To stay ahead of the competition, contemporary manufacturers must leverage advanced shop floor software solutions. Such tools are designed to increase productivity with real-time operational visibility, enhanced resource utilization, and coordinated production processes. A high quality solution will also track key performance indicators (KPIs), while integrating fluidly with ERP and WMS systems.

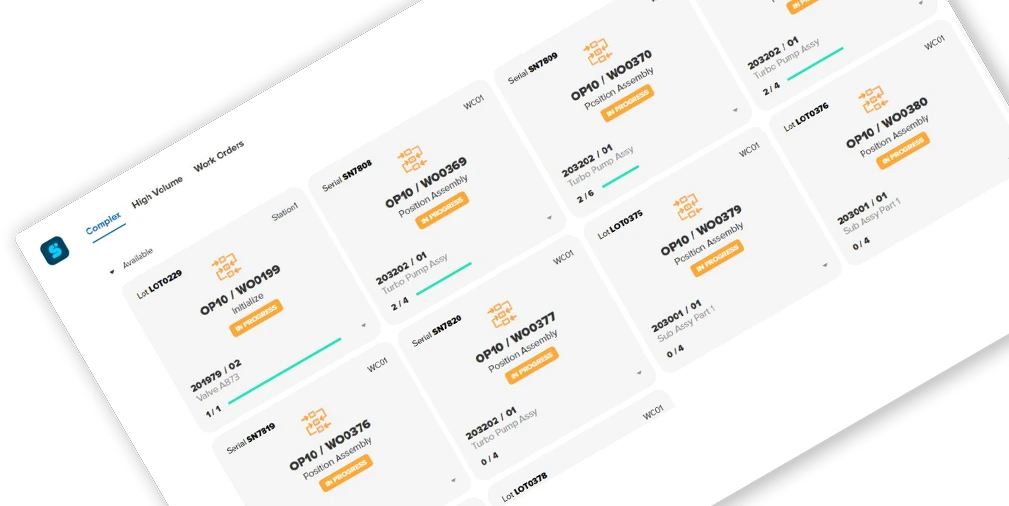

Whether in high-volume assembly lines or high-complexity shop floor environments, implementing shop floor software allows businesses to streamline operations, minimize waste, and improve product quality.

What is Shop Floor Control Software?

Shop floor control software is designed specifically for operators to optimize production processes, reduce downtime, and improve overall equipment utilization. Shop floor management software provides operational insights into production workflows, helping managers monitor progress, identify bottlenecks, and ensure timely decision-making.

By integrating with existing systems like Enterprise Resource Planning (ERP) and Warehouse Management Systems (WMS), shop floor control centralizes data, making it accessible to all stakeholders. These integrations improve resource allocation and alignment of operational schedules with demand, ensuring smooth manufacturing operations.

Key Benefits of Shop Floor Control

Real-Time Visibility & Oversight

A well-managed work floor requires immediate visibility into production data. Shop floor software delivers real-time dashboards with analytics on cycle times, equipment utilization, and labor productivity.

By eliminating manual redundancies and supporting digital factory initiatives, shop floor software creates a paperless production environment, improving operational efficiency and compliance, and allowing operators to hit production goals.

Operational Schedules & Resource Utilization

Maintaining an exacting schedule is crucial for production efficiency. Shop floor software aligns scheduling with real-time production demands, allowing manufacturers to allocate resources effectively.

- Dynamic Scheduling Adjustments: Adapt manufacturing schedules based on machine availability and order priority.

- Inventory & Stock Control: Prevent shortages and maximize resource availability by integrating with shop floor control features like real-time material tracking.

- Automated Workflows: Reduce human error and ensure seamless shop floor transitions.

This operations control strategy not only improves efficiency but also enhances customer satisfaction by enabling on-time delivery and consistent product quality.

Shop Floor Operator Empowerment & Accountability

Shop floor operators are at the heart of workshop floor, and the right software ensures they have the tools for success, such as:

- Assigning and tracking tasks with real-time dashboards.

- Job performance and efficiency metrics.

- Allowing shop floor workers to add human-context insights, improving production data accuracy.

With digitized solutions, businesses can ensure accountability and facilitate seamless communication across production.

Data-Driven Decision-Making

Comprehensive data collection and analysis is a must for manufacturers. A robust shop floor software system will track KPIs, including:

- Cycle times and machine utilization to maximize output.

- Labor productivity to evaluate employee efficiency.

- Defect analysis for continuous quality improvements.

By automating KPI tracking, the software provides actionable insights, allowing manufacturers to benchmark performance against historical data and industry standards.

