In today’s aerospace programs, traceability and observability aren’t optional. They’re fundamental to mission assurance, safety, and speed. But the real power comes when these two capabilities work in concert. Aerospace systems are becoming more complex, timelines are tightening, and the cost of uncertainty continues to rise. Engineering teams can no longer afford to treat traceability and observability as separate efforts.

This post outlines how Manufacturo and Sift work together to unify these capabilities-enabling faster development, deeper insight, and the kind of engineering confidence that mission-critical hardware demands.

The Two Tools Working as One

Traceability anchors historical context. Observability powers forward momentum. Together, they form a closed-loop system that accelerates root cause analysis, reduces risk, and strengthens certification workflows.

Traceability provides a verifiable chain of custody for every component, instruction, and environmental factor across the build and integration process. Observability provides a real-time lens into system behavior during test and flight. Sift supports this capability with a complete telemetry infrastructure, including ingestion, storage, and contextual analysis, so teams aren’t just seeing what happened but understanding why it happened in time to act.

According to the 2024 Aerospace Observability Report, 63% of aerospace professionals cite traceability and telemetry management as major challenges due to siloed tools and fragmented workflows. The result? Slower root cause analysis, certification delays, and heightened risk in safety-critical environments.

Manufacturo delivers complete manufacturing and integration traceability. Sift delivers real-time insight into system behavior. Together, they close the loop.

Know Who Built What and When. Down to the Fastener.

True aerospace-grade traceability isn’t just about compliance checkboxes. It’s about enabling confident, high-velocity decision-making across the product lifecycle. From torque specs on a fastener to the technician who performed the installation, traceability builds the foundation for trust.

Manufacturo provides structured, audit-ready records of every step in the production and integration process. When something goes wrong post-flight, engineers can investigate with precision, linking an anomaly to the exact material lot, technician, torque setting, or environmental condition.

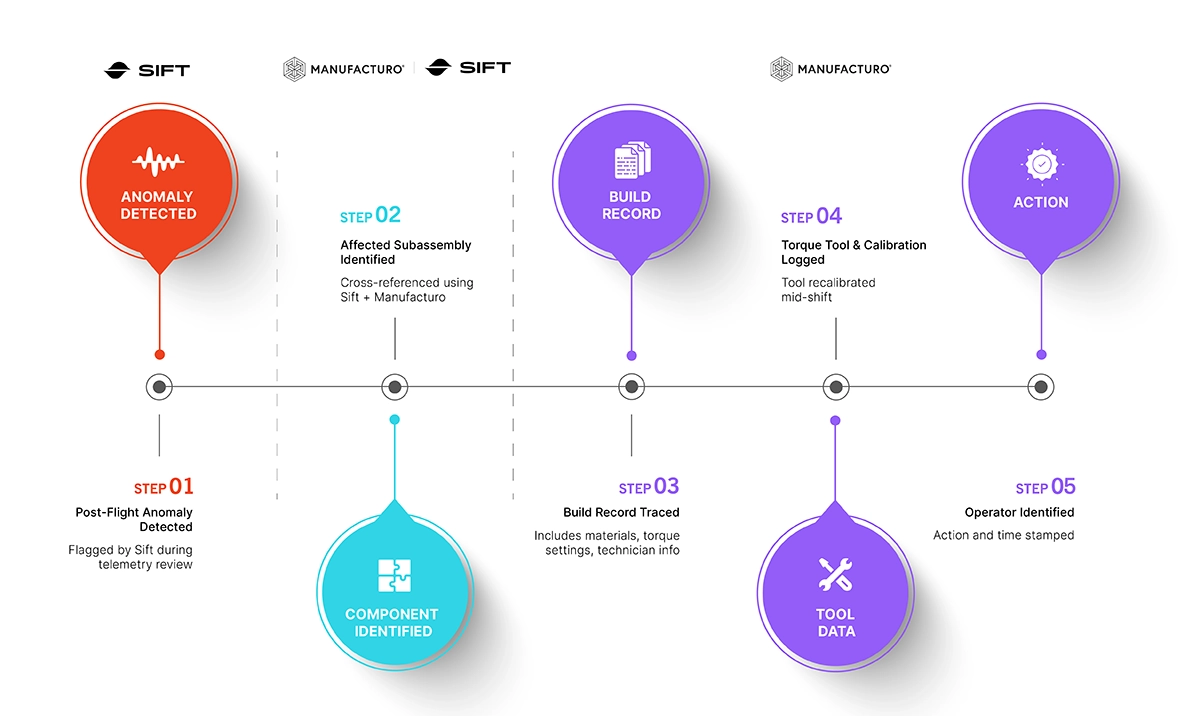

Use Case: Post-Flight Anomaly Root Cause Analysis

Following a propulsion vibration after a test flight, engineers use Manufacturo to trace the affected subassembly to a specific build record. The trace includes technician actions, torque measurements, and tool calibration history. A torque wrench recalibration mid-shift is flagged as the root cause. Because the issue is precisely scoped, the team avoids fleet-wide reinspection and deploys a targeted corrective action.

Stop Reacting to Failures - Start Anticipating Them

Observability isn’t just about alerts. It’s about understanding how complex systems behave in real time, and adapting before small anomalies escalate into major risks.

Sift provides aerospace teams with purpose-built observability infrastructure: scalable ingestion pipelines, schema-aware telemetry normalization, and automated anomaly detection. Engineers can generate derived signals on the fly, annotate anomalies in context, and share findings across test and validation workflows.

Use Case: Flight Test Anomaly Resolution

During a flight test, Sift flags an abnormal thermal signature. Engineers cross-reference the affected component with Manufacturo records and identify it as part of a batch using a new thermal interface material. The root cause? A variance in application thickness. The team updates the SOP, notifies the supplier, and prevents recurrence without disrupting the test campaign.

Trace It. See It. Fix It. Fast.

When traceability and observability are unified, every anomaly becomes a closed-loop learning opportunity. Engineers can see how a system behaved during test, trace that behavior back to the exact configuration that produced it, and act without second-guessing.

This integration turns test data into a strategic asset, streamlining compliance evidence, informing maintenance schedules, and reducing risk across the lifecycle.. Post-flight investigations become faster. Validation becomes more rigorous. Feedback loops become tighter. And confidence increases with every test.

This isn’t integration for its own sake. It’s about minimizing uncertainty and empowering teams to build at the speed of thought.

Unified Evidence. Faster Certs.

This partnership isn’t theoretical. Aerospace teams are already using Sift and Manufacturo together to streamline engineering workflows and compress certification timelines:

- Embed Sift test results directly into Manufacturo workflows, linking test behavior to build records.

- Auto-generate Manufacturo Nonconformance Reports from Sift annotations.

- Sync as-built data from Manufacturo with Sift’s asset model to track components across testing, integration, reconfiguration, and field maintenance—delivering full-lifecycle visibility.

When a hotfire test flags an anomaly:

- Sift generates an annotation and identifies relevant telemetry signals.

- Manufacturo links the test data to a specific unit, operator, and torque setting.

- Engineers trace and validate the fix, all within a single feedback loop.

Engineering Confidence Through Clarity

Traceability and observability each deliver value. But together, they create a new kind of engineering clarity, the kind needed to meet the speed, complexity, and safety requirements of modern aerospace programs.Too often, engineers are building 21st-century machines with 20th-century tools. This partnership replaces fragmented workflows with traceable, real-time clarity—so teams can focus on solving complex problems, not stitching together evidence.

Manufacturo anchors the past. Sift empowers the present. Together, they help aerospace teams build a smarter future.