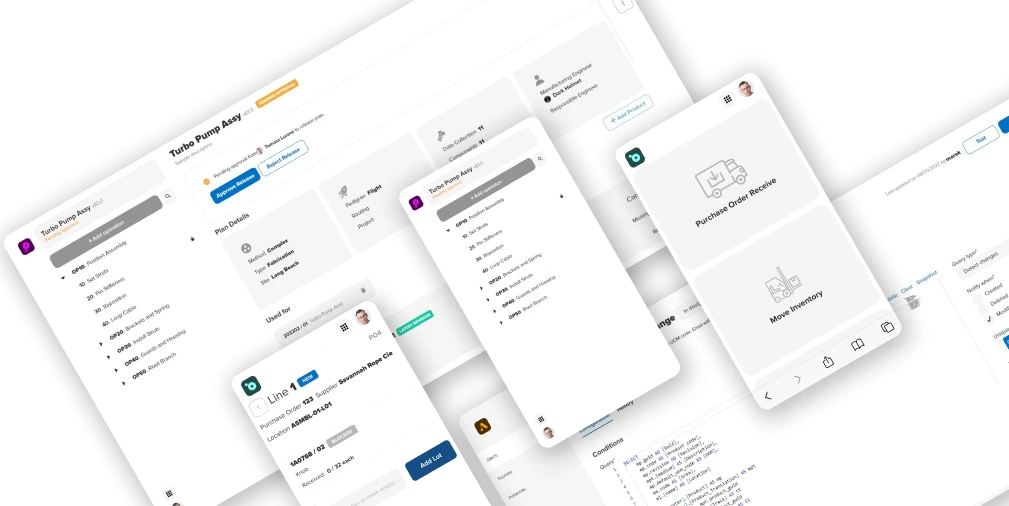

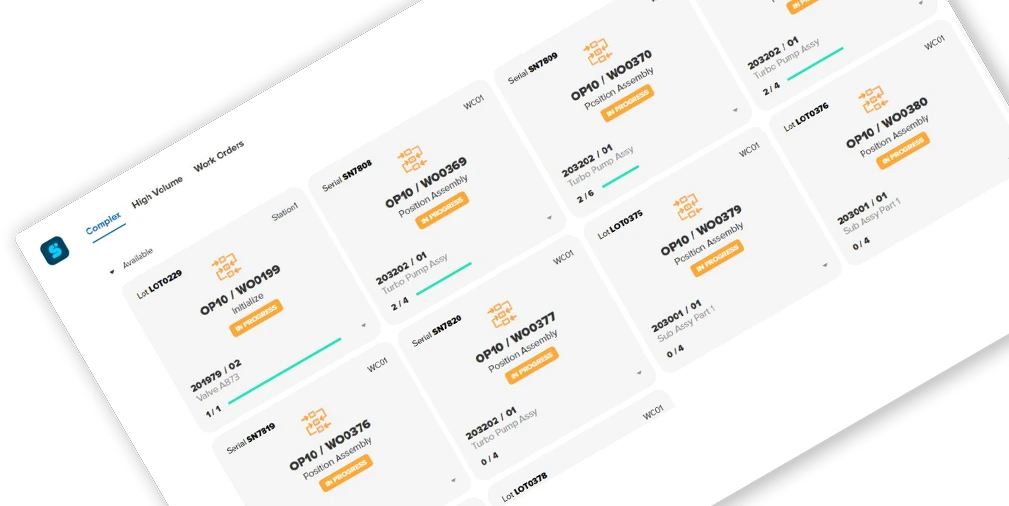

To stay ahead of the competition, contemporary manufacturers must leverage advanced shop floor software solutions. Such tools are designed to increase productivity with real-time operational visibility, enhanced resource utilization, and coordinated production processes. A high quality solution will also track key performance indicators (KPIs), while integrating fluidly with ERP and WMS systems.

Whether in high-volume assembly lines or high-complexity shop floor environments, implementing shop floor software allows businesses to streamline operations, minimize waste, and improve product quality.