An advanced, modernized manufacturing document management system can greatly enhance productivity by providing real-time document visibility, optimizing compliance processes, and streamlining manufacturing document management. The best manufacturing document management software solutions also offer key performance indicator (KPI) tracking while integrating seamlessly with ERP and WMS systems, ensuring that businesses maintain up to date documentation at all times.

Regardless of whether manufacturing operations involve high-volume production or intricate manufacturing processes, implementing effective document control software boosts overall operational efficiency, minimizes compliance risks, and enhances document security. By automating workflows, reducing reliance on paper documents, and improving document accessibility, manufacturers can significantly enhance their quality and document control systems.

Understanding Document Control Software

Manufacturing document control software is designed to optimize document management processes, minimize compliance risks, and garner stronger information governance. A manufacturing company can also enhance customer satisfaction and witness cost savings connected to enhanced product quality and deliverables thanks to effective document management that allows for tracking revisions and meet compliance requirements. These tasks that are far slower and more prone to error with an outdated system that relies in part or completely on physical document storage.

Additionally, when integrated with ERP and WMS systems, document control software for manufacturing centralizes critical documentation, enhancing coordination between teams with up to date information- a major benefit given that manufacturing processes require collaboration.

Key Advantages of Document Control Software

Real-Time Visibility & Monitoring

Immediate access to documentation is essential for manufacturing document control.

Manufacturing document management systems provide:

- Real-time dashboards with insights into document status, access history, and version control.

- A digital repository that eliminates paper documentation reducing clutter and ensuring security.

- Enhanced quality and document control for improved operational transparency.

- Instant access to critical documents so teams can retrieve information quickly.

- Automated alerts with document updates, expirations, or required reviews.

Efficient Document Organization & Accessibility

Managing a large volume of manufacturing documents requires an efficient system that enables:

- Centralized Repository: Stores and categorizes all essential documents, ensuring easy retrieval.

- Version Control: Maintains a clear history of document revisions and approvals, preventing outdated documents from causing errors.

- Document Sharing: Facilitates collaboration across cross-functional teams and enables real-time document sharing between departments.

Ensuring Compliance & Regulatory Adherence

A digitized document management system provides crucial advantages related to compliance and regulations:

- Automated Compliance Checks: Ensures documents align with regulatory requirements such as FDA 21 CFR Part 11, ISO 13485, and AS9100.

- Audit Trails: Maintains a complete audit trail of document access and modifications.

- Secure Document Storage: Prevents unauthorized access and ensures data security.

- Regulatory Standards Compliance: Ensures manufacturing document management meets industry standards and tracks compliance documents with ease.

- Immutable Blockchain-Backed Records: Enhances compliance verification by ensuring that documents remain tamper-proof.

Data-Driven Decision-Making

A comprehensive document management system enhances data utilization by tracking essential KPIs such as:|

- Document Access Metrics: Tracks how often documents are used and who accesses them.

- Compliance Reporting: Automates reports on document retention and security compliance.

- Process Optimization: Identifies bottlenecks in document control workflows and suggests improvements.

- Data Consistency: Ensures that document revisions align with operational needs and company policies.

- Predictive Compliance Risks: Uses AI-driven analytics to identify potential regulatory risks before they impact production.

Reducing Risk & Enhancing Security

Managing sensitive manufacturing documents requires robust security measures, which an advanced manufacturing document control system provides through:

- User Access Controls: Restricts access to authorized personnel only.

- Encryption & Backup: Protects confidential documents from data breaches.

- Workflow Automation: Reduces human errors and enforces strict security protocols.

- Zero-Trust Architecture: Implements multi-layered access verification, ensuring only approved users can access high-security documents.

A Configurable Approval Workflow

Standard Manufacturing vs. High-Complexity Manufacturing Document Management System Needs

Unique Challenges in High-Complexity Manufacturing

Industries like aerospace, medical devices, and defense demand advanced manufacturing document control due to strict governmental regulations and complex workflows. Key requirements include:

- Regulatory Compliance & Audit Readiness: Ensuring adherence to ISO, FDA 21 CFR Part 11, AS9100, ITAR, and NIST 800-171.

- Advanced Document Management: Maintaining a centralized repository with version control and audit trail tracking.

- Security & Access Control: Protecting business critical documents with encryption, role-based access, and blockchain verification.

Specialized Document Control Solutions

High-complexity manufacturers require efficient document management software with features tailored to their needs:

- Automated Compliance Mapping: Tracks overlapping regulations and auto-updates documents.

