Executive/C-Level

C-level executives gain the single source of truth of all three manufacturing areas, i.e., production, quality, and supply chain, to ensure informed strategic decision-making and organizational transparency. Manufacturo enables executives to effortlessly track the high-level status of specific programs, identifying problem areas promptly and understanding what actions are needed. By pinpointing bottlenecks and inefficiencies, executives can strategize on how to accelerate processes and optimize resource allocation, ultimately saving both time and money. With clear visibility into operations, they can swiftly identify accountability for issues and access fast business metrics, enabling agile responses to evolving situations. Additionally, tracking progress against deadlines and understanding the cost implications in real time helps executives make informed decisions to ensure projects stay on track and within budget, while also exploring ways to save costs and drive overall efficiency.

Manufacturing/Production

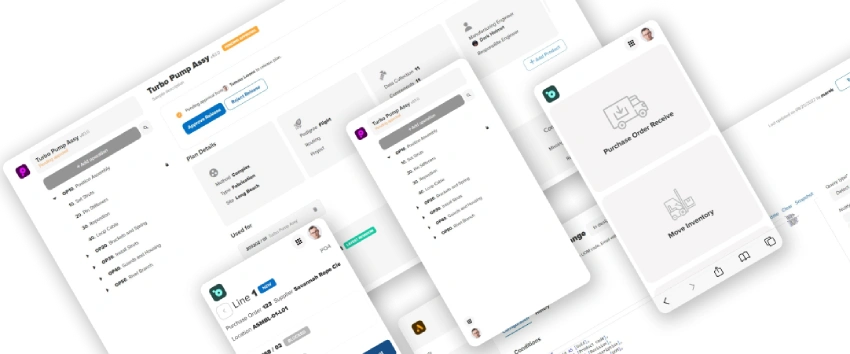

Technicians, supervisors, and production managers can perform their tasks faster and more efficiently. Technicians can quickly and effectively follow clear and intuitive work instructions, without the need to fill out too many details. Supervisors and production managers are able to quickly get the status of the in-progress products they need to build. Consequently, it’s much easier for supervisors to manage the capacity of their technicians and equipment, knowing they have all materials and equipment ready in advance to get the job done.

Engineering

Manufacturing, test, and integration engineers can efficiently minimize constraints, easily track as-built configuration, and effectively manage process controls to constantly communicate with various stakeholders to make sure the design intent is always met with the shop-floor operators, production coordinators, quality, and procurement.

Quality

Quality specialists can contain and correct errors inline in real time to prevent defects from escaping across assembly lines downstream, providing engineers with crucial data and insights that enable calculated dispositions and instant adjustments of work instructions inline to fix errors.

Supply Chain/Inventory

Supply chain and inventory managers can successfully enforce consistent standards across fragmented manufacturing processes through centralized tracking of all inventory movements and material quantities in real time to prevent manufacturing inefficiencies and eliminate unexpected component shortages.

IT

IT staff has a lower bill of IT, freeing IT specialists from having to manage additional servers, software, security, patching, or databases, allowing them to shift focus towards maintaining the existing on-site infrastructure and systems.