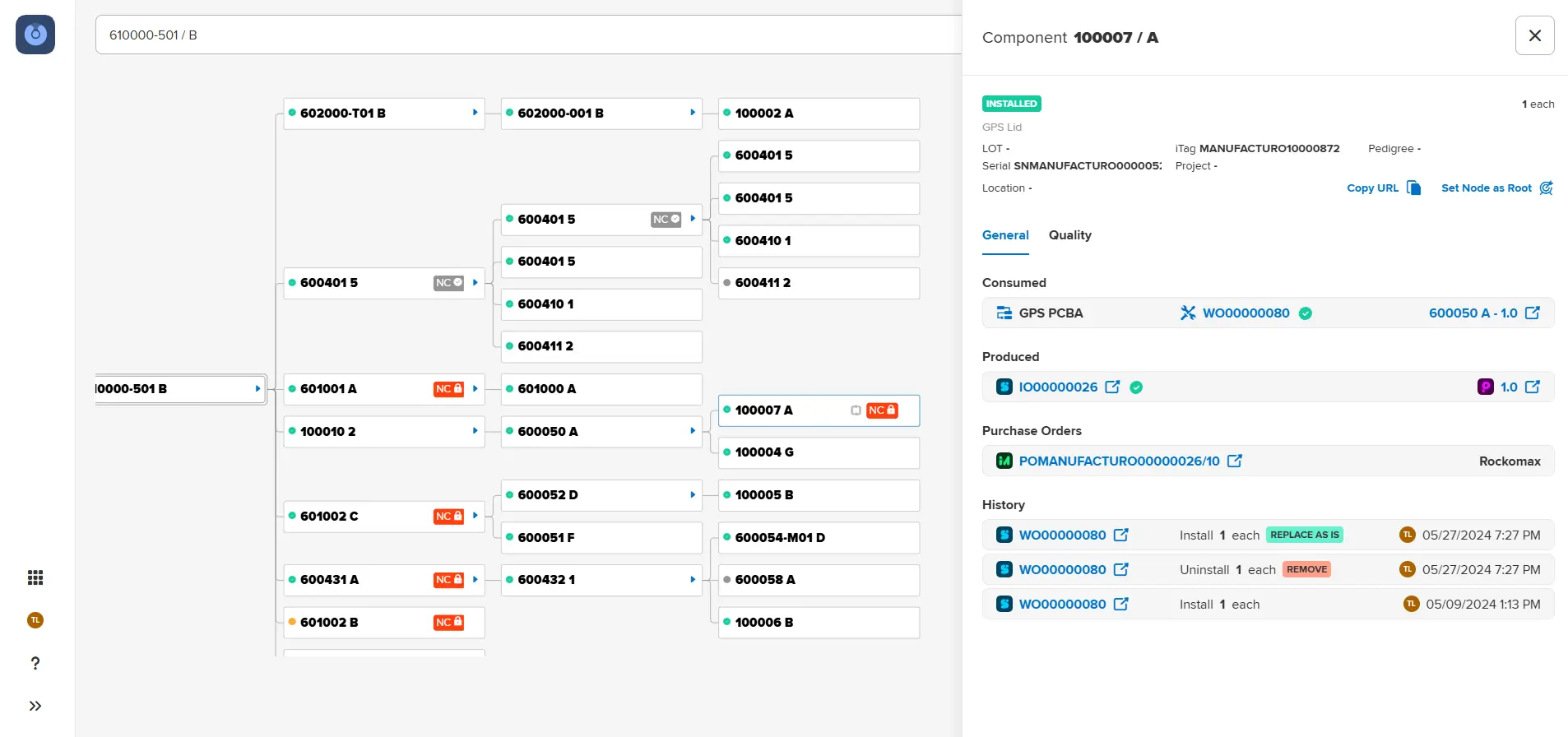

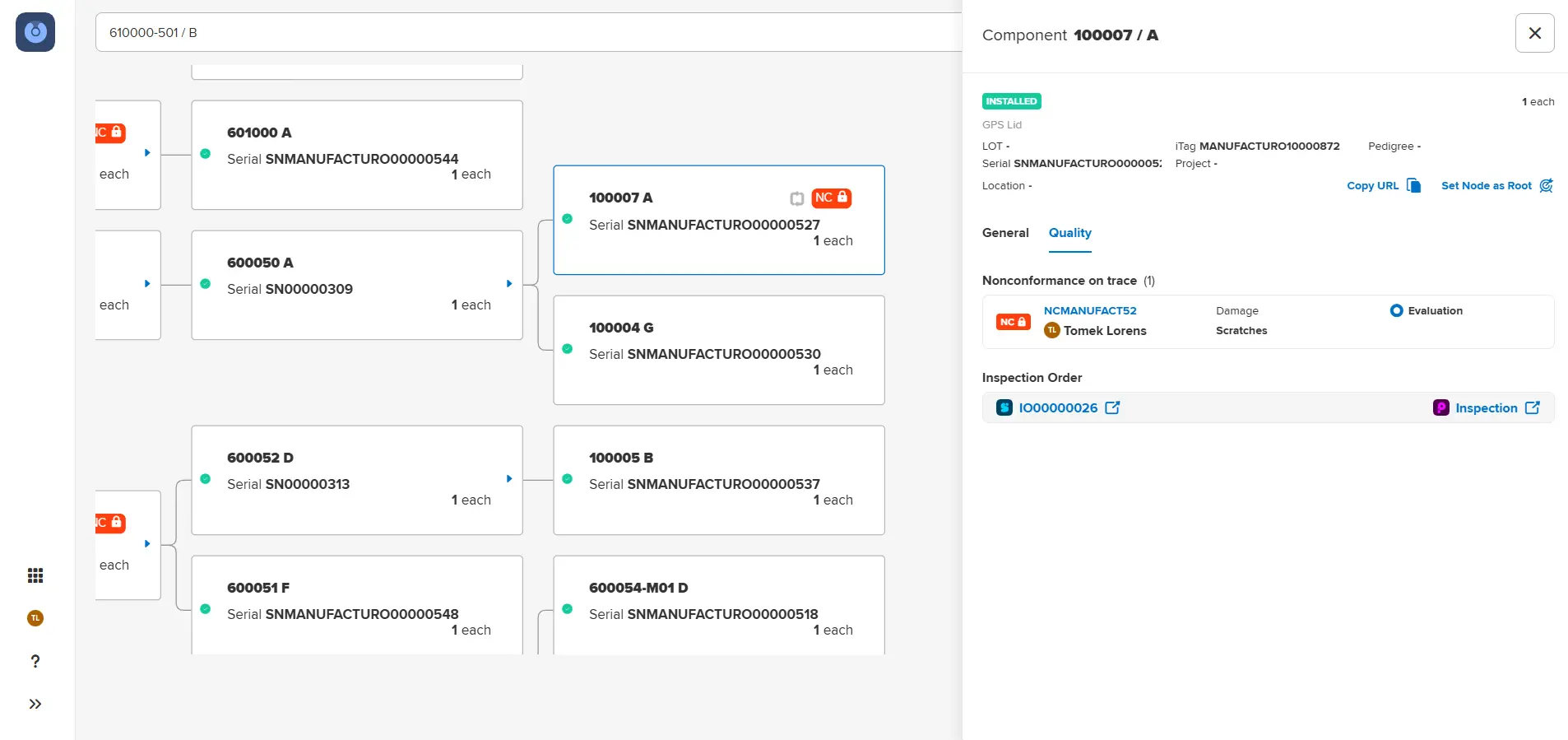

To facilitate robust manufacturing traceability from the planning phase, through shop-floor operations, all the way to as-built reports, Manufacturo MES software provides a set of out-of-the-box applications that enhance product control and eliminate quality issues.

To learn more about production process management solutions, visit Manufacturo MES software. The following are details on One View Genealogy that helps manufacturing engineers and shop-floor operators achieve complete traceability of all components and parts at every stage of manufacturing operations.