Precision Process Planning for Complex Manufacturing

Build Consistency, Track Change, and Enforce Quality—All from One Central Engine

In high-complexity manufacturing, outdated or inconsistent instructions can lead to quality, compliance, and safety risks. Teams need clear, structured guidance that evolves with the product. Without it, documentation becomes fragmented, edits are error-prone, and engineering time is wasted.

Manufacturo’s Process and Procedures app eliminates that friction. From simple work instructions to complex flows with embedded quality checks, it serves as the single source of truth for how work gets done—ensuring teams follow the right sequence, collect the right data, and stay aligned with the latest approved process.

With Manufacturo, we can actually dive down to really good, precision process improvements based on good data—not assumptions or hypothesis…These work orders and this data specifically enable us to be very pinpointed with manufacturing process improvements that increase our speed.

Ellen Malloy

The Cost of Poorly Managed Procedures

When procedures are scattered across spreadsheets, shared drives, or outdated PDFs, manufacturers face:

- Increased rework and missed quality checkpoints due to unclear or outdated instructions

- Delays in production as teams seek clarification on redlines or revisions

- Audit failures stemming from undocumented changes and process gaps

- Misalignments between engineering intent and shop floor execution

Manufacturo’s Process and Procedures app brings clarity, control, and traceability to the core of your operations—helping ensure safe, compliant, and consistent execution every time.

Key Features of the Process and Procedures App

Master Procedures for All Manufacturing Methods

- Author detailed procedures for discrete, continuous, and hybrid production workflows

- Support multiple builds for the same part or variant without duplicating documentation

- Embed work instructions, required tools, data entry fields, quality gates, and reference documents

Dynamic mBOM Integration

- Map procedures directly to the manufacturing bill of materials

- Enable precise tracking of what gets installed, removed, or modified at each step

- Reduce errors by ensuring process and material usage stay in sync

Configurable Workflow and Export Capabilities

- Design branching process flows with split/merge paths

- Leverage role-based approvals and sign-offs at every stage

- Export procedures to PDF for offline reference, review, or regulatory submission

Advanced Data Collection and Validation

- Capture structured data in real-time with must-pass rules, control limits, and conditional logic

- Support complex calculations, tabular inputs, and dynamic display of fields based on context

- Guarantee process validation at every key decision point

Built for Flexibility and Speed

- Apply redlines safely and rapidly—without compromising compliance or clarity

- Maintain a living, version-controlled digital thread of process evolution

- Enable continuous improvement by propagating best practices quickly across procedures

Full Revision and Version Control

- Track all changes, from minor formatting updates to major flow revisions

- Compare versions and maintain full audit history across procedures, work orders, and traces

- Support active in-work revisions alongside released versions to manage change without disruption

- Identify where older Standard Operation revisions are applied across Work Orders

- Perform mass updates to apply the latest revision, with controlled permissions and status checks

Take a Virtual Tour to See Our Software in Action

Find out how Manufacturo software can boost your efficiency, quality, and profitability.

How Process Planning Powers Execution at Scale

Manufacturo’s Process and Procedures app is part of a broader production solution built to support high-tech, high-variation manufacturing environments. It synchronizes engineering, production, inventory, and quality workflows—ensuring consistency from planning to execution.

