We chose Manufacturo because it offered us the chance to be part of the development process, guiding and customizing the tool while using a fresh, adaptable system tailored to our needs.

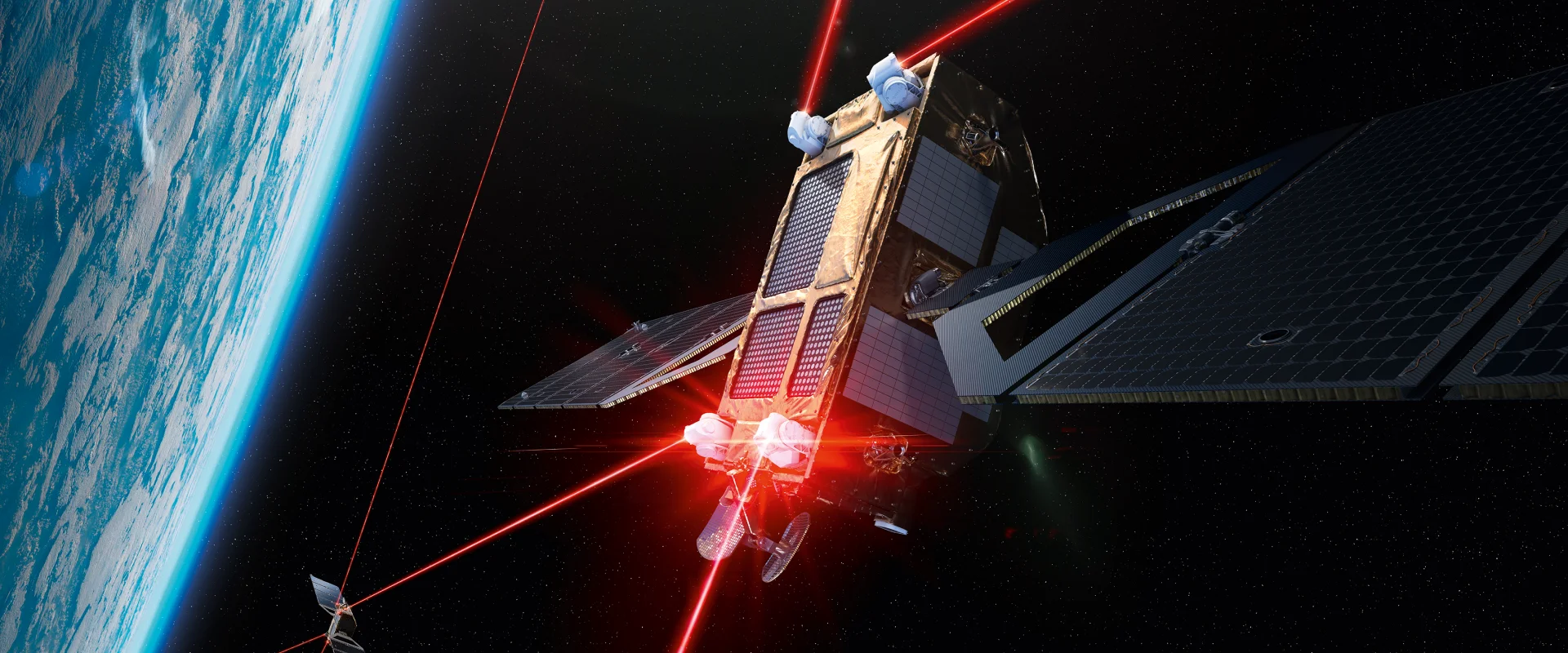

How Manufacturo Is Powering Mynaric's Industrial Revolution of Optical Communications

While laser communications technology has been around for decades, Mynaric is focused on bringing affordable, scalable and industrialized laser communications products and technology to the industry. The key to scalability to meet the growing demands of the market is serial production. In order to manufacture products at scale, Mynaric teamed up with Manufacturo, a SaaS provider of a cloud-based manufacturing execution system (MES) for complex manufacturing industries.

Aided by Manufacturo's innovative solutions, Mynaric was able to:

Achieve an Accelerated Receiving Process

Orders that once took up to a month to process were reduced to just three days after optimizing workflows, with goals set to further bring this down to a single day.

Transition to Digital Documentation

Mynaric swapped their paper-based methods for a digital process, significantly minimizing human errors.

Streamline Auditing

The audit process was simplified considerably, bolstering Mynaric's credibility with major customers and suppliers and facilitating smoother operations.

Introducing Mynaric-The Vanguard of Laser Communications

Emerging from the renowned German Aerospace Center (DLR), Mynaric is focused on leading the industrial revolution of laser communications by producing optical communications terminals for space, airborne and mobile/terrestrial applications. Laser communication networks provide connectivity from the sky, allowing for ultra-high data rates and secure, long-distance data transmission between moving objects for wireless terrestrial, mobility, airborne, and space-based applications. This robust foundation set the stage for their alliance with Manufacturo-an alignment of two titans ready to drive innovation and excellence.