Job Setup, Changeover Tracking, and Downtime Reduction

Reducing job setup and changeover times enhances manufacturing performance. Shop floor software enables:

- Standardized setup benchmarks for process improvements.

- Time tracking for each job changeover to minimize downtime.

- Streamlining transition periods in operations.

Unplanned downtime can significantly disrupt the manufacturing process. Production monitoring features can categorize downtime reasons and enable rapid issue resolution for crucial analysis and preventative measures.

- Downtime Reporting: Identify recurring machine failures or other issues on the shop floor.

- Predictive Maintenance: Address potential issues before they impact production.

- Instant Notifications: Alert operators to delays to coordinate swift resolution.

With real-time alerts for production roadblocks or quality issues, shop floor managers can make informed decisions and take immediate action to maintain efficiency and meet production requirements.

Alerts & Notification Systems

Shop floor software provides instant alerts to notify teams of job delays or deviations from expected benchmarks. These real-time updates enhance shop floor control by:

- Preventing production bottlenecks with automated job tracking.

- Providing real-time status updates for maintenance and job progress.

- Escalating critical alerts to ensure minimal disruption.

This level of automation empowers managers to be proactive rather than reactive.

Standard vs. High-Complexity Manufacturing

Unique Challenges in High-Complexity Manufacturing

Certain industries - such as aerospace, medical devices, and defense - require specialized solutions to manage intricate manufacturing processes. Key requirements include:

- Advanced Scheduling Systems: Accommodating multi-stage workflows and precise tolerances.

- Stringent Quality Control: Meeting regulatory standards (e.g., ISO, FDA, AS9100).

- Comprehensive Data Integration: Connecting MES, PLM, and ERP.

