Quality Assurance from Detection to Resolution

Maintain Flow While Resolving Issues Quickly and Confidently

In complex manufacturing environments, disconnected or manual NC processes lead to unneeded delays, recurring issues, and audit exposure. With teams relying on siloed systems, critical issues slip through the cracks, complicating resolution and root cause analysis.

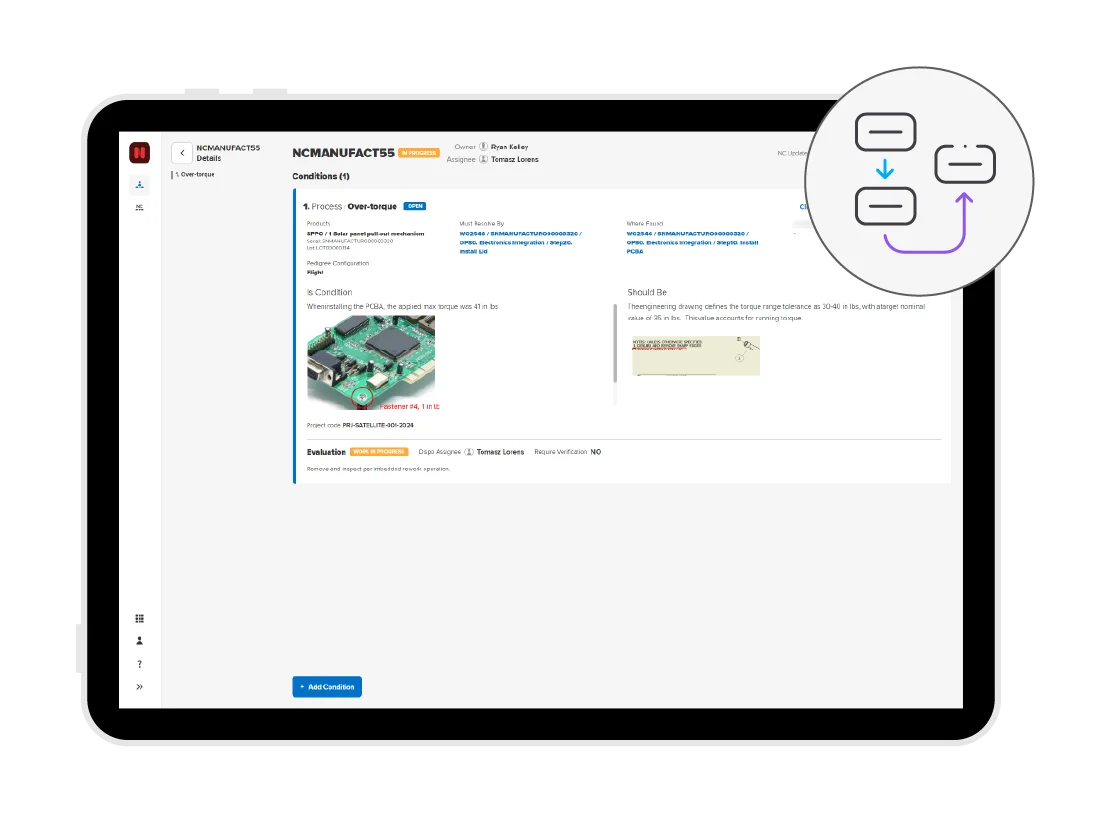

Manufacturo’s Nonconformance app is not a layered-on solution; it embeds quality oversight directly into production and inventory workflows, so that every NC is captured, traced, and resolved quickly. Workflows are structured and rule-based, so operations retain integrity and efficiency.

With Manufacturo’s nonconformance solution, we can quickly and reliably pinpoint any root cause of nonconformance instances and perform a process failure modes effects analysis (PFMEA)….having a clear nonconformance or issue ticket system to be able to track any deviations or nonconformances on the aircraft, we were able to burn those down and make sure that we were closing those out specifically before key tests as well.

Ellen Malloy

Key Features of the Nonconformance App

Fast, Filterable Defect Dashboards

- See open NCs by status, assignee, location, or last update

- Track conditions, disposition status, serial/lot numbers, and approvals

- Drill down by product, pedigree, location, or custom fields

Embedded Quality Oversight in Shop Floor and Inventory Workflows

- Detect defects during data collection and inventory operations

- Link NCs to work orders, supplier lots, or inspections

- Enforce “Must Resolve By” logic to apply trace-level constraints and actively contain defective parts

– Block active work or downstream operations until disposition is approved

– Prevent movement across inventory, or restrict to planned assemblies only

– Apply multiple constraints to control closeout operations, milestone activities, or WIP assemblies

– Automatically track and authorize movement through the NC workflow as part of disposition approval

– Gain full control and peace of mind with persistent containment at the trace level

Configurable, Rule-Based Dispositions

- Define disposition types (repair, rework, scrap, RTV) with linked rules

- Generate disposition operations tied to NC conditions

- Route and escalate approvals based on role, qualification, defect type, risk thresholds, or customer requirements

- Customize workflows, transitions, and required fields

Administrative Oversight and Granular Permissions

- Unlock or edit NCs with controlled admin privileges

- Override approvals with full audit logging

- Manage condition locks, redline releases, and proxy actions

- Configure trace and pedigree-based logic

End-to-End Traceability and Audit Readiness

- Log every action: what, where, when, and by whom

- Maintain a full timeline of discovery, analysis, and resolution

- Link NCs to CAPAs for root cause analysis, with automatic backflow of final cause data to all related NCs

- Eliminate manual updates—ensure consistent, accurate records across the NC network as soon as the CAPA is closed

- Export NC data to audit-ready PDFs

From Detection to Resolution

Defect or Event Triggered

Issue identified during inspection, data collection, or supplier receipt.

