Complete Manufacturing Traceability with One View

A Unified Solution for Quality Control, Compliance, and Process Optimization

In high-complexity manufacturing, limited visibility into as-builts in real time can lead to compliance risks, costly rework, and inefficiencies. To maintain quality, meet regulatory requirements, and minimize operational risks, manufacturers need complete traceability across every component and process. Without a robust solution, they face fragmented data, manual tracking, and a lack of real-time insights—making it harder to identify issues before they escalate.

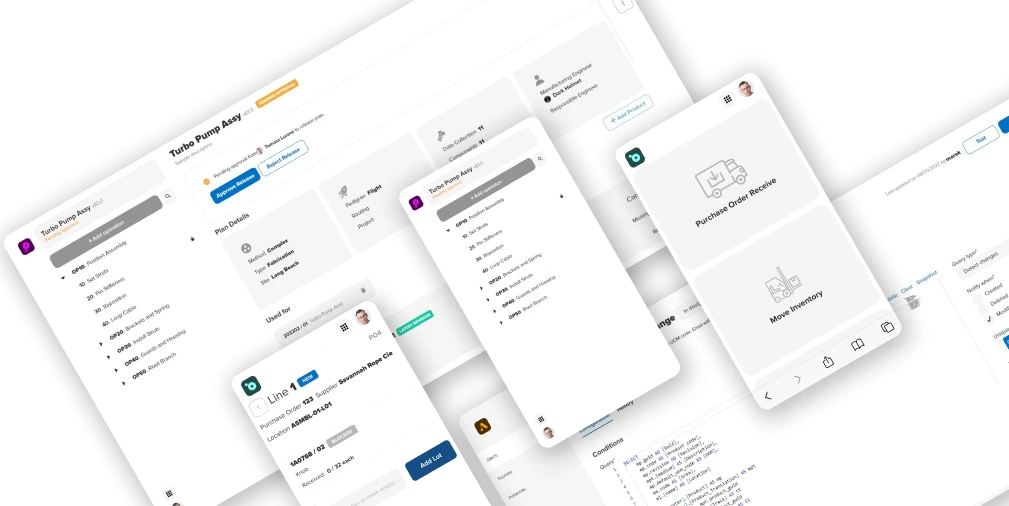

One View, an application within Manufacturo’s comprehensive manufacturing software suite, provides complete visibility and control over product completion—capturing the full as-built record and the detailed structure of every assembly, no matter how complex. Whether a product consists of just two layers or a deeply nested, 200-layer build, One View enables manufacturers to track each component with precision. By integrating traceability with quality management, inventory control, and shop-floor execution, One View helps identify deviations early, maintain compliance, and boost productivity. Purpose-built for high-complexity manufacturing, Manufacturo ensures full lifecycle traceability across all operations.

The Normalized Risks of Poor Traceability

Without a comprehensive traceability solution, manufacturers face serious risks. In industries like aerospace, defense, and energy, inadequate tracking can lead to regulatory noncompliance, costly recalls, and lasting reputational damage.

Too often, these risks are treated as the cost of doing business—but can your company truly afford them?

Without complete visibility, manufacturers face vulnerabilities such as:

- Difficulty identifying faulty components, leading to widespread recalls instead of targeted containment actions.

- Increased rework and scrap due to missing historical data on product changes.

- Inefficient root cause analysis, slowing down corrective and preventive actions.

- Compliance violations due to incomplete audit trails and missing documentation.

One View eliminates these risks by providing comprehensive traceability across the entire production process, from purchase orders to finished products.

Key Features of One View Traceability

Unified Component and Product Genealogy

- Track every part, subassembly, and final product in real-time.

- Consolidate key production, inventory, and quality data into a single digital thread.

- Gain full visibility into the as-built structure of assemblies and subassemblies.

- Compare as-built history to as-designed structures to detect deviations.

- Consolidate all critical events from Shopfloor Operations, Inventory Operations, and Nonconformance Management into a single source of truth.

- Track every action related to the build, including process plan revisions, purchase order receipts, and material movements.

- Ensure traceability across the entire lifecycle, from PO receipt and inventory transitions to installation and post-production inspections.

Multilevel and Multisite Traceability

- Control genealogy from top to bottom and across multiple manufacturing locations.

- Quickly identify serial and lot numbers for containment and compliance tracking.

- Monitor the percentage of completion at any stage of the assembly.

- View component installation status in real-time using color-coded indicators:

- Capture all deviations against an assembly or component, ensuring lifetime tracking.

- Track all actions down to the second, including who did what and when for complete accountability.