- AI-Powered Workflow Automation: Detects compliance risks and flags deviations in real time.

- Multi-System Integration: Links PLM, MES, and ERP for seamless data flow.

- Global Scalability: Supports multi-location operations and multi-language compliance tracking.

Standard Manufacturing Needs

For standard manufacturers, effective document management systems focus on efficiency and accessibility with simpler workflows:

- Basic Compliance Tracking: Covers ISO 9001 and general industry regulations.

- Streamlined Document Approvals: Uses rule-based automation instead of AI-driven compliance mapping.

- Local Document Storage: Prioritizes manufacturing document control with role-based permissions.

Selecting the Right Document Control Software for Your Business

To maximize efficiency and compliance, manufacturers should consider:

- Document Complexity: Does the system support both simple and complex document workflows?

- Integration Capabilities: Can it connect with ERP, MES, PLM, and other enterprise tools?

- Scalability: Will it grow with business needs and regulatory demands?

- Regulatory Compliance: Does it maintain audit trails and support digital record-keeping to meet industry standards?

Investing in the right document management system ensures long-term operational success, security, and compliance.

Common Key Features

Most manufacturing document management systems share core functionalities essential for document control and compliance:

- Real-Time Document Tracking – Monitoring document status, revisions, and approvals for quality processes and relevant documents.

- Version Control – Managing changes with clear audit trails and preventing outdated document use.

- Access Control & Security – Restricting document access to authorized personnel and maintaining data integrity.

- Automated Workflows – Streamlining document approval processes to reduce manual errors.

- Reporting & Compliance Audits – Generating compliance reports and tracking key performance indicators (KPIs) related to regulatory requirements.

- System Integration – Seamless connectivity with ERP, MES, PLM, and financial platforms for a centralized document repository.

Unique Features

While most document management systems offer standard capabilities, some include additional functionalities to meet specific business needs:

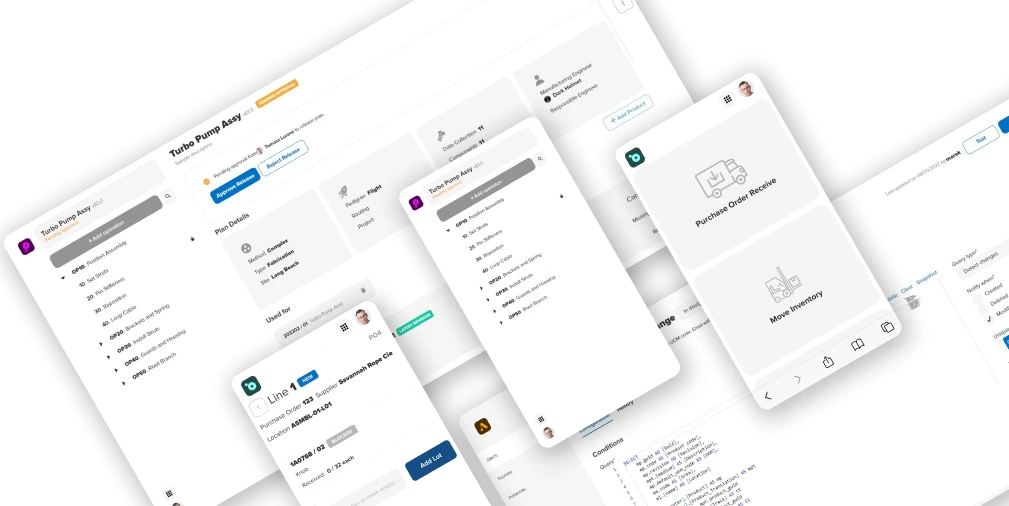

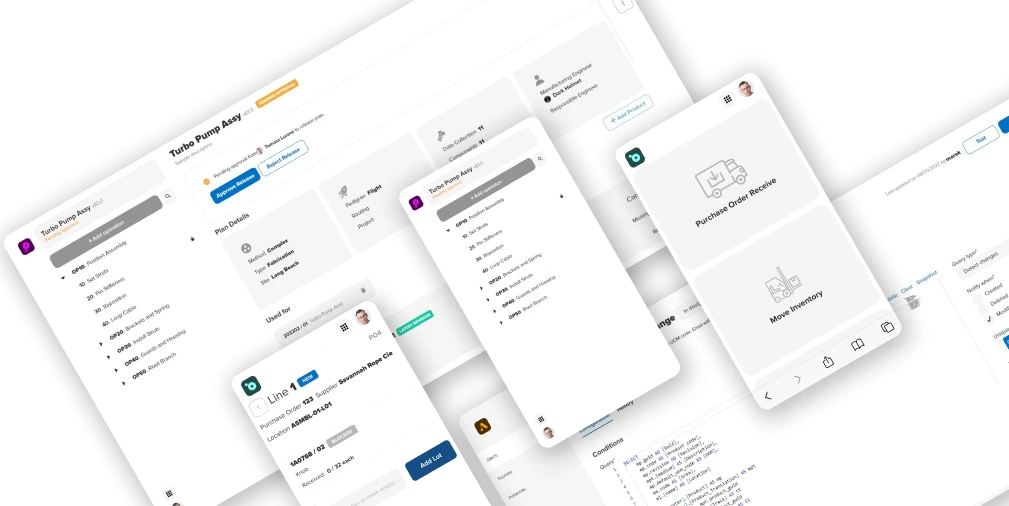

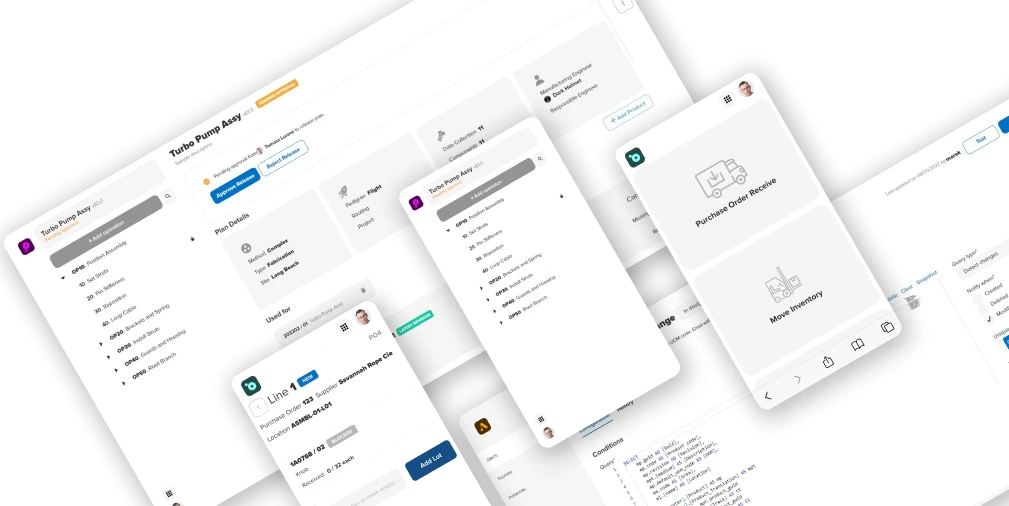

- Mobile Accessibility – Secure access to documents from any device.

- Customizable Dashboards – Tailored document control interfaces for different user roles.

- Automated Compliance Monitoring – AI-driven analysis to ensure improved regulatory compliance.

- Cloud-Based Integration – Secure document storage and backup with global access.

- Advanced Search & Retrieval – AI-enhanced indexing for quick document retrieval across multiple systems.

- Digital Signatures & Approvals – Ensuring authenticity and compliance with government regulations.

Fast, Accurate Document Management

Comparative Analysis of Document Control Solutions

A comparative analysis of manufacturing document control systems highlights areas of consensus and differentiation:

Areas of Consensus

-

Real-Time Data Access – Every system prioritizes live document tracking and compliance reporting.

-

Seamless Integration – Most solutions connect with ERP, CRM, and compliance platforms to unify document management.

-

User-Friendly Interfaces – Accessibility and ease of use remain critical for adoption and managing documents related to compliance and efficiency.

Key Differences

- Customization Levels – Some solutions provide highly configurable document workflows, while others offer pre-built templates.

- Industry-Specific Features – Certain platforms cater to high-complexity manufacturers, while others focus on small-to-medium enterprises.

- Advanced Automation – Not all manufacturing document management systems include AI-driven risk analysis or predictive compliance tracking.

Comparison of Document Control Software: Manufacturo vs. Other Leading Solutions

Manufacturers and enterprises seeking robust document control software have a wide range of options to streamline compliance, version control, and workflow automations. Below is a comparative analysis of Manufacturo alongside other leading providers of traditional and niche MES systems.

Document Management & Version Control

- Best for Secure Archiving & Instant Access: DocuWare and SmartVault offer centralized document repositories with powerful search functions, real-time access, and robust version tracking.

