The Manufacturo platform provides next-generation applications designed to streamline, accelerate, and optimize manufacturing operations in hi-tech industries. To help you successfully capture and address internal and external audit findings and meet ISO 9001 or AS9100 quality standards, Manufacturo provides a robust CAPA management solution as part of its application suite.

To better support organizations in complex industries, did you know the Manufacturo platform also offers a dedicated Nonconformance Management software that helps you monitor and control the nonconformance process across all manufacturing operations.

Drive continuous quality improvement with Manufacturo’s CAPA

Typically, a CAPA process solution comprises analyzing and reporting capabilities and improving manufacturing operations and production processes to help investigate issues, identify root causes of systemic manufacturing defects, and eliminate repeat nonconformances. The obvious goal of CAPA management is to enable your engineers and operators to execute corrective actions to prevent unexpected issues and unplanned events from reoccurring.

When selecting CAPA software, many companies choose Jira with hopes of using it to control the entire CAPA process. However, while Jira is an effective project management tool, it is not designed for rigid and data-rich workflows. It lacks a proper approval configuration and escalation, transparent tracking of analysis, causes, and associated resolution. Integrations to other required tools and transactions within a manufacturing execution system cannot be effectively established. Manufacturo’s CAPA application eliminates these technical and workflow-related challenges and is intentionally designed for this purpose.

Successfully capture and effectively address external and internal audit findings

Define and enable clear business rules, workflow controls,and approvals for efficient issue management

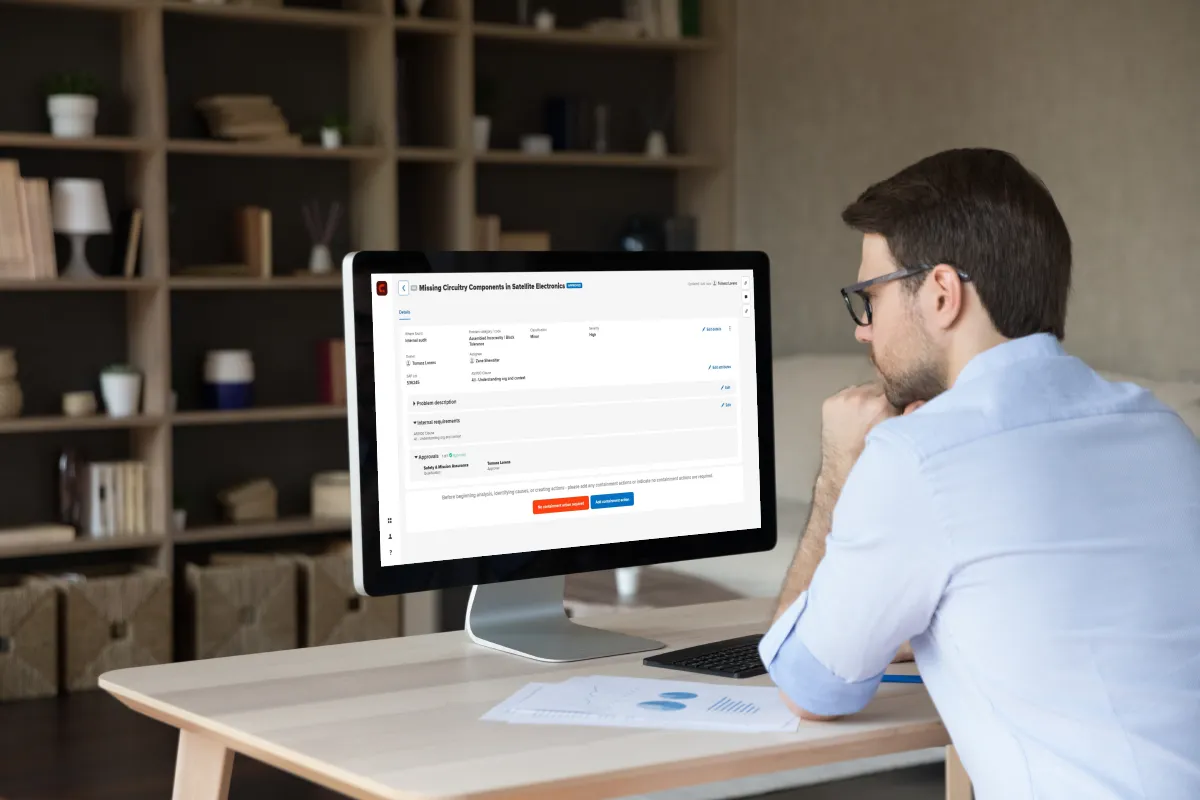

Manufacturo’s CAPA is more than your basic CAPA solution

Having hands-on experience in innovative industries, we know that hi-tech emergent manufacturers like you operate in demanding and complex environments. With advanced and complicated manufacturing processes, you need a powerful and versatile solution to meet your needs.

