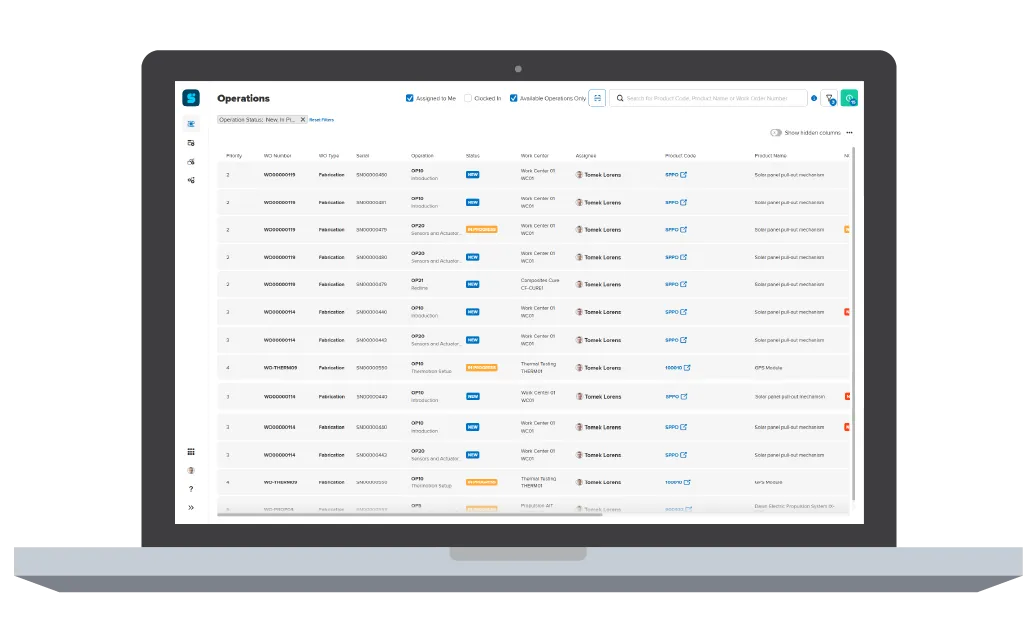

Shopfloor Operations

Smarter Execution. Connected Production.

From build to inspection, the Shopfloor Operations App empowers your teams with everything they need to execute work orders efficiently and accurately—fully integrated with quality management, inventory, traceability, and planning. Every action is documented, every step is auditable, and every part is accounted for.

Manufacturo brings all your shop floor activities into a centralized digital workspace—eliminating paperwork, reducing delays, and enabling a more responsive, quality-driven manufacturing process.

Going paperless on the shopfloor is a huge advantage. Having everything digital, you can attach almost any kind of control function to summarize it…So I have 100% traceability of who was working on which workstation, building what assembly under what temperature, condition, and humidity. So, it’s amazing. You can see everything and just with a click, you can combine these lines.

Peter Dachs

Why Shop Floor Operations Matters

Traditional MES systems often slow things down—locking teams into rigid workflows and siloed systems. Manufacturo breaks through those constraints, enabling real-time execution and complete visibility across your production floor.

- Execute work orders with clear, step-by-step guidance and built-in validations

- Capture inspections, tests, and user actions as they happen—no delays, no gaps

- Manage redlines, rework, and alternate parts with full traceability

- Stay aligned with inventory, nonconformance, and production planning in real time

