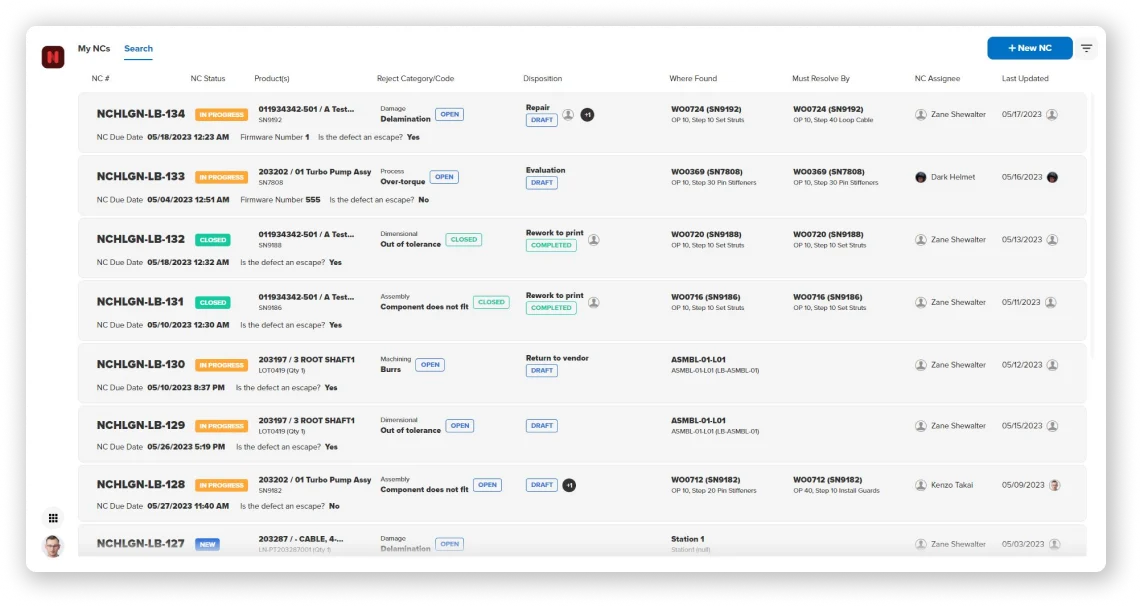

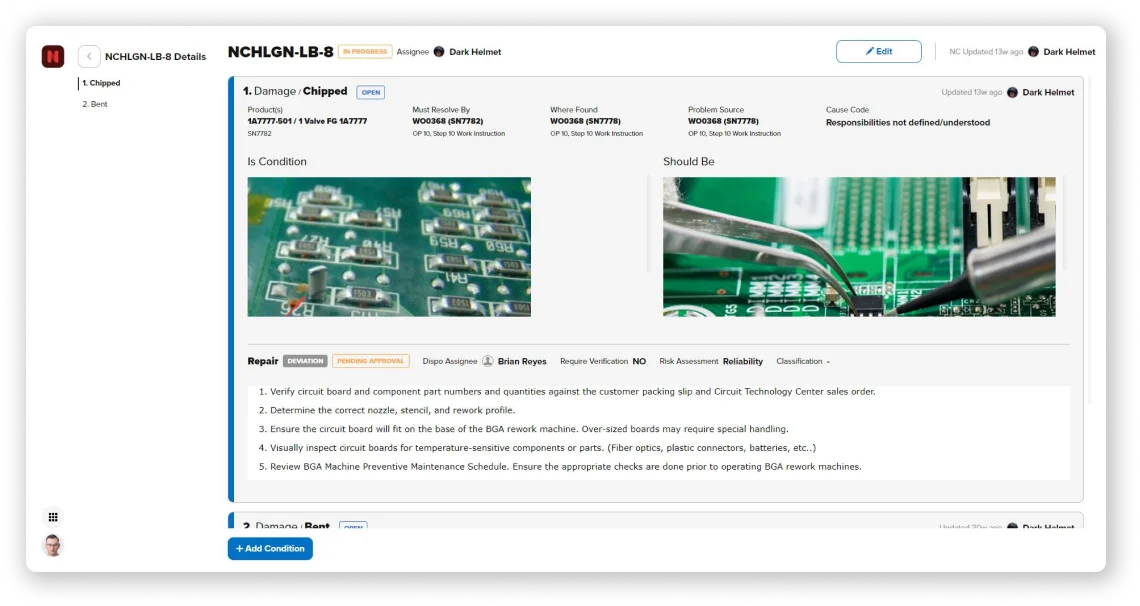

To find out more about other manufacturing execution capabilities, visit manufacturing management software. The following are details on Nonconformance Management that enables companies to effectively control and monitor the nonconformance process and improve quality management at every stage.