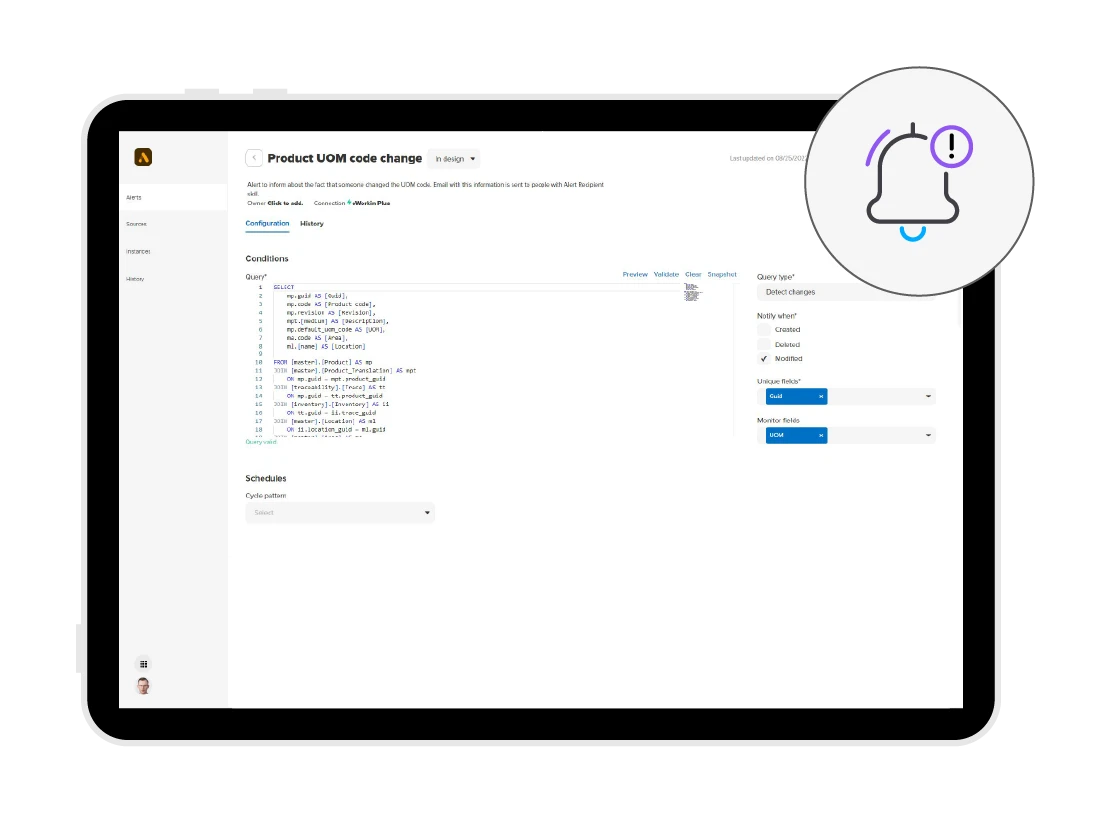

Take a virtual tour

Drive proactivity through early warnings or smart alerts tailored to your needs

Use fully automated data collection to effectively trackdata changes and send immediate alerts when they take place

Check out our other applications

Seamlessly drive your production across all manufacturing models

Streamline your production processes and cut manufacturing costs

Monitor equipment availability, status, maintenance and calibration dates to eliminate inefficiencies

Ensure the right materials are available to meet production demands.

Control all inventory movements and contain defects at every step

Transforms pull-based replenishment into a connected, responsive system.

Eliminate nonconformance issues, mitigate nonconformity risk, and increase regulatory compliance

Effectively manage corrective, preventive, and containment actions and configure custom action types to improve your entire CAPA process

Centralize and control all documents within Manufacturo

Integrated, Transparent Action Tracking for the Shop Floor

Gain enhanced traceability to increase safety and compliance

Embed screens and customize attributes to improve data accuracy, streamline workflows, and increase productivity