- Move faster, document as you go, and maintain always audit-ready records

Key Capabilities

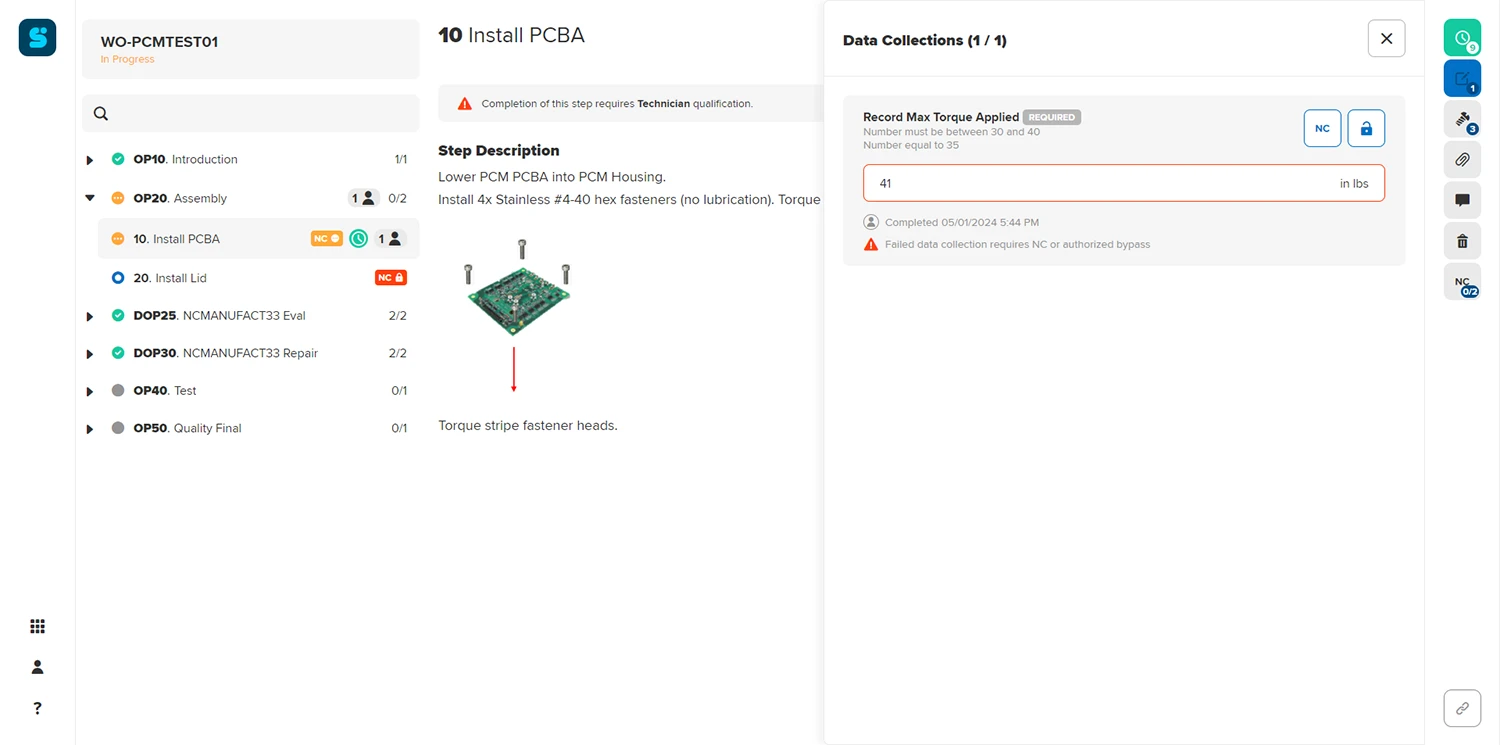

Work Order Execution

Step-by-step guidance with version-controlled procedures.

Inspection & Data Capture

Log visual, dimensional, or process-based inspections.

Rework & Redlines

Apply changes on the fly with full documentation

Traceability

Track parts, materials, buy-offs, and actions across the lifecycle

Inventory Sync

Ensure real-time availability and component accuracy

Nonconformance Triggers

Flag and contain issues immediately

User-Friendly UI

Role-based access, quick scanning, and intuitive layout

Designed for Your Production Team

Whether you're assembling complex systems or printing precision parts, the Shopfloor Operations App supports every stakeholder on the floor:

Technicians

Follow defined steps, scan barcodes, log work in real time, report NCs.

Use Case: Assemble a satellite propulsion module using a redlined procedure with alternate parts, ensuring traceability through every install step.

Production Coordinators

Prioritize and monitor operations across shifts

Use Case: Reprioritize delayed work orders across battery module assembly lines to keep clean energy builds on trac

Quality Inspectors

Record inspections, trigger NCs, and manage checkpoints

Use Case: Perform a batch-level dimensional inspection on 3D-printed turbine blades and log a single nonconformance report for the affected tray

Engineers

Push redline updates and respond to floor-level feedback instantly

Use Case: Push urgent procedural updates to a defense aircraft actuator build after a supplier revision, ensuring floor teams have the latest specs.

