Introduction

There’s no way of getting around it: manufacturing today is global. Multiple facilities spread across regions. Partners halfway around the world. Language barriers, compliance hurdles, and the constant pressure to move faster.

You want the best partners to build your products, and they may be in another hemisphere. You need a system that supports this, removing boundaries of time, place, and language.

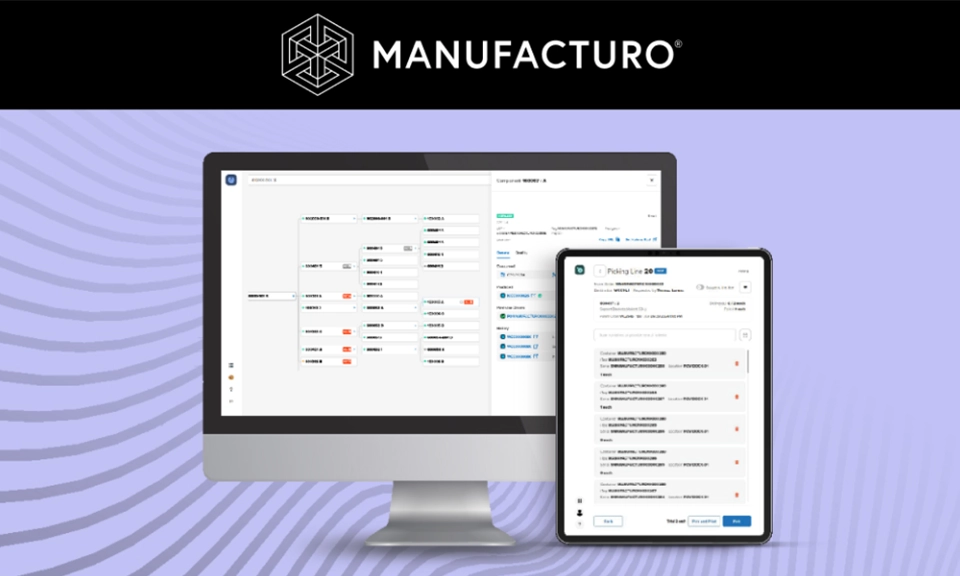

Manufacturo was designed from day one for this modern reality. It's a platform that empowers teams to work as one across languages, sites, and roles.

Built for Multilingual Teams

For cross-national teams, work doesn't happen in one language. Audits, compliance, and reviews often demand English, but your supplier or production team may not work fluently in the world’s lingua franca.

Manufacturo bridges the language gap. Our system is currently operational in English, French, and Japanese, with more language releases happening soon.

Here's why it’s powerful:

- A supplier logs production steps in French or Japanese.

- Their U.S. customer, or international partner, works in the same system with English screens and messages.

- Everyone sees the same data —without duplication, without mismatched formats.

One record. Many languages. Always audit-ready.

Multi-Site Traceability

You likely know this situation: a component is built at one site but tested at another. Or a satellite is assembled across multiple partners and locations before launch.

With Manufacturo, site-specific processes are preserved. Yet, everything rolls up into a single, fully visible and traceable genealogy. Every hand-off is tracked. Every step is visible. Every customer or regulator sees the full chain without gaps.

Two sites. One digital record. Zero blind spots.

Multi-Site Traceability: From Silicon to Sky Without Missing a Beat

The manufacturing world is rapidly evolving toward vertical integration while deepening supply chain partnerships. What used to be simple vendor relationships are now connected ecosystems, which demand visibility across organizational boundaries.

You likely know this cross-regional production environment:

- Raw titanium begins at your Tennessee facility

- Moves to a Michigan partner for precision machining

- Receives a specialized coating at your California supplier

- Completes final integration into a satellite in Florida

Then you also likely know the ensuing challenge:

- Six months after launch, the satellite experiences an anomaly.

- Investigators trace back through dozens of internal and partner facilities, hundreds of components, and thousands of process steps to identify the root cause

- If using a traditional manufacturing and quality management system, there are dangerous gaps at every organizational handoff and rectifying causes is timely and costly, and worse, not always accurate.

What you get instead with Manufacturo:

- Every process is captured, internal or external

- Activities roll into a single, traceable genealogy

- Root cause identification and rectification is simple, straightforward, accurate, and timely

Example: Michigan heat treatment data (temperature curve, operator cert) links directly to Tennessee material certs and California coating parameters – all before Florida integration

The result: Every handoff is tracked across organizational boundaries. Every step retains local context while feeding the global record. All customers or regulators see the entire chain without gaps - from your vertically integrated operations through strategic partners to final testing.

Permissions that Scale with Compliance

A principle in building our platform is balancing agility with control. Complex manufacturers need a system that gives them flexibility, molding to their processes, while also proving the structure for stability and security.

That’s exactly what Manufacturo’s permission model does: define a role once, apply it across sites, and keep visibility where it belongs. That way collaboration is streamlined with:

- Operators seeing their local work.

- Program managers see the global chain.

- Sensitive records remain secure for compliance with ITAR, ISO, and beyond.

See what you need. Protect what you must.

Time Knows No Boundaries: Global Operations in Your Local Time

A principle in building our platform is making global coordination feel effortlessly local. Complex manufacturers operate across continents, but their teams shouldn't need to do mental math every time they check when a critical process started in Shanghai or when a delivery arrives in São Paulo.

That's precisely what Manufacturo's intelligent time zone system does: capture events in their local context, display them in yours, and maintain global synchronization without confusion. That way, operations flow seamlessly with:

- Shop floor operators seeing their work in local time

- Global program managers tracking worldwide milestones in their time zone

- Critical timestamps maintaining accuracy for compliance and audit trails

When your Munich facility reports a quality issue at 14:30 CET, your Los Angeles team sees it as 5:30 AM PST—no conversion required, no missed context, the system automatically handles daylight saving transitions, international date lines, and regional calendar differences.

Think globally. See locally. Act precisely.

Conclusion

Manufacturing today is without borders, and your platform needs to break down barriers between teams, not build them up.

From aerospace suppliers to satellite builders to new energy innovators, forward-thinking companies choose Manufacturo because it was built for their world: multilingual, multi-site, and compliance-ready from day one.

One platform. Many sites. Every language. Always connected.