While other applications may offer useful CAPA functions, Manufacturo’s application takes CAPA and action management to a new level. It supports corrective and preventative actions but integrates containment natively in its workflow and provides unlimited configuration options to classify different types of actions. Our CAPA application integrates with our Nonconformance Management solution to defer further action, root cause analysis, problem source findings, and control transactions within Manufacturo. The ease of integration and compatibility with other Manufacturo modules greatly widens the number of use cases and enables you to leverage it for:

Administrative processes that are causing problems or are not sufficient

Training issues in your organization that need to be investigated and eliminated

A systemic manufacturing issue, unexpected event, or an unanticipated finding on the shop floor

An escape path in your design engineering processes where you are introducing errors into your products and production system

An audit finding you need to proactively contain to find where the rest of the issues are within your organization, all while making sure you’re not missing something relevant or crucial to your audit finding

Blocking incoming receiving until a corrective action is completed or preventing staff members with a specific qualification from clocking into the work order operation until the corrective action is completed

Manufacturing operations that require a greater level of oversight and integration to transactions within a single platform, making the use of standalone solutions or managing CAPA business processes and workflows outside of your MES not effective

Key capabilities that make Manufacturo’s CAPA unique

As the name CAPA suggests, most tools in the market offer standard CAPA capabilities created solely for typical corrective and preventive actions. Manufacturo’s CAPA provides an unmatched level of customization to make all your actions highly flexible to successfully drive, monitor, and measure orchestrated changes within your organization and teams. Our CAPA application’s configurations ensure you can drive any actions needed within the organization.

Suppose your manufacturing operations include processes unique to your sector or product. In that case, you can add different CAPA project and action types to drive other workflows and leverage conditional-based approvals and escalations. For example, if you needed to create a different project type, you could run other types of actions specific to your nuanced use cases.

Manufacturo’s CAPA enables you to:

- Create and approve CAPA projects

- Submit projects for evaluation

- Add active containment and other high-priority actions, e.g., impact assessment

- Create and manage corrective and preventive actions

- Investigate and identify causes

- Report problems and failures

- Perform analyses

- Create, approve, and execute any actions configured and customized to your specific needs, e.g., supplier corrective action reporting or general process improvement actions

- Link multiple nonconformances to the CAPA project to achieve a clear trace between the defect and the investigation and link cause and problem source findings back to the nonconformance record

- Collect objective evidence of effectiveness for implemented actions

- Prioritize and rank causes and associated actions using integrated risk assessment

- Customize attributes, comments, and tags

- Attach files

- Add external links

Analysis tools and methods you need to find the root cause and drive CAPA workflow

For a CAPA management toolkit to adequately support your business and manufacturing operations, it needs to facilitate issue investigation and analysis. Manufacturo’s robust CAPA management solution comes with a variety of tools, methods, and best practices to ensure effective analysis and your standard and custom CAPA actions are effective.

CAPA analysis methods enable you to capture results and identify causes of various types, depending on your business needs (e.g., direct cause, contributing cause, root cause). Perform 5 Whys, capture Fishbone diagrams, execute a failure mode effects and criticality analysis (FMECA), build a fault tree, run a Pareto statistical analysis – and more.

CAPA ensures you can efficiently analyze a problem, define a cause, including its organizational risk and its source, and link it with actions to ensure once they are implemented, the cause is fully mitigated or eliminated.

Why Manufacturo’s CAPA is an integrated CAPA solution designed for complex industries

Hi-tech emergent manufacturers in complex industries, such as aerospace or defense, need a CAPA management solution for various reasons, including internal and external audits or ISO 9001 and AS9100 compliance. These companies often work with or for the government and interact with federal agencies, which means they are often audited and monitored.

If you operate in this space, you need to control what problems require CAPA and what doesn't because not all problems and issues should be reported in a CAPA management system. With CAPA, you define and enable clear business rules, approvals, and workflow controls to manage what problems require CAPA and which do not. You also get integrated corrective, preventative, and containment actions that provide nearly unlimited potential with direct integration to transaction control within the Manufacturo platform.

CAPA workflow ensures you follow a structured, clear, controlled, and intuitive process from problem identification, analysis, cause identification, action definition and implementation, and objective action evaluation to project closure. No cause is left behind – you can rest assured your cause findings are linked with effective implemented actions through our explicit decision framework that eliminates implied and ambiguous decisions and information.

Successfully capture and effectively address external and internal audit findings

Define and enable clear business rules, workflow controls,and approvals for efficient issue management

Check out our other applications

Seamlessly drive your production across all manufacturing models

Streamline your production processes and cut manufacturing costs

Monitor equipment availability, status, maintenance and calibration dates to eliminate inefficiencies

Ensure the right materials are available to meet production demands.

Control all inventory movements and contain defects at every step

Transforms pull-based replenishment into a connected, responsive system.

Eliminate nonconformance issues, mitigate nonconformity risk, and increase regulatory compliance

Effectively manage corrective, preventive, and containment actions and configure custom action types to improve your entire CAPA process

Centralize and control all documents within Manufacturo

Integrated, Transparent Action Tracking for the Shop Floor

Gain enhanced traceability to increase safety and compliance

Gain holistic visibility to predict, identify, and eliminate potential issues before they become critical blockers

Embed screens and customize attributes to improve data accuracy, streamline workflows, and increase productivity