To facilitate robust manufacturing traceability from the planning phase, through shop-floor operations, all the way to as-built reports, Manufacturo MES software provides a set of out-of-the-box applications that enhance product control and eliminate quality issues.

To learn more about production process management solutions, visit Manufacturo MES software. The following are details on One View Genealogy that helps manufacturing engineers and shop-floor operators achieve complete traceability of all components and parts at every stage of manufacturing operations.

How Manufacturo MES software simplifies product traceability efforts

Hi-tech emergent companies, whose operating costs and mandatory standards are more demanding than in volume production, need an effective manufacturing traceability software to efficiently track commonly occurring engineering changes. Since even a single modification can result in deviations from the original design, rework and repair are frequently required. This means that manufacturers in hi-tech emergent market need a solution that will successfully enable them to understand what has been changed from the original design, track it, and report it. With its manufacturing traceability module, Manufacturo provides real-time production traceability to ensure the highest product quality control even in the most demanding shop-floor environment.

Gain complete traceability of all components and parts at every production stage

Use a single view of all process data to ensure enhancedproduct traceability across the entire supply chain

One View Genealogy enables manufacturers to:

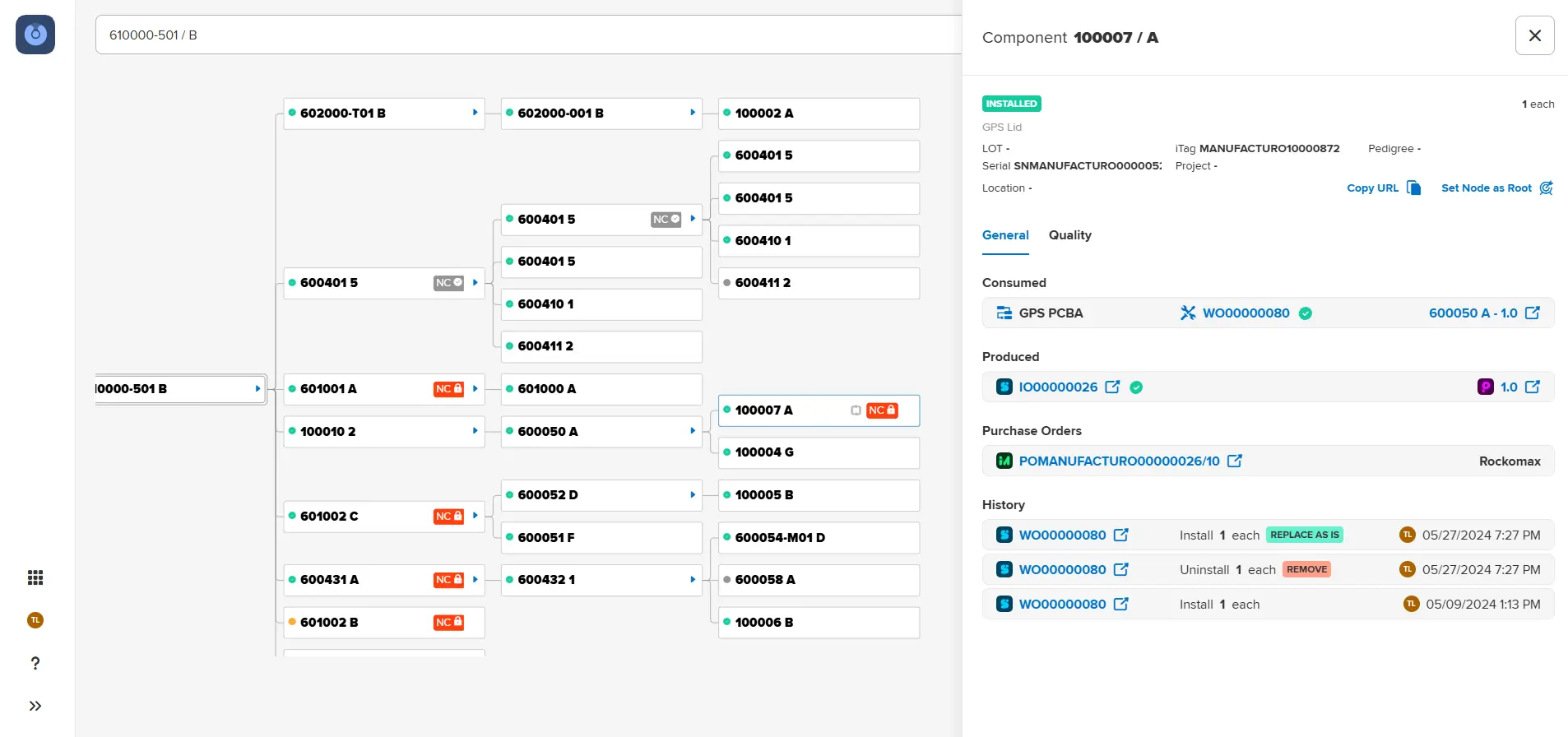

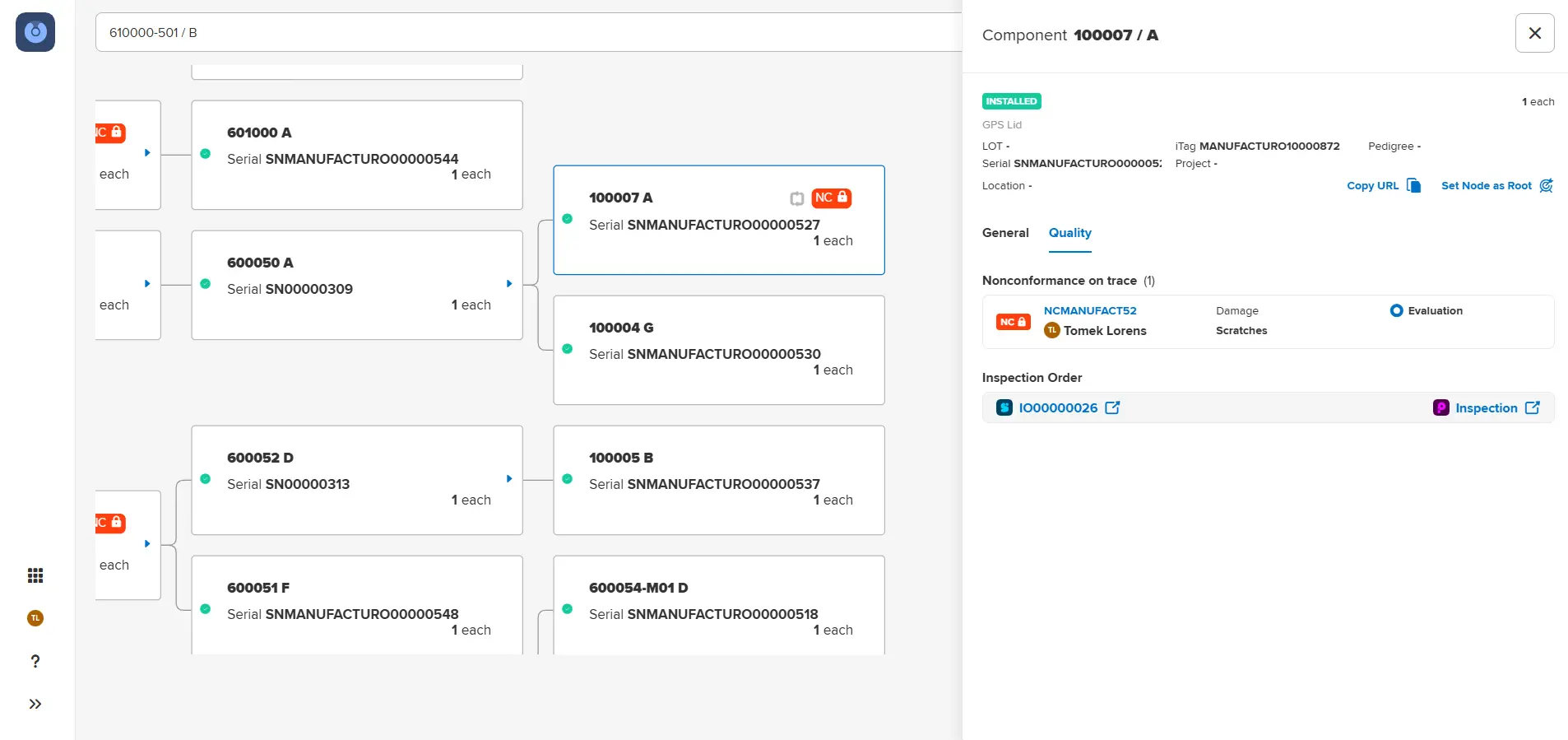

Quickly understand and gain overall visibility on the status of entire assembly to see what's been built so far, where is the entire built, and how much is left.

Check the percentage of completion of the entire assembly.

Consolidate all key information from production, inventory, and quality to generate the one view of the assembly.

Control multilevel and multisite as-built genealogy traceability from top to bottom and the other way around to quickly identify problematic trace information such as serial or lot.

See “Where Used” feature to identify potential containment scope by navigating through the as-built from the bottom to the top.

