Many agile manufacturing enterprise systems (MES) come with a major drawback: governance that is too loose. The problems aren’t always apparent at first. They become visible when production ramps and teams test the system with critical everyday inquires like:

- Which units are affected by this nonconformance?

- What was installed on this assembly at this station on this date?

- Which serials shipped with this lot or revision?

Too often the answer is, “We don’t know yet. This will take some digging.”

This answer is a red flag that the MES is under governed in its architecture: parts, processes, quality checks, and data are not tightly tied together or enforced by the system.

When that structure is missing, operations slow down and quality-related risks increase.

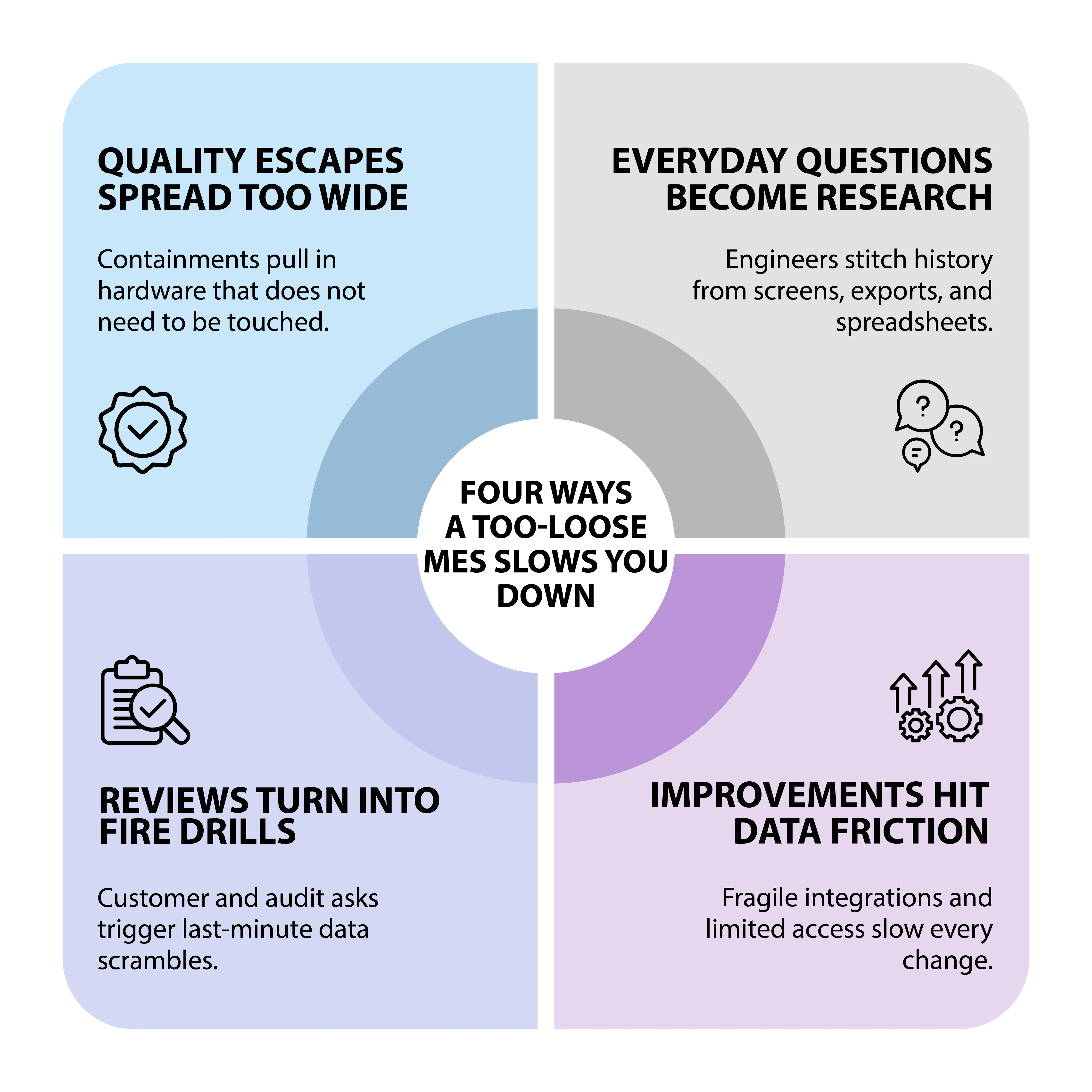

Here are four common ways too-loose MES problems show up in day-to-day operations, and how they drag productivity.