NC Record Created

Nonconformance logged with category, location, product, and automatically captured WIP traceability. “Must Resolve By” containment is applied automatically, with authorized control over downstream movement.

Disposition and Approval

Disposition type selected (e.g., rework, scrap, RTV) and routed for approval.

Root Cause and CAPA

Linked to CAPA or investigation if needed, with root cause documented.

Containment and Execution

Disposition sent to production or inventory with “Must Resolve By” control, which prevents escapes and avoid costly rework.

Resolution and Closure

Actions completed, approvals captured, and NC closed with audit trail.

Full Control with Configurable Features

Manufacturo’s NC system adapts to your quality processes and risk posture, supporting:

- Redline and release workflows

- Pedigree-controlled variance so engineers can focus on higher-level work, while reducing the burden on R&D hardware.

- Worry-free, fire & forget, “must Resolve By” logic for inventory and production control

- Custom fields for categories, sources, and classifications

- Configurable placeholders in NC condition and disposition notes to guide consistent documentation

- CAPA linkage for structured root cause analysis

- Quick follow-up actions for non-systemic defects using Action Boards

Administrative privileges include:

- Linking or unlinking NCs to CAPAs or operations regardless of status

- Disposition approval overrides

- Skipping redline approvals for minor redline releases

- Managing nonstandard traces

Why Choose Manufacturo’s Nonconformance App

Speed Up Quality Response

Identify, assign, and contain defects in real time

Reduce Recurrence

Link NCs to root cause and CAPA workflows

Maintain Audit Readiness

Capture all NC actions and approvals

Adapt to Your Workflows

Configure processes to your standards

Improve Team Coordination

Surface issues to the right teams promptly

Take a virtual tour

Learn more about Nonconformance Management

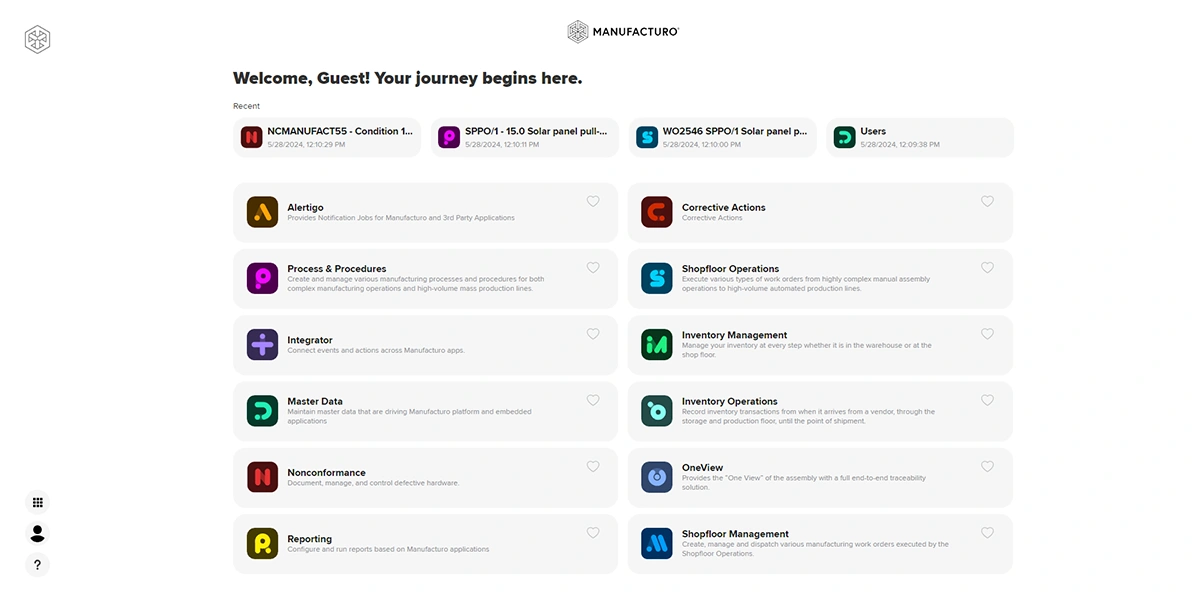

Check out our other applications

Seamlessly drive your production across all manufacturing models

Streamline your production processes and cut manufacturing costs

Monitor equipment availability, status, maintenance and calibration dates to eliminate inefficiencies

Ensure the right materials are available to meet production demands.

Control all inventory movements and contain defects at every step

Transforms pull-based replenishment into a connected, responsive system.

Effectively manage corrective, preventive, and containment actions and configure custom action types to improve your entire CAPA process

Centralize and control all documents within Manufacturo

Integrated, Transparent Action Tracking for the Shop Floor

Gain enhanced traceability to increase safety and compliance

Gain holistic visibility to predict, identify, and eliminate potential issues before they become critical blockers

Embed screens and customize attributes to improve data accuracy, streamline workflows, and increase productivity