Our manufacturing software solution offers highly specialized manufacturing planning tools to effectively facilitate production management.

To learn more about each unique application and production process, visit manufacturing management software. The following are details on Process Planning that allows for developing a detailed production plan.

How Manufacturo software drives successful process planning

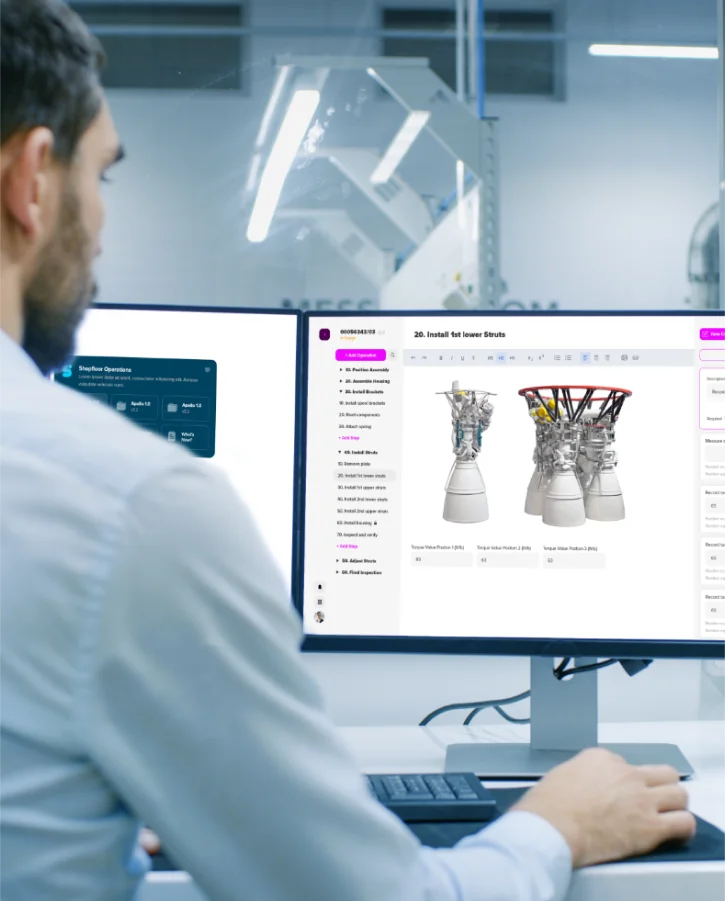

In any sector, complete process planning involves many intricate steps. In hi-tech emergent markets, selecting the right process planning application might be crucial for overall success. With its Process Planning feature, Manufacturo offers high-volume to complex production method in a single application, helping manufacturing engineers go through complex changes and keep track of all the history to ensure the production schedule is always on track.

Note:

Help manufacturing engineers go through complex process changes

Seamlessly integrate, collaborate and adapt to manufacturingneeds for enhanced change control and cost reductions

Process Planning enables manufacturers to:

Go paperless and effectively remove redundant paper from the shop floor.

Mirror the shop floor layout one-to-one to instantly see the progress across all manufacturing operations and quickly pinpoint the working area where issues occur, minimizing the risk of delays.

Manage mBOM to ensure effective change control and minimize the risk of accidental errors, unplanned disruptions, or unauthorized alterations.

Configure routing, pedigree rules, and order types to set additional requirements or restrictions for the process release, materials used for production, quality approvals, or any other necessary industry-specific steps.

Set step verification based on the defined skills and qualifications to ensure the qualified people approve process at each step of the process, leading to a quicker buyoff stage.

Add attachments, like images, tables, or hyperlinks to instructional videos, in a quick and easy way.

Organize order of operations or run some of them in parallel to better manage and optimize the manufacturing flow.

Define data collection fields, enter calculations and control limits, and create conditional rules that can also control the production flow and prevent quality escapes.

Import operations data from other, already existing production plans to faster meet production demand.

Define approval rights for process plan release, redlining, quality checks and control, or sign-offs.

Leverage the Revision capability to create and configure subsequent versions of products and production plans.

Capitalize on the Validate capability that automatically checks if the created process plan is free from mistakes.

Determine the standardized time necessary to complete each step of production.

Note:

Optimize your process plan

Process planning software is integral to achieving a paperless shop floor and is instrumental in streamlining production processes, maintaining production schedules, reducing manual procedures, enhancing resource management, and cutting production costs.

Manufacturo Process Planning enables all that. In its essence, Manufacturo is a single planning solution that allows for implementation of controlled process plans across all manufacturing models. These plans can then be accessed and adjusted by all engineers to drive integrated, collaborative, and production processes.

Future-proof production planning and control

Building a successful production process plan creates challenges regardless of the industry. The pace of technology innovation requires manufacturing operations to be digitalized. Whether through classic spreadsheets or advanced manufacturing planning software, manufacturers of all sizes seek solutions that will keep their production planning flow uninterrupted.

Manufacturers, especially those operating in a high-tech emergent industry, will benefit significantly from Manufacturo's features, and they will notice reduced time to market and quicker return on investment.

Effective change management

Multiple systems tend to complicate manufacturing operations rather than simplify them. Manufacturers that want to implement process changes end up spending more time and money on development and updates. Using a single, flexible solution helps achieve agility.