1. Quality escapes turn into broad, messy cleanups

When BOM, routing, and kitting aren’t tightly linked, the MES can’t show exactly which units are at risk. Instead, teams piece together partial signals from:

- Work orders

- Kitting events

- Test records

To stay safe, containments widen - pulling in hardware that may not need to be touched and reworking assemblies “just in case.”

The problem: Containments become larger and more disruptive than necessary, and doubt still remains about what might have slipped through.

The answer: A governed model maps each component to a specific operation and updates the as-built at install. That keeps containments tight, targeted, and defensible.

2. Everyday questions become research projects

Loose MES structure turns routine questions into detective work:

- What was installed here on this date?

- Which material is actually at the line?

- Is this step really ready to move?

Engineers bounce between screens, exports, and spreadsheets to reconstruct history.

A common driver is the kitting-to-install gap. Many MES platforms treat “kitted” as “installed,” but real production doesn’t work that cleanly. In practice:

- Parts sit line-side after kitting

- Inventory is decremented at kitting, not install

- As-built records lag physical reality

The result is a system that can’t reliably answer what was actually installed where and when, so investigations stretch longer and containments stay broader than they need to be.

The problem: Everyday questions burn engineering time because the system doesn’t reflect what actually happened on the floor.

The answer: A structured MES separates kitting, line-side presence, and install, and updates inventory and as-built at the point of use. That alignment is what makes traceability fast, containments precise, and day-to-day decisions trustworthy.

3. Audit and customer questions feel heavier than they should

Audits may be rare, but customer reviews, launch readiness checks, and internal safety inspections are constant. When teams ask the MES to show:

- Which serials used a specific lot or revision

- What was installed at a station during a defined time window

…it should answer directly. Under governed systems can’t, so teams rely on one-off queries, spreadsheets, and last-minute slides outside the MES.

The problem: Reviews become fire drills because live traceability isn’t reliable.

The answer: A structured, revision-aware model makes audit readiness the default. The system answers customer and compliance questions without side projects.

4. Data and integration friction slows improvements

The same loose structure also limits data and integrations. As factories grow, they need to:

- Connect more systems (planning, test, ERP, analytics)

- Ask deeper questions of historical data

- Extend models for new programs or regulatory needs

Under governed MES platforms make this hard, so:

- Integrations stay fragile and vendor-dependent

- Raw data access is limited

- Model changes feel heavy and slow

The problem: Improvements stall because operational data isn’t structured for internal use.

The answer: A more structured, open architecture lets teams use operational data directly, not pry it out of the MES.

How Manufacturo turns MES data into an engine for productivity

Manufacturo is designed so operational data is trusted, accessible, and reusable. Parts are tied to operations, as-built updates at install, and API-first interfaces make integrations and analysis straightforward.

Side-by-side comparison

|

Area |

Under-governed MES |

With Manufacturo |

|---|---|---|

|

Quality containment |

Broad containments with lingering doubt |

Precise impact by unit, lot, and operation |

|

Everyday questions |

Manual stitching across screens and exports |

One traceable view from unit to install |

|

Audits and reviews |

One-off pulls and slide decks outside the MES |

Direct answers from governed history |

|

Data and integrations |

Fragile, vendor-gated, hard to extend |

Open, structured, built for internal use |

See what Manufacturo could look like in your environment.

If your MES can’t answer the questions your team asks of it, or feels too loose as you scale, it may be time for a more governed approach.