Specialized Shop Floor Software Solutions

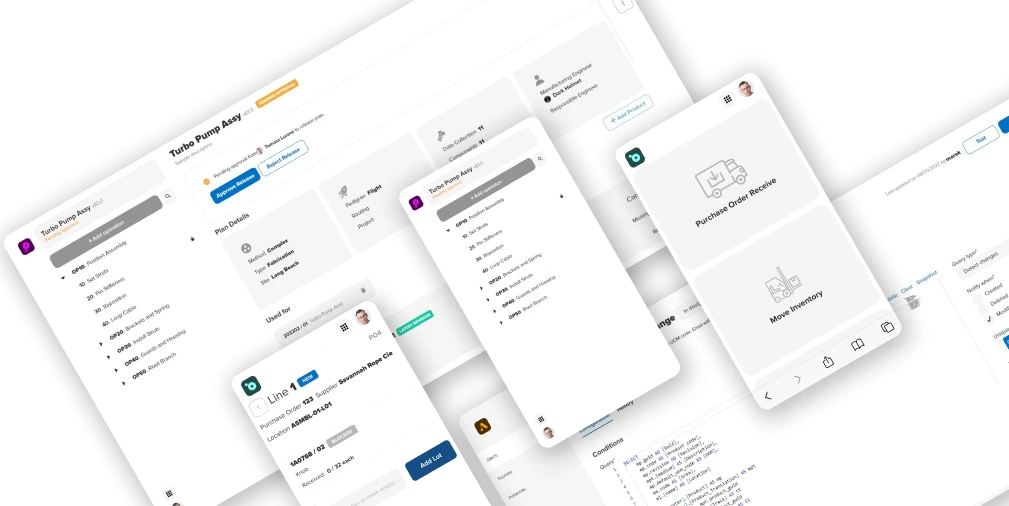

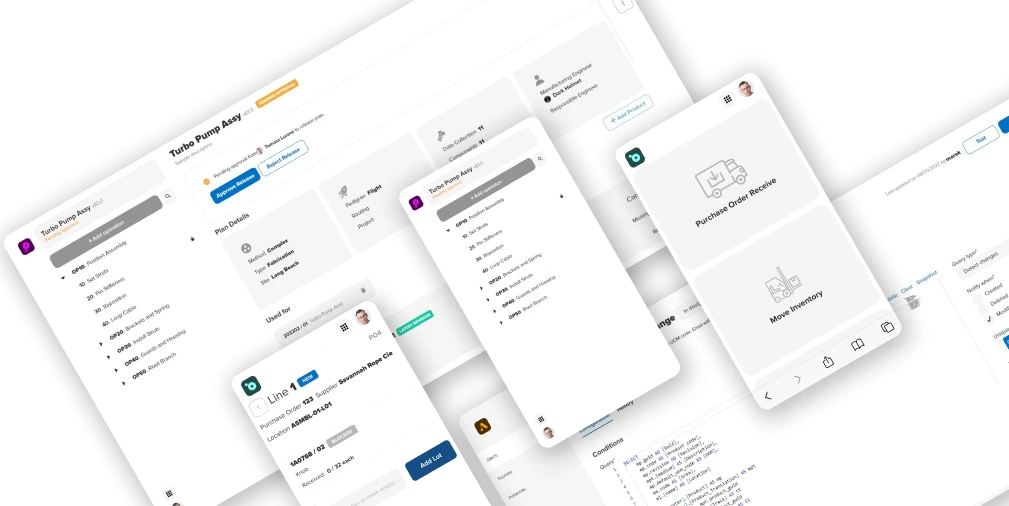

Software solutions like Manufacturo are designed to adapt to evolving production needs. Features include:

- Modular & Scalable Architecture: Supporting businesses as they grow.

- Integrated Communications: Connecting the shop floor directly with inspectors and engineers for calls and actions.

- Crystal Clear Instructions and Workflows: Easy to understand work order information and work instructions so technicians can quickly and accurately perform tasks.

Selecting the Right Shop Floor Software for Your Business

To maximize production processes, manufacturers should consider:

- Production Complexity: Does the system support simple and complex shop floor workflows?

- Integration Capabilities: Can it connect with ERP, WMS, and automation tools?

- Scalability: Will it grow with business needs?

- Regulatory Compliance: Does it maintain clear audit trails and digital record-keeping?

Investing in the right software ensures long-term efficiency, quality, and operational success.

Common Key Features

Most digital solutions share several core functionalities essential for shop floor efficiency:

- Real-Time Monitoring – Live insights into shop floor status, machine utilization, and inventory levels.

- Production Scheduling – Planning and adjusting production timelines to optimize resources and meet demand.

- Inventory Control – Tracking raw materials and finished goods, ensuring optimal stock levels.

- Task Management – Assigning and tracking tasks to enhance workforce productivity.

- Reporting and Analytics – Generating data-driven reports on key performance indicators (KPIs) such as Overall Equipment Effectiveness (OEE), production costs, defect rates, and other metrics to track progress.

- System Integration – Connecting seamlessly with ERP, WMS, and accounting platforms to unify data and improve decision-making.

Unique Features

While most shop floor software solutions offer standard shop floor control capabilities, some include additional functionalities to address specific operational needs:

- Mobile Accessibility – Remote access to shop floor operations via mobile devices.

- Customizable Dashboards – Tailoring shop floor control data displays to match roles and responsibilities.

- Predictive Maintenance – Using real-time data to anticipate and prevent machine failures.

- Cloud-Based Integration – Enabling flexible oversight through web-based platforms.

- Visual Scheduling Tools – Enhancing planning and production tracking with user-friendly interfaces.

- Automated Quality Control – Integrating statistical process controls and compliance management tools to meet industry standards and address quality issues.

Introduce and record product changes across production

Comparative Analysis of Software Solutions

A comparative analysis of various shop floor control systems highlights areas of consensus and points of differentiation:

Areas of Consensus

- Real-Time Data Access – Every system prioritizes live monitoring and analytics for improved shop floor control.

- Seamless Integration – Most solutions connect with ERP, CRM, and financial software to provide unified data access.

- User-Friendly Interfaces – Accessibility and ease of use remain crucial for quick adoption and effective shop floor management.

Key Differences

- Integration Capabilities – Some solutions are fully integrated into operational management software, while others require APIs connectivity.

- Industry-Specific Features – Certain platforms cater to small operators, while others focus on large enterprises with complex manufacturing processes.

- Scalability – Not all shop floor control systems are dynamically built for scaling.

Comparison of Shop Floor Management Software: Manufacturo vs. Other Leading Solutions

Manufacturers seeking shop floor control software have numerous options to enhance real-time monitoring, inventory tracking, and process automation. Below is a comparative analysis of Manufacturo alongside other leading providers of traditional and niche MES systems.

Real-Time Monitoring & Data-Driven Insights

- Best for Live Production Tracking: MachineMetrics and Prodio offer real-time dashboards and IoT-powered machine monitoring for instant insights.

- Manufacturo’s Advantage: Enables remote real-time monitoring across the entire shop floor, integrating inline validation, nonconformance tracking, and data-driven instructions.

Change Management & Engineering Integration

- Best for Change Management: Manufacturo excels in engineering change integration, enabling redlining by individual serials, ensuring modifications are seamlessly incorporated into active work orders without halting production.

- Standard Solutions: Katana and MRPeasy provide efficient drag-and-drop production planning, but lack robust change management workflows needed in high-complexity industries like aerospace and medical devices.