- Manufacturo’s Advantage: Provides a fully integrated Document Management (DM) system with version-controlled document storage, allowing organizations to manage, reference, and reuse document content across various processes. Includes document code prefix/suffix management and detailed approval workflows.

Regulatory Compliance & Audit Trails

- Best for Compliance-Driven Industries: MasterControl and ETQ Reliance specialize in compliance with ISO, FDA 21 CFR Part 11, and AS9100, ensuring strict audit trails and access control.

- Manufacturo’s Advantage: Supports automated compliance tracking with integrated document review, approval workflows, and traceability. The system allows organizations to define approval qualifications and track document changes to meet regulatory requirements.

Workflow Automations & Collaboration

- Best for Seamless Workflow Integration: DocuWare and SmartVault provide advanced workflow automations, enabling real-time collaboration and secure document access and sharing across teams.

- Manufacturo’s Advantage: Features a Document Dashboard that provides real-time status updates on documents, responsibilities, and changes, allowing for enhanced traceability. Custom attributes and mandatory fields ensure documents align with organizational needs.

Document Storage & File Format Support

- Best for Broad File Type Support: ShareFile and SmartVault allow businesses to upload various document types, including PDFs, images, and ZIP files, for flexible document management.

- Manufacturo’s Advantage: Supports multiple file formats, including ZIP, PDF, JPG, PNG, TIFF, and WEBP, ensuring compatibility with diverse documentation needs. Documents can be linked directly to work orders and integrated into manufacturing processes.

ERP & System Integration

- Best for ERP & Manufacturing Integration: DELMIAWorks integrates document control with manufacturing ERP systems for seamless connectivity across business functions.

- Manufacturo’s Advantage: Integrates directly with enterprise-wide processes, linking documents to work orders, procedures, and quality management systems, ensuring document traceability across operations.

Scalability & Industry Focus

- Best for Small & Medium Businesses: SmartVault, ShareFile, and DocuWare cater to organizations requiring cloud-based, scalable document management solutions.

- Manufacturo’s Advantage: Designed for high-tech and compliance-driven industries, such as aerospace, defense, and medical manufacturing, supporting multi-site scalability and enterprise-wide document governance.

Use Cases and Industry Applications

Document control software is widely adopted across various manufacturing operations, including the following high-complexity industries:

An aircraft manufacturer integrates document control software to track engineering drawings, ensure FAA compliance, and allow engineers to collaborate effectively.

A military equipment manufacturer uses document control software for manufacturing to comply with ITAR regulations, secure sensitive data, and provide instant access to compliance documents for audits and inspections.

A surgical implant producer employs document management software to ensure FDA and ISO 13485 compliance, track device manufacturing history, and maintain up to date records.

A leading automotive manufacturer integrates manufacturing document management to store and manage maintenance manuals, streamline supply chain documentation, and ensure compliance with industry safety standards.

A private space launch provider uses manufacturing document control systems to manage propulsion system documentation, track revision history, and ensure traceability for mission-critical components.

Key Insights and Emerging Trends in Document Control

Several trends are shaping the future of document control for manufacturing companies:

- Cloud-Based Solutions – Adoption of cloud-based document management systems is increasing due to enhanced security, global accessibility, and seamless integration with enterprise platforms.

- Mobile Accessibility – Growing demand for mobile-friendly document control solutions that enable remote document access and approvals.

- AI and Automation – AI-driven compliance tracking and automated workflows are streamlining document approval and version control processes.

- Customization and Modular Design – Businesses seek manufacturing document management software that adapts to industry-specific compliance and security needs.

- Real-Time Alerts and Notifications – Automated alerts ensure timely document updates for quality assurance and operational efficiency.

- Advanced Security Measures – Increased focus on role-based access control, encryption, and audit trails to protect intellectual property and maintain compliance with governmental regulations.

Conclusion

Manufacturing document management software is a vital for manufacturing companies today and tomorrow. Ensuring that all your documents and critical information are stored in a single location with proper access controls and authorized users enables manufacturing excellence is more than a competitive advantage - it is part and parcel to process efficiency and the digital transformation.

Whether managing product blueprints, quality documents, or operational procedures, document management software provides the necessary tools for the long-term success of any type of manufacturing company. By leveraging real-time document collaboration, automated workflows, and data-driven insights, businesses can elevate their manufacturing document management and ensure seamless document control processes across all operations. The integration of document control software for manufacturing enables companies to maintain compliance documents, enhance security, and achieve manufacturing excellence through continuous improvement strategies.

Single Source of Truth