Manufacturo Partners with Karman Industries to Scale Manufacturing for High-Efficiency Thermal Systems

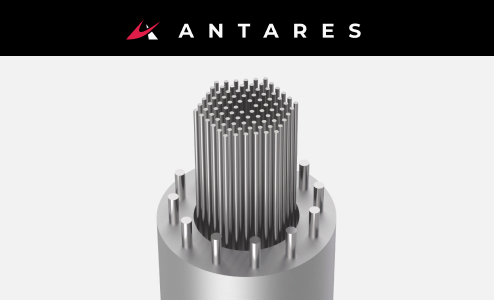

Manufacturo, a next-generation manufacturing software platform for high-complexity production, has partnered with Karman Industries, a Los Angeles-based thermal technology company. The collaboratio...