Optimize Replenishment with Manufacturo’s Kanban App

Real-Time Material Flow, Automated Pull Systems, Zero Guesswork

In complex manufacturing environments, even small disruptions in material flow can sprial into production delays, resource bottlenecks, and inventory imbalances. Traditional Kanban systems—built on paper cards, whiteboards, or siloed digital tools—offer visibility, but not reliability.

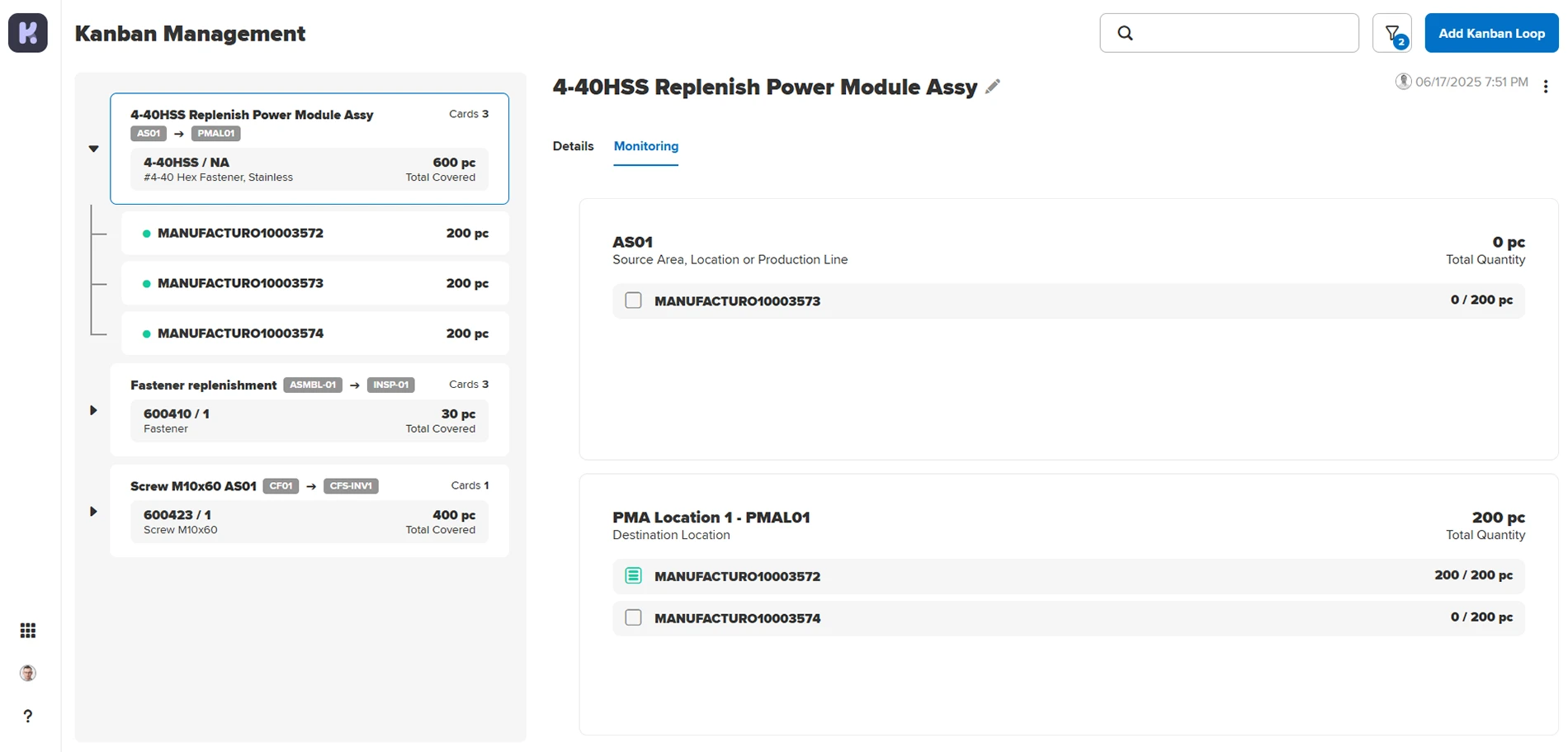

Manufacturo’s Kanban App transforms pull-based replenishment into a connected, responsive system.