Understand all the changes through the Redlines and Engineering Change Notice (ECN) and reconcile the mBOM as-designed vs. as-built genealogy.

Capture As-Maintained to gain the whole picture of the life cycle and better understand Point-in-Time As-Maintained genealogy.

Note:

Improve traceability standards to better control manufacturing processes

Modern manufacturing tracking systems are often overly complicated, forcing manufacturing businesses to train or hire new skilled specialists rather than achieve full digital transformation. On top of it, the data these systems collect is frequently fragmented, preventing engineers and operators from making accurate and instant decisions. For an automated production process to drive agility, cost reduction, and quick return on investment, it needs to provide valuable insights that are easy to view, understand, interpret, and act upon.

The Manufacturo One View Genealogy feature provides a single view of all process data to ensure enhanced product traceability across the entire supply chain, leading to swift quality inspection from raw materials to finished products.

How robust product traceability increases production efficiency

Business and operating models are different in mass production and complex manufacturing. To attain tangible benefits and accelerate speed to market, hi-tech emergent manufacturers need a product tailored traceability application that ensures integrated, automated, end-to-end traceability of components across complex, multilevel assembly lines.

To effectively implement a manufacturing traceability solution that helps improve product quality, manufacturers first need to identify and control their data entry points. Improving product traceability can only be successful when data from various systems is collected and integrated into a single source. Only then, engineers, quality inspectors, supervisors, and managers can gain end-to-end visibility of the assembly and capitalize on insights provided by the single source of truth.

Controlled traceability processes

A holistic overview from raw materials, through components and parts, to finished product will help manufacturers benefit from enhanced product traceability and accurately measure manufacturing progress against targets.

Reduced compliance costs

An automated production process based on product tailored traceability will lower the cost of compliance with standards and regulations around validation, traceability, and quality at every stage of the manufacturing operations.

Increased speed to market

A customized out-of-the-box, easily configurable production traceability software will greatly simplify monitoring of nonconformities and quickly reduce time for managing containments to increase speed to market for hi-tech products.

An end-to-end traceability solution to easily track products and components

Manufacturo One View Genealogy provides integrated traceability to ensure consistent quality control and regulatory compliance across increasingly complex, automated, and agile manufacturing processes. Tracking and monitoring defective products, parts, and components using Manufacturo's traceability feature enables manufacturers to:

-

Maintain consistent quality control across increasingly diverse and dispersed manufacturing lines

-

Chart the impact of changes to components to adequately monitor all stages of the manufacturing process

-

Streamline change management, enabling agile innovation and accelerating time to market

-

Reduce the cost of compliance with quality, sustainability, and safety regulations

-

Track manufacturing progress across every stage to mitigate the risk of exceeding project budgets or timelines

-

Gain transparency and traceability for environmental, social, and governance (ESG) priorities and commitments

-

Leverage track-and-trace solutions across high-volume, fully automated production lines to facilitate derisking of industrial automation

A single view to ensure safety, sustainability, and process improvement

Manufacturers in the hi-tech emergent market apply and implement traceability methods to keep control of all manufacturing operations from planning all the way to generating as-built reports. With One View Genealogy, engineers and operators use available insights to collaborate in real time and effectively monitor, analyze, and react to improve quality and safety of processes and products. Manufacturo’s manufacturing traceability module provides complete transparency and visibility across all operations by:

Facilitating a streamlined, secure audit trail for regulators through a single digital thread, tracing end-to-end product history with photographic evidence.

Identifying defective tools or components by charting all minor or major manufacturing events from redlines to inventory movements.

Helping enforce safety and sustainability standards through live full-spectrum visibility of multitiered assembly processes.

Monitor and analyze all manufacturing processes from end to end and in real time

Achieving traceability across all multitiered manufacturing models and from raw materials to final product is something hi-tech emergent manufacturers want and need. End-to-end traceability data including parts assembly, installation, and history provides valuable insights that not only drive agility but also improve communication between stakeholders and shop-floor operators. And with Manufacturo's manufacturing traceability solution it all happens in real time.

One View Genealogy:

-

Enables manufacturers to track progress against targets and quality inspection

-

Allows for adjusting processes, parts, and components in real time to accelerate speed to market

-

Helps thoroughly analyze impact of all manufacturing events on product quality to safely implement manufacturing changes

-

Increases control of manufacturing progress against business objectives by accurately tracking all stages from subassemblies to finished product

-

Drives innovation through end-to-end overview of evolution from as-designed to as-built and as-maintained

Gain complete traceability of all components and parts at every production stage

Use a single view of all process data to ensure enhancedproduct traceability across the entire supply chain