From Start-Up to Scale-Up: Embracing Advanced Solutions

Mynaric prioritizes scalability as the key to enabling global connectivity. As the company rapidly grew, it became increasingly important to have operations that were transparent, flexible, and easy to audit, especially given their work with major defense contractors. They weren't just in search of software; they were looking for a way to enhance their operations and a partner aligned with their goal of mass-producing highly technical and effective products.

Manufacturo emerged as that partner. Known for their knack in simplifying processes and their top-tier MES, it became clear that the two companies had a shared vision. As Peter Dachs, Head of Production and Test at Mynaric, mentioned,

"Manufacturo's system simplified our work while meeting all audit needs. We had two main goals: optimize our processes and increase our production rate."

The collaboration between Mynaric and Manufacturo proved fruitful. They swiftly integrated Manufacturo's production and logistics system at Mynaric’s primary facility in Gilching, Germany. Encouraged by this success, Mynaric soon introduced the system at their Hawthorne California, location, marking a step forward in their journey to consistent, transparent operations across their facilities

Unified Process View Bolsters End-to-End Traceability

Unified Process View Bolsters End-to-End Traceability In the aerospace sector, traceability is paramount for safety and compliance. Manufacturo's seamless integration empowered Mynaric to create intuitive, customized process plans, enhancing end-to-end traceability.

Aviva Buller, Vice President of Global Supply Chain at Mynaric, spoke on the efficiency of Manufacturo’s One View Genealogy application. "The one view aspect, where you can hit a button and see where all the lot goes, trace all the parts issued into that work order-that's huge," she acknowledged.

Building on Buller's praise, Mynaric's Head of Production and Test Peter Dachs lauded the platform's transformative impact on their traceability.

"With Manufacturo, we've experienced enhanced tracking of nonconforming parts and benefitted from robust data capturing capabilities. We've transitioned from relying heavily on Excel sheets and PDFs for specific processes, moving towards an integrated system,"

Dachs stated, emphasizing the significant evolution of their operations.

Enhanced Nonconformance Management Drives Efficient Production

Enhanced Nonconformance Management Drives Efficient Production Mynaric's commitment to serial production prioritized transparency and efficiency. This led them to adopt Manufacturo's Nonconformance Management application, moving away from their previous Jira-based solutions. This new platform integrates smoothly with production and logistics processes, making data input more efficient and decision-making more informed.

The introduction of Nonconformance Management has been transformative. By spotlighting potential issues earlier in the production process, costly errors have been significantly reduced. Mynaric's VP of Global Supply Chain Aviva Buller sheds light on its impact: "Before, production could be delayed because of a single part's nonconformance. With Manufacturo, we now have the ability to assign unique identifiers to parts. Conforming components can continue their workflow, while any nonconforming part is immediately identified and addressed. This streamlined approach has been instrumental in expediting our production process."

While Manufacturo has facilitated significant advancements, Mynaric continues to refine certain processes. Ongoing evaluations, such as the optimization of incoming inspections, showcase their commitment to continuous improvement and innovation.

Aviva Buller further expressed appreciation for the new system's flexibility:

"One of the standout features is our ability to adjust trace profiles swiftly. This isn't just about fixing data inaccuracies, but adapting to evolving requirements for parts. It's a testament to the system's adaptability and our move towards a digital-first approach."

Enhancing Warehouse Management: From Weeks to Days

As Mynaric expanded, streamlined warehouse management became critical. The previous system, began to reveal its limitations in the face of Mynaric's rapid growth. Manufacturo's integrated inventory module revolutionized product traceability and operational efficiency.

The distinction of Manufacturo lay in its unparalleled transparency. As Mynaric's horizons broadened, the upgraded system effectively refined audit procedures and the receiving process. Every product, without exception, became easily traceable throughout its journey.

With Manufacturo's backend data accessibility and enhanced location management features, receiving timelines saw a significant reduction. Previoulsy, nuances of the system sometimes caused backlogs, elongating receiving durations. Through various improvements and optimizations, and especially with the addition of Manufacturo's systematic methodology, receiving times were cut down impressively to just three days. With continued advancements, Mynaric is poised to further optimize, setting an ambitious goal to bring it down to a single day.

Unlock manufacturing excellence with Manufacturo

Building a Future Together

"One key reason we chose Manufacturo is its capability to function in multiple time zones. Having team members in two time zones, who could swiftly address any issues, was vital,"

said Peter Dachs, Head of Production and Test at Mynaric.

James Montgomery, Chief Product Officer at Manufacturo, stated,

"Working with Mynaric has provided us an exciting opportunity to engage with a transformative industry. We thrive on the challenge of working with startups and hi-tech businesses to help streamline and scale their operations. Together with Mynaric, we have developed new functionalities in Manufacturo to better support their business while closely collaborating with their team during the introduction of a new ERP solution."

Echoing a similar sentiment, Dachs mentioned, "We chose Manufacturo because it offered us the chance to be part of the development process, guiding and customizing the tool while using a fresh, adaptable system tailored to our needs."

As the partnership between Mynaric and Manufacturo evolves, both companies remain focused on innovation and setting industry benchmarks, symbolizing a combined vision for the future of industralized laser communications and digital transformation.