Purpose-built for high-mix, high-velocity operations, the Kanban App digitizes material movement from stockroom to line-side. It provides real-time visibility, automates execution, and ensures that every part and container stays in sync with production demand.

Why Legacy Kanban Systems Fall Short

Traditional Kanban systems provide visual cues—but no real-time coordination. As a result, manufacturers face issues like:

- Manual execution delays – Operators must trigger replenishment manually, often using paper cards or disconnected scanners

- Poor flow visibility – No centralized way to monitor bin status, card location, or quantity in transit

- Inconsistent execution – Replenishment loops often break down due to unclear ownership or siloed systems

- High risk of production stoppage – If the wrong container isn’t in the right place at the right time, everything slows down

In high-complexity environments, these gaps add up to real losses—missed deadlines, wasted effort, and escalating operating costs.

Manufacturo’s Kanban App eliminates these risks by providing a closed-loop, digital system that automates replenishment flows, tracks inventory movement in real time, and ensures continuous material availability.

Key Capabilities That Improve Flow and Reduce Waste

Closed-Loop Replenishment Without Guesswork

Automatically move materials where they’re needed, when they’re needed. Whether you’re triggering replenishment or returning containers for refill, Kanban cards drive a predictable, traceable pull system—reducing the risk of shortages, overstock, or missed handoffs.

Benefits:

- Ensures consistent material availability at the line

- Minimizes inventory holding costs and excess WIP

- Aligns replenishment cycles with real-time demand

Real-Time Visibility Into Every Container and Card

Track Kanban cards and their associated containers across every stage—from source to destination, in transit, or at rest. Status indicators provide clear insight into what’s active, paused, or awaiting action.

Benefits:

- Prevents miscommunication and unplanned downtime

- Enables fast response to flow disruptions

- Provides a live view of material readiness across the floor

Configurable Logic That Adapts to Your Operations

Tailor loops to match your production environment: set quantities, lead times, and destinations. Whether you’re managing high-mix assembly or volume-driven replenishment, the system adapts to your needs.

Benefits:

- Supports lean initiatives and production variability

- Reduces manual intervention and human error

- Improves alignment between planning and execution

Native Integration With Inventory and Execution Systems

Kanban isn’t an add-on—it’s embedded in Manufacturo’s broader manufacturing system. Every card, move, and bin action ties into inventory, shop floor operations, and planned move logic—giving you one coordinated flow of materials.

Benefits:

- Eliminates silos between planning, inventory, and operations

- Increases system reliability and traceability

- Reduces reliance on spreadsheets or third-party tracking tools

Take a Virtual Tour to See Our Software in Action

Explore how the Kanban App fits into your real-world operations and drives better replenishment performance.

Gain Full Control Over Material Flow

Automate your pull system and eliminate the delays and errors of manual Kanban. With Manufacturo, every bin, card, and move order is part of a unified, responsive flow.Check out our other applications

Seamlessly drive your production across all manufacturing models

Streamline your production processes and cut manufacturing costs

Monitor equipment availability, status, maintenance and calibration dates to eliminate inefficiencies

Ensure the right materials are available to meet production demands.

Control all inventory movements and contain defects at every step

Eliminate nonconformance issues, mitigate nonconformity risk, and increase regulatory compliance

Effectively manage corrective, preventive, and containment actions and configure custom action types to improve your entire CAPA process

Centralize and control all documents within Manufacturo

Integrated, Transparent Action Tracking for the Shop Floor

Gain enhanced traceability to increase safety and compliance

Gain holistic visibility to predict, identify, and eliminate potential issues before they become critical blockers

Embed screens and customize attributes to improve data accuracy, streamline workflows, and increase productivity