Seamless Integration with Manufacturo’s Software Suite

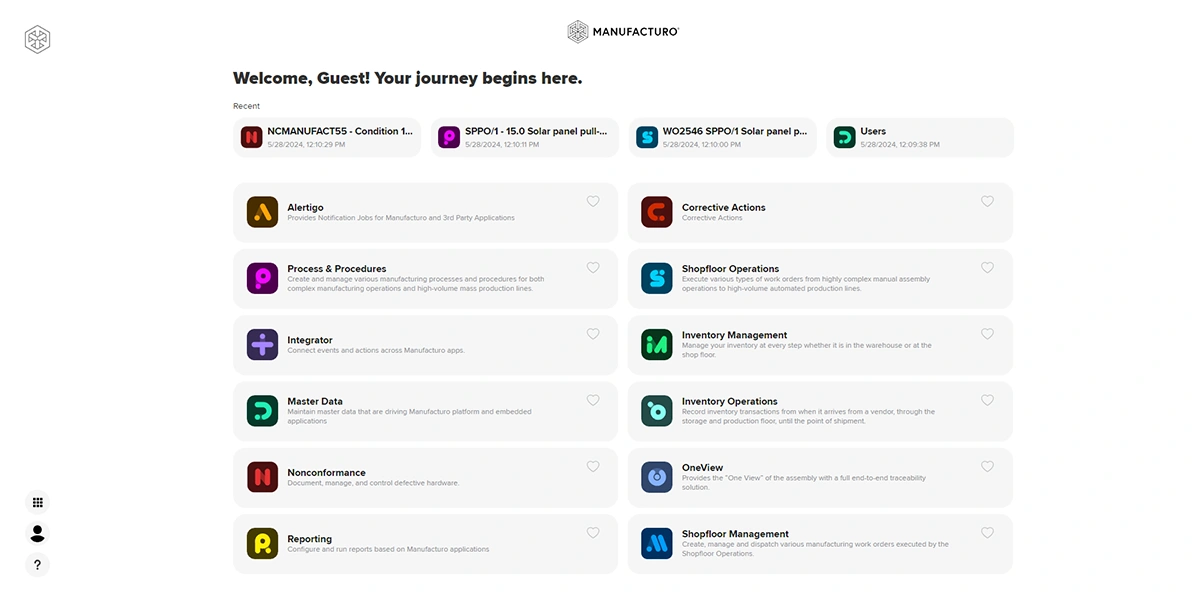

One View is part of Manufacturo’s broader manufacturing solution, which includes:

- Processes and Procedures – Ensuring standardized workflows and compliance.

- Shop Floor Operations – Managing work orders, real-time data collection, and execution.

- Traceability & Quality Management – Capturing, analyzing, and enforcing quality control across all stages.

- Nonconformance Management – Providing structured workflows for issue tracking and resolution.

- CAPA Management – identify, analyze and correct recurring issues.

Redlines and Engineering Change Notice (ECN) Management

- Understand every design modification with detailed change tracking.

- Compare as-designed vs. as-built genealogy to identify deviations.

- Improve process control by linking design changes to quality outcomes.

One View Genealogy Application

- Provides a holistic view of the entire as-built history of the hardware.

- Displays the latest build status and enables full comparison to the as-designed structure.

- Enables root-cause analysis and investigation into:

- What is in it? (Trace attributes: Serial, Lot, Pedigree, Project)

- What is remaining? (Pending installations for completion)

- Where is the problem? (Nonconformances, Disposition, Inspection Orders)

- Where is it used? (Work Orders, Locations, Reference Designators)

One View Genealogy Application

- Where is it used? (Work Orders, Locations, Reference Designators)

- Includes interactive genealogy tree structure with zoom, minimap, and navigation controls.

- Users can search by Serial No, Lot No, iTag, Work Order number, or Product Code to locate specific components.

- Clicking on a genealogy node provides detailed traceability insights and status updates.

- Tracks every person and action taken on a component down to the second.

- Provides forensic-level traceability, allowing manufacturers to rapidly analyze failures. For example, if a component fails in production, One View enables users to pinpoint the issue within hours.

Take a virtual tour to see our software in action

Find out how Manufacturo software can boost your efficiency, quality, and profitability

Visualizing One View Genealogy

The One View Genealogy application consolidates key data streams, including Process Planning, Shopfloor Operations, Inventory Management, and Non-Conformance Management, into a unified system for complete traceability. This enables manufacturers to:

- Align production history with design intent (as-designed, as-built, as-maintained).

- Compare planned vs. actual manufacturing data in real-time.

- Trace all inventory movements, supplier interactions, and nonconformance events from receipt to final assembly.

- Ensure complete accountability by tracking who performed what action and when—to the exact second.

- Quickly identify and contain issues using a centralized work instruction, inspection, and nonconformance management system for faster response times.

Nonconformance Tracking for Quality and Compliance

- Detects and documents nonconformance events from supplier notifications to production-side failures.

- Captures all deviations and inspection orders tied to assemblies and components.

- Ensures end-to-end documentation of corrective actions to prevent future issues.

Why Choose One View for Manufacturing Traceability?

Eliminate Data Fragmentation

Consolidate all traceability data into a single, real-time digital view.

Ensure Full Compliance

Maintain regulatory audit trails for ISO 9001, AS9100, and industry-specific standards.

Enhance Operational Visibility

Gain real-time insights into product genealogy and process deviations.

Reduce Recall Risks

Quickly identify and contain defective components before they escalate.

Streamline Manufacturing Oversight

Integrate seamlessly with nonconformance tracking, quality control, and inventory management.

Optimize Production Efficiency

Reduce waste, minimize rework, and accelerate speed to market.

Gain Full Control Over Your Operations

Achieve real-time visibility across your entire production process with One View.Learn About Our Full Suite of Integrated Applications

Seamlessly drive your production across all manufacturing models

Streamline your production processes and cut manufacturing costs

Monitor equipment availability, status, maintenance and calibration dates to eliminate inefficiencies

Ensure the right materials are available to meet production demands.

Control all inventory movements and contain defects at every step

Transforms pull-based replenishment into a connected, responsive system.

Eliminate nonconformance issues, mitigate nonconformity risk, and increase regulatory compliance

Effectively manage corrective, preventive, and containment actions and configure custom action types to improve your entire CAPA process

Centralize and control all documents within Manufacturo

Integrated, Transparent Action Tracking for the Shop Floor

Gain holistic visibility to predict, identify, and eliminate potential issues before they become critical blockers

Embed screens and customize attributes to improve data accuracy, streamline workflows, and increase productivity