Learn How Shop Floor Execution Should Work

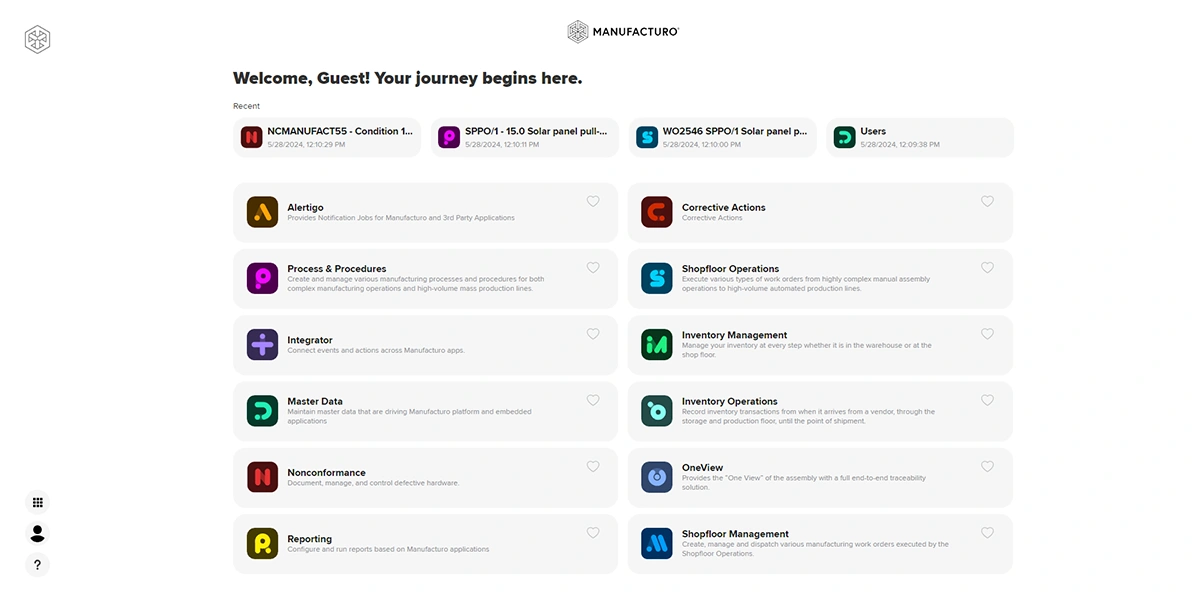

Discover how leading manufacturers are using Shopfloor Operations to reduce risk, improve traceability, and speed up production.Integrated for End-to-End Visibility

Shopfloor Operations is not a standalone tool—it’s fully embedded into the Manufacturo ecosystem to create a seamless, traceable production flow.

Use Case: A technician scans a serialized part before use. Manufacturo instantly verifies that the part has the correct product code, revision, and pedigree, and that it isn’t blocked due to missing inspections or open nonconformances. Only then does the system update inventory, log the part to the traceability record, and trigger the next procedure step—ensuring that builds proceed with the right parts and full confidence.

This level of connectivity helps reduce process risk, accelerate production timelines, and ensure you always have a clear picture of what’s happening on your floor.

Smarter Batching for Additive & High-Mix Operations

Legacy MES tools make grouped execution painful—one click at a time. With Manufacturo, batch execution transforms how you manage multi-part builds:

- Execute multiple operations together from a single screen

- Apply redline updates across the batch in one step

- Submit nonconformance reports for all impacted units at once

Additive Manufacturing Use Cases

- Print Tray Management – Confirm builds across multiple serials

- Post-Processing – Run heat treat or cleaning steps as a batch

- Batch Inspections – Log results for trays of printed components

- Design Changes – Apply redlines across all affected parts simultaneously

Batching simplifies documentation, reduces errors, saves time on clicking through Work Orders one-by-one, and enables higher throughput in complex, low-volume production environments.

The Shopfloor Operations App Benefits

By combining real-time execution, deep integration, and streamlined batching, the Shopfloor Operations App helps manufacturers:

Increase speed to market

Improve first-pass yield

Eliminate manual documentation errors

Maintain continuous audit readiness

Reduce production risks and delays

Take a virtual tour

Learn more about Shopfloor Control

Check out our other applications

Seamlessly drive your production across all manufacturing models

Monitor equipment availability, status, maintenance and calibration dates to eliminate inefficiencies

Ensure the right materials are available to meet production demands.

Control all inventory movements and contain defects at every step

Transforms pull-based replenishment into a connected, responsive system.

Eliminate nonconformance issues, mitigate nonconformity risk, and increase regulatory compliance

Effectively manage corrective, preventive, and containment actions and configure custom action types to improve your entire CAPA process

Centralize and control all documents within Manufacturo

Integrated, Transparent Action Tracking for the Shop Floor

Gain enhanced traceability to increase safety and compliance

Gain holistic visibility to predict, identify, and eliminate potential issues before they become critical blockers

Embed screens and customize attributes to improve data accuracy, streamline workflows, and increase productivity