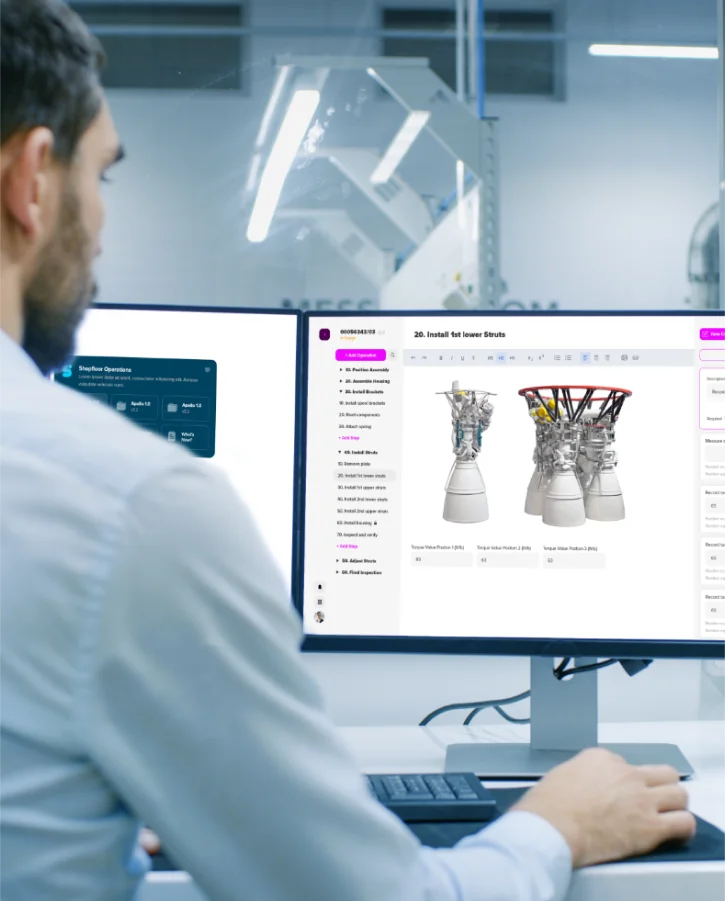

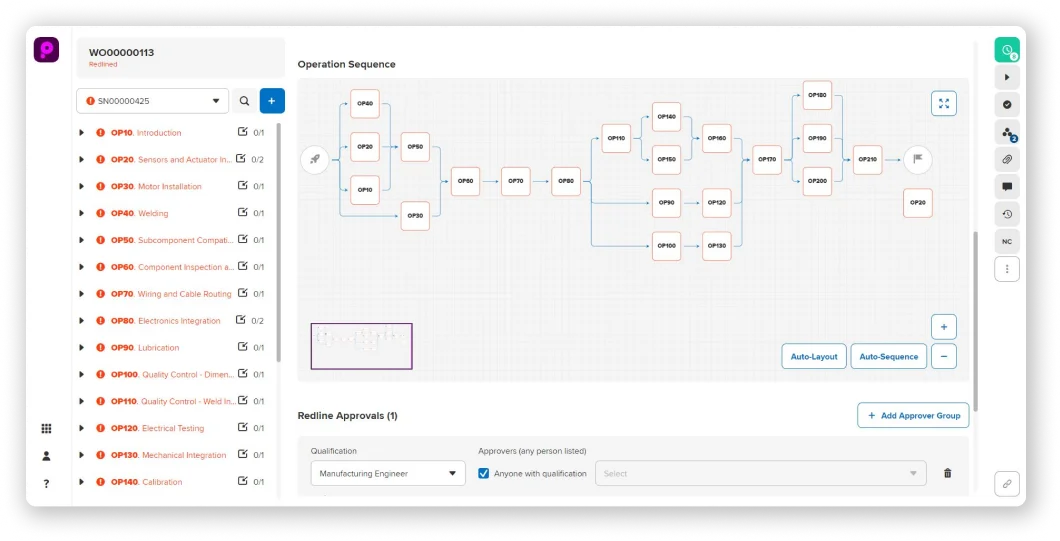

Our manufacturing software solution offers highly specialized manufacturing planning tools to effectively facilitate production management.

To learn more about each unique application and production process, visit manufacturing management software. The following are details on Process Planning that allows for developing a detailed production plan.