Seamless production flow

Feedback loop from shop floor to engineers will enable efficient, highly scalable production of complex technologies.

Advanced production planning features

Manufacturo Process Planning empowers organizations in complex industries where developing and implementing a production plan requires greater scrutiny and customization. Building a production planning method centered around Manufacturo's advanced planning features enables manufacturers to:

-

Ensure intuitive, powerful, and clean user experience (UX)

-

Capitalize on the web-based environment to work and perform planning activities from any screen, as long as on the network

-

Use single platform to scale from complex manual assembly to high-volume automated mass manufacturing

-

Adjust work orders to correct engineering change orders, removing critical defects early and staying on top of material requirements

-

Support serial and batch tracking for all parts to combine traceability with efficiency

-

Gain complete real-time visibility and traceability across fragmented manufacturing processes to ensure production efficiency

Unique features that accelerate manufacturing planning

Process Planning’s dynamic integrated process plans align design with manufacturing across operations from fabrication to refurbishment to fuel-efficient manufacturing processes. Manufacturo's process planning application drives connected, collaborative plans for manufacturing by:

Enabling planners and engineers to instantly release and adjust plans, drawing on live shop floor feedback and real-time data to reflect manufacturing needs and fuel concurrent design and manufacturing.

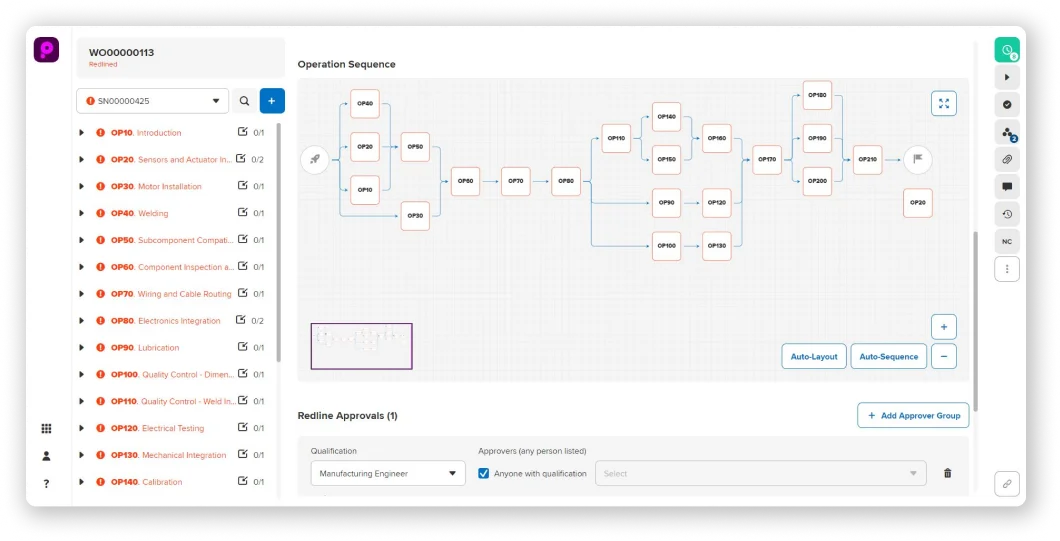

Adjusting plans to meet quality requirements using work orders that can be redlined on-site in real time, fixing nonconforming components.

Fostering cohesive, collaborative manufacturing through one common planning solution for end-to-end processes from fabrication to preventative maintenance.

Note:

Benefit from redlining, increased traceability, and improved change control

Manufacturers carefully selecting and deciding on process planning software that best meets their needs gain greater visibility, increased traceability, and improved change control. Manufacturo's Process Planning provides numerous benefits to organizations in the complex manufacturing industry.

Process Planning:

-

Increases visibility and traceability of all parts across production lines, by enabling manufacturers to efficiently track parts individually or in batches at any stage

-

Enables holistic manufacturing through integrated planning and data collection across all manufacturing models and operations

-

Enables manufacturers to seamlessly adapt routing, pedigrees or different types of work orders within a single platform

-

Drives dynamic development, continually optimized with employee feedback and redlining at every stage of manufacturing

-

Offers accessible, configurable integrated plans encompassing end-to-end manufacturing that connect design with engineering and smoothly adjusts plans to operational realities

Redlining

Redlining is an indispensable capability in complex manufacturing. From aerospace to automotive—and every industry segment in between—successfully navigating the dynamic fast-paced environment requires a software solution with the intuitive toolkit to thread the needle between speed and precision.

Manufacturo’s enhanced redlining functionality gives engineers the ability to quickly and easily make clear changes to work orders in near real time.

Engineers can also markup work orders to define disposition operations, ensuring that nonconforming parts are handled correctly, and corrective actions are properly documented.

Full traceability ensures that all stakeholders can view the changes at any time. To maximize efficiency, batch redlining functionality can be utilized. All changes are seamlessly reproduced to all traces in the batch, which enables timely updates across multiple documents, increasing consistency and reducing errors.

Redlining also provides the following benefits:

- Enhances communication, collaboration, and situational awareness

- Ensures that deviations are corrected within the bounds of quality requirements

- Maintain safety and compliance standards

Help manufacturing engineers go through complex process changes

Seamlessly integrate, collaborate and adapt to manufacturingneeds for enhanced change control and cost reductions