Production Scheduling & Planning

- Best for Adaptive Workflows: Siemens Opcenter Execution integrates shop floor scheduling within an MES system, ideal for complex production planning.

- Manufacturo’s Advantage: AI-powered workflow automation adjusts assembly lines based on live production data, reducing bottlenecks and optimizing resource allocation in high-mix, low-volume manufacturing.

Inventory & Resource Management

- Best for Small Manufacturers: Katana and MRPeasy excel in real-time stock tracking and automated reordering for small-to-mid-sized businesses.

- Manufacturo’s Advantage: Offers full inventory integration, automating kitting order placements, lineside inventory tracking, and consumables control—ensuring real-time synchronization between inventory and production.

Compliance & Quality Control

- Best for Regulatory Compliance: DELMIAWorks and Siemens offer strong ERP-integrated compliance tracking.

- Manufacturo’s Advantage: Delivers automated compliance mapping, live production data validation, and robust audit trail tracking, aligning with ISO, FDA 21 CFR Part 11, and AS9100 standards.

Integration Capabilities

- Best for ERP & MES Connectivity: DELMIAWorks integrates directly into ERP, while MachineMetrics and Quickbase support custom API integrations.

- Manufacturo’s Advantage: Manufacturo's Shop Floor Operations is fully integrated into its MES, QMS, SCM and nonconformance and CAPA projects for seamless enterprise-wide visibility.

Scalability & Industry Focus

- Best for Small & Medium Businesses: Katana, MRPeasy, and Prodio cater to light manufacturing and growing businesses.

- Manufacturo’s Advantage: Designed for high-tech, R&D-driven industries of all sizes - including aerospace, defense, energy, new space, and drones - while supporting multi-site scalability, global compliance tracking, and adaptive assembly.

Configurable features that optimize shop floor operations

Use Cases and Industry Applications

Shop floor control solutions are widely adopted, including in the following high-complexity industries:

An aircraft manufacturer integrates shop floor software to monitor composite material usage, optimize multi-stage assembly workflows, and ensure FAA-compliant real-time quality inspections for high-precision aircraft production.

A military equipment manufacturer uses shop floor software to ensure real-time tracking of precision machining, compliance with ITAR regulations, and seamless coordination between production and quality assurance teams to meet strict defense contract requirements.

A surgical implant producer employs the software to maintain strict FDA and ISO 13485 compliance, monitor sterile manufacturing environments, and manage production scheduling for high-precision medical devices.

An advanced additive manufacturing facility leverages shop floor software to automate print queue scheduling, monitor additive manufacturing material usage, and track post-processing workflows for high-detail, custom-printed components in medical and automotive applications.

A private space launch provider uses shop floor software to streamline rocket production, track propulsion system assembly in real time, and optimize supply chain logistics to meet tight launch schedules and mission deadlines.

Key Insights and Emerging Trends

Several trends are shaping the future of shop floor control:

- Cloud-Based Solutions – Adoption of cloud-based shop floor software is rising due to its flexibility and scalability.

- Mobile Accessibility – Increased demand for mobile-friendly shop floor control interfaces.

- AI and Automation – Predictive analytics and automated workflows are becoming standard for advanced shop floor management.

- Customization and Modular Design – Many businesses seek shop floor control software that adapts to their specific needs.

- Real-Time Alerts and Notifications – Instant alerts enable rapid responses to shop floor issues, reducing downtime and increasing throughput.

At a Glance: How Shop Floor Control Software Boosts Productivity

Using shop floor applications brings numerous big-picture advantages to manufacturing businesses in terms of boosting productivity, such as:

- Increased Efficiency – Automates repetitive tasks, reduces errors, and improves resource allocation.

- Enhanced Visibility – Provides a complete overview of shop floor activities for data-driven decision-making.

- Improved Communication – Ensures seamless coordination between teams and departments.

- Cost Reduction – Minimizes waste, reduces downtime, and lowers operational expenses.

- Scalability – Supports both small operations and large-scale shop floor environments

Conclusion

Effective shop floor control is essential for modern manufacturers looking to optimize production processes, minimize waste, and improve overall efficiency. By leveraging shop floor software, businesses can reap data insights, automate workflows, and enhance operational visibility.

Whether operating in standard production settings or high-complexity industries, shop floor software provides the tools needed for competitiveness and long-term growth. By integrating cutting-edge shop floor control solutions, businesses can optimize production processes and take their shop floor performance to the next level.

Full Visibility. Next-Level Change Management. Slashed Costs.