Total control over every part, container, and movement—at every stage.

Inventory connects procurement, production, and fulfillment—but when data is fragmented, it disrupts traceability, delays output, and complicates quality control.

Manufacturo’s Inventory suite solves these problems by providing an end-to-end system of record for all material movement, trace events, and location updates—spanning high-level oversight to hands-on execution.

Our PLM integration with Manufacturo is super seamless and has been incredibly powerful, in terms of the speed tenant...at the beginning of the product lifecycle an engineer can release a part [in PLM] and it's instantaneously pushed to Manufacturo with all its BOM (Bill of Materials) components, as well, which has been another cornerstone of our success here...

Ellen Malloy

The solution includes Inventory Management and Inventory Operations. Together, they enable real-time accuracy, barcoded efficiency, and audit-ready traceability across every touchpoint.

Inventory Management

For supervisors analyzing flows and managing data across locations. Beyond data oversight, Management also boasts operational functions like label reprints, de-allocations, and quantity adjustments, enabling teams to act immediately when issues arise.

Inventory Operations

For on-the-ground handlers executing transactions via mobile tablets. Operations enables barcode-driven receiving, locating, transferring, and issuing of inventory, along with label reprints and cycle counts—keeping inventory accurate and traceable without slowing down the floor.

Key Capabilities

Real-Time Inventory Visibility

Gain complete visibility into every item—from receipt to consumption to shipment. Track inventory down to individual parts, serial numbers, containers, and locations, with a clear record of every movement and transaction. View and manage these details directly from the shop floor or central dashboard.

Split UI for Strategy and Execution

Unlike competitors that compress all inventory tasks into a single desktop app, Manufacturo separates strategic management from mobile execution. This tailored experience ensures speed, accuracy, and usability for each user role.

Barcode-Driven Efficiency

Use smart iTag barcodes to instantly capture trace details, locations, statuses, and part data with a single scan—no manual entry required.

Connected Traceability

Inventory activity is automatically linked to work orders, quality events, and shopfloor execution—ensuring continuity and trace history across builds.

Inventory Operations on Mobile

Warehouse staff use tablets and built-in barcode scanning to execute daily tasks—receiving, putaway, kitting, picking, and moves. Smart scanning minimizes clicks and automates data entry by recognizing fields like serial number, location code, and order reference.

Typical Mobile Tasks Include:

- Scanning received inventory and assigning it to containers and locations

- Performing inventory transfers within your plant by scanning shelf QR codes

- Assembling kits by scanning components to a picking container

- Recording location transfers in real time

- Reprinting labels directly from the shop floor when needed

Integrated Quality Status Control

Track inventory by status:

- Available – ready for use

- On Hold – pending inspection, verification, disposition, or processing

- Blocked – needs return/scrap

Quickly adjust status in batches or by container, linked to quality workflows.

Common Use Cases

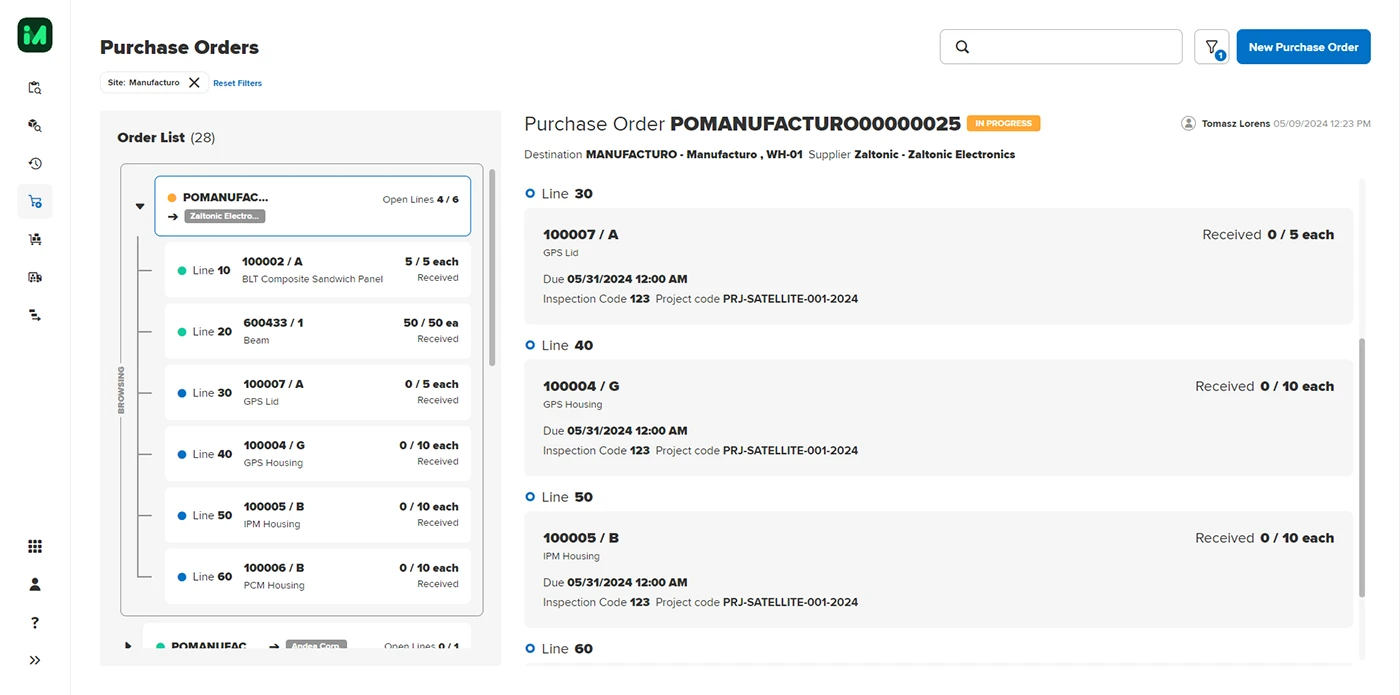

- Receive and inspect purchased goods

- Allocate/deallocate inventory to work orders or shipments

- Adjust quantities, split/merge containers, or track usage history

- Change inventory status based on inspection outcomes

- Transfer inventory across plants with full traceability

- Return materials to vendors or customers

- Perform cycle counts and reconcile discrepancies

Unified Inventory Control Across the Lifecycle (see the diagram)

Supporting Applications

Inventory Management

Desktop-based control for supervisors managing inventory levels, flows, and strategic decisions.

Inventory Operations

Mobile-first tools enabling handlers to scan, move, and confirm material in motion across the plant.

Kanban Management

Visual tool to support pull-based inventory replenishment and loop performance.

Take a virtual tour

Learn more about Manufacturing Inventory Management

Check out our other applications

Seamlessly drive your production across all manufacturing models

Streamline your production processes and cut manufacturing costs

Monitor equipment availability, status, maintenance and calibration dates to eliminate inefficiencies

Ensure the right materials are available to meet production demands.

Transforms pull-based replenishment into a connected, responsive system.

Eliminate nonconformance issues, mitigate nonconformity risk, and increase regulatory compliance

Effectively manage corrective, preventive, and containment actions and configure custom action types to improve your entire CAPA process

Centralize and control all documents within Manufacturo

Integrated, Transparent Action Tracking for the Shop Floor

Gain enhanced traceability to increase safety and compliance

Gain holistic visibility to predict, identify, and eliminate potential issues before they become critical blockers

Embed screens and customize attributes to improve data accuracy, streamline workflows, and increase productivity