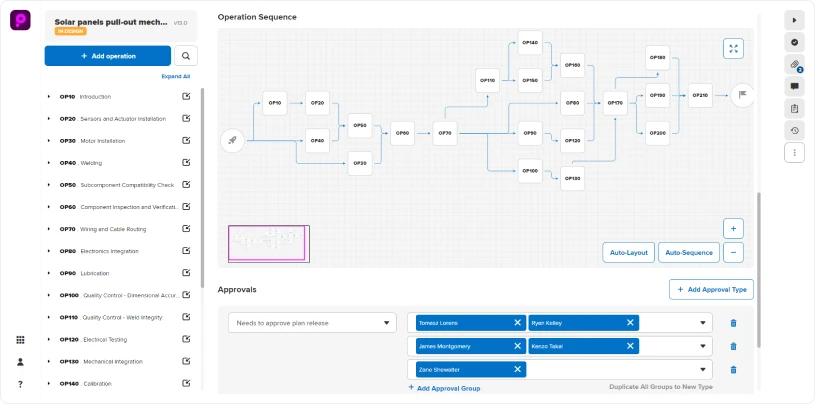

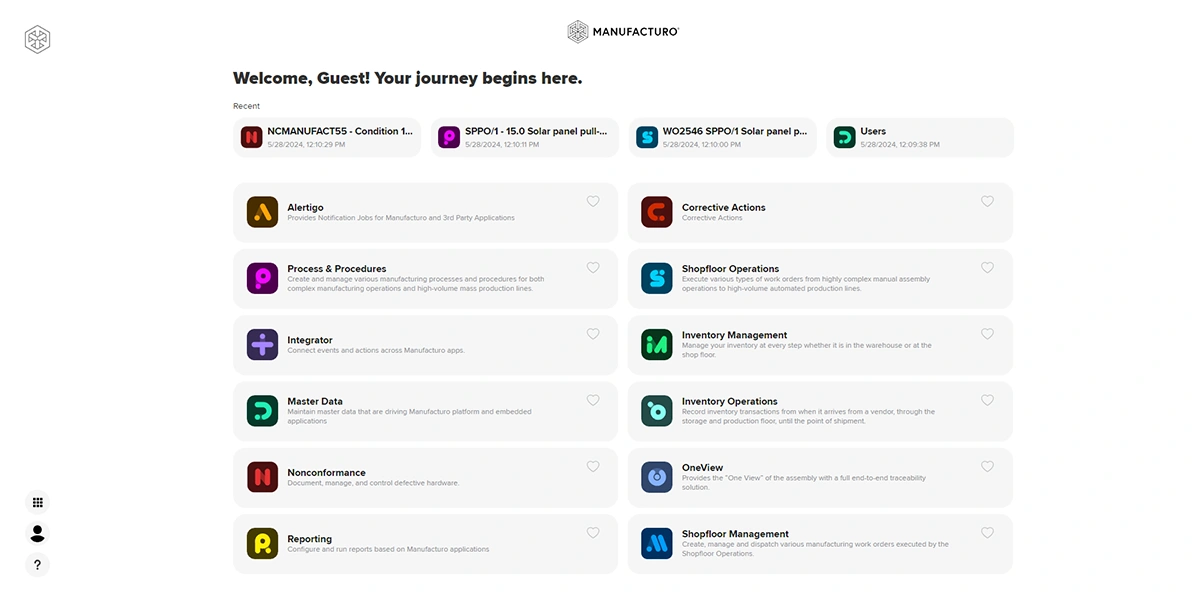

Production

Production management encompasses the procedures that determine how complex products can efficiently flow through the assembly, integration, and testing lifecycle, while also syncing with design. The data collection engine captures critical product information available for near real-time analysis, facilitating well-informed decision making and more profitable outcomes.

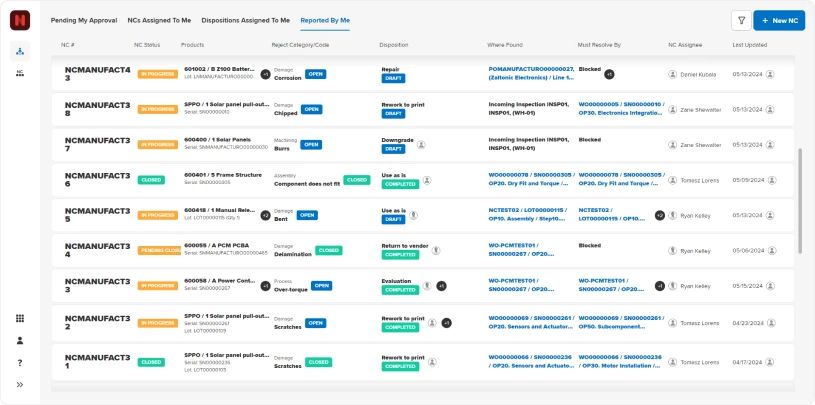

Quality

Embedded quality management—featuring improved QA processes--yields precision operations that feature greater efficiency and cost savings, strengthened compliance and risk mitigation, and enhanced brand reputation.

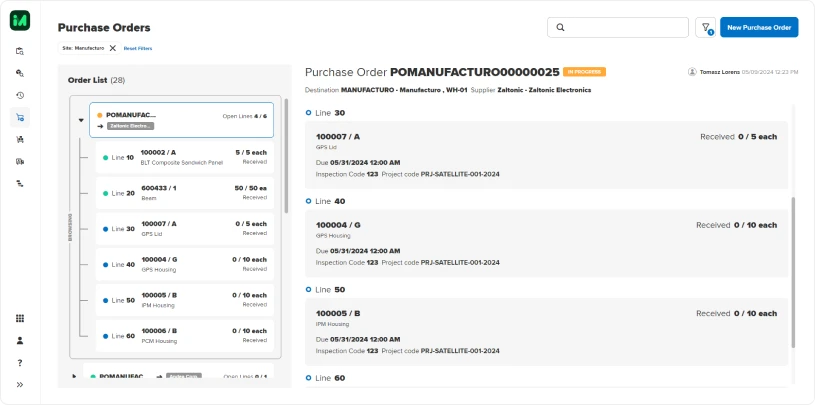

Supply chain

Supply chain management (SCM) software establishes the foundation for a steady and reliable flow of high-quality materials and components, from procurement to product delivery.