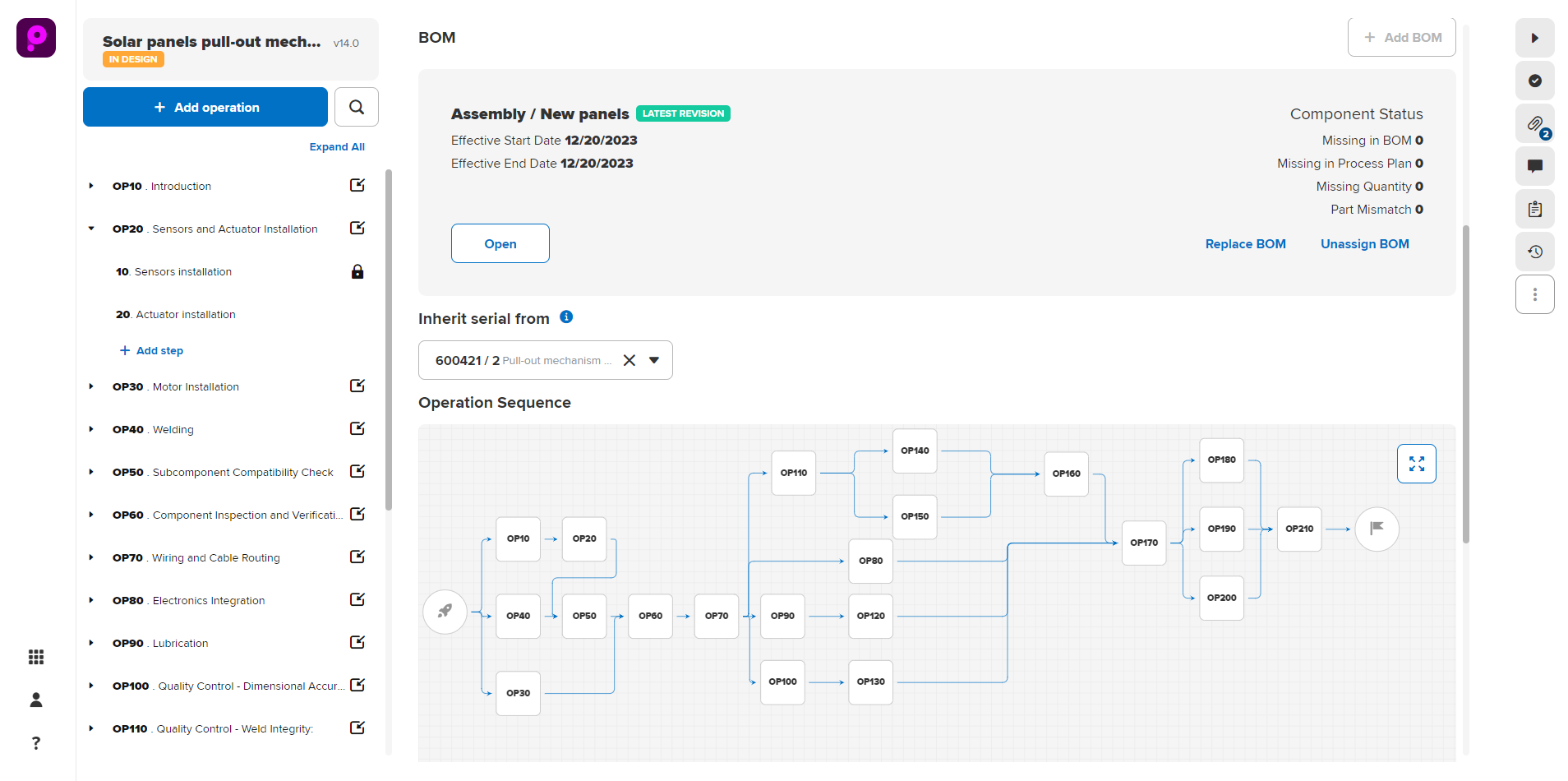

At the core is a powerful Process Planning engine that helps Manufacturing Engineers define, revise, and release procedures that flow directly into shop floor operations.

This diagram illustrates how process plans become live instructions, driving production, redline management, and traceability through every step of the build.

Process Planning and Shopfloor Operations Flow

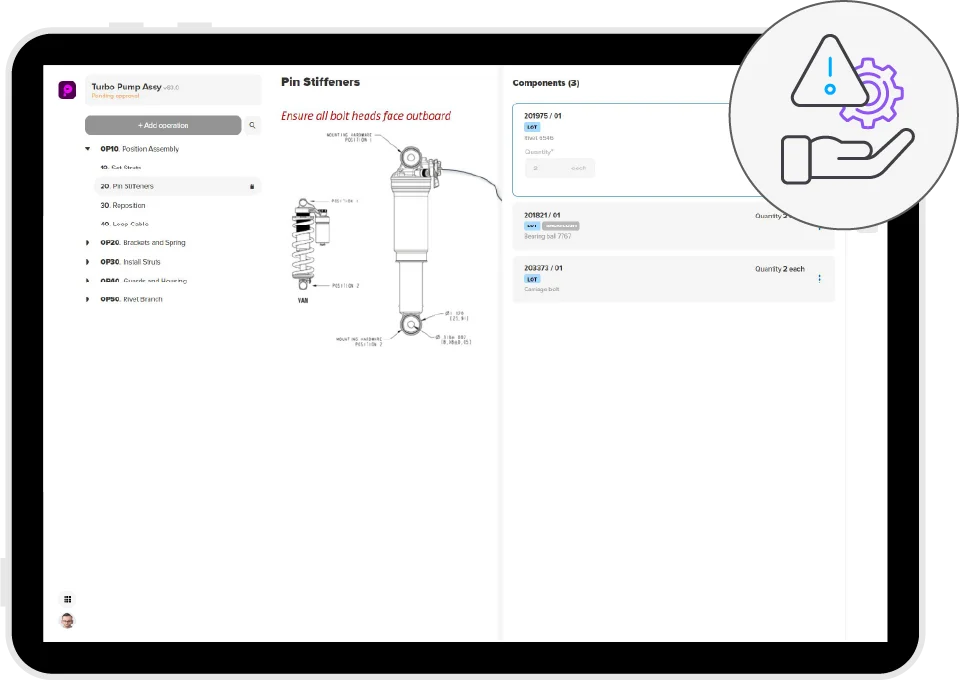

Real-Time Visibility Into Process Execution

As a part of Manufacturo’s suite of fully integrated applications, Process and Procedures ensures that the process plan isn’t just a document—it’s a live, enforceable, and traceable workflow:

- Connects directly to Shop Floor Operations for executing procedures in real time

- Ties into Inventory and Traceability to log what was done, with what, and by whom

- Links to Nonconformance and Quality Management to capture deviations against specific steps

- Whether your engineers are designing from scratch or improving an existing flow, every process is traceable, versioned, and connected to the broader context of your production.

Why Choose Manufacturo’s Process and Procedures App

Achieve Standardization at Scale

Create reusable, validated instructions across teams and products

Streamline Engineering Changes

Manage and apply revisions without confusion or risk

Ensure Audit Readiness

Maintain complete, contextual documentation of every build step

Enhance Operator Execution

Provide intuitive, structured, and validated procedures on the shop floor

Strengthen the Digital Thread

Link process instructions directly to execution, inspection, and inventory events

Learn About Our Full Suite of Integrated Applications

Streamline your production processes and cut manufacturing costs

Monitor equipment availability, status, maintenance and calibration dates to eliminate inefficiencies

Ensure the right materials are available to meet production demands.

Control all inventory movements and contain defects at every step

Transforms pull-based replenishment into a connected, responsive system.

Eliminate nonconformance issues, mitigate nonconformity risk, and increase regulatory compliance

Effectively manage corrective, preventive, and containment actions and configure custom action types to improve your entire CAPA process

Centralize and control all documents within Manufacturo

Integrated, Transparent Action Tracking for the Shop Floor

Gain enhanced traceability to increase safety and compliance

Gain holistic visibility to predict, identify, and eliminate potential issues before they become critical blockers

Embed screens and customize attributes to improve data accuracy, streamline workflows, and increase productivity