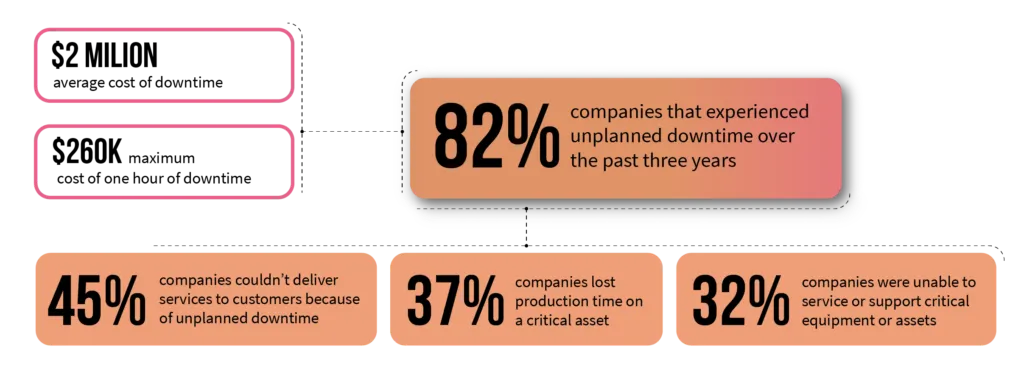

Consumers today demand goods and services on time and to spec. The biggest players in every industry have set a tremendous bar that competitors must match, and one thing every market leader has in common is that they strive to get the most out of their resources by reducing machine downtime. A recent study by ServiceMax found that:

- 82% of companies have been impacted by at least one unplanned outage involving their machinery/assets over the past three years

- Achieving zero unplanned downtime is the number one priority for the board at 20% of organizations, and a high priority for 50%.

- 70% of companies are now aware of when equipment assets are due for upgrade or maintenance

The cost of downtime is staggeringly high – up to $260,000 per hour

Downtime by the numbers

Not all downtime is created equal, and not all downtime is a negative phenomenon. It’s necessary to differentiate, for example, between planned and unplanned downtime:

- Planned downtime is time specifically scheduled to address equipment performance, facility maintenance, tool breaks, inspections, hardware/software upgrades, facility maintenance, and other necessary tasks. Because planned downtime is anticipated, the time and money invested (as well as the productivity and labor losses) can be controlled.

- Unplanned downtime is any unforeseen event that reduces the return on investment by causing disruptions in quality, cost, and cycle time. It’s typically thought of in terms of equipment failure due to poor maintenance, but human error and slow changeovers can also contribute to lost time and revenue.

When it comes to unplanned downtime, just being able to accurately calculate your downtime correctly can give you an advantage over your competition. The data suggests that 80% of industrial plants are unable to estimate downtime accurately. And the ones that can often under-calculate the downtimes by up to 300%.

While that may seem surprising, the 80% figure begins to make sense when you consider the difficulties of accurately calculating unplanned downtime. Doing so requires a heightened awareness of multiple aspects of your business, specifically:

- The hours of operation of the machine or machines in question

- The hours of downtime

- The average total number of units produced per week by each machine

- The gross profit per unit

Even having these numbers available and being able to plug them into an equation won’t tell you everything – your lost profit is just the tip of the iceberg. Chances are that fixing the issue that has brought a machine to a halt will require paying a specialist, and your true losses will always be driven by labor costs – idle workers still need to be paid, after all.

If you’re not yet convinced of the seriousness of unplanned downtime, here are some more statistics to consider:

Keeping downtime under control

There’s an adage that states, “An ounce of prevention is worth a pound of cure.” It’s never been truer than when it comes to minimizing the impact of unexpected downtime. The most effective way to prevent your valuable assets from malfunctioning or failing at the worst possible time is to develop what’s known as a preventive maintenance strategy. Preventive maintenance is a proactive maintenance strategy that involves regular and routine maintenance of equipment to reduce the likelihood of failure (and therefore the likelihood of unplanned downtime).

The basic principle is one of performing maintenance on critical machinery while it is still operational instead of waiting for problems to develop. Just as going to the dentist for a routine checkup every few months keeps you from having to replace your teeth, a preventive approach to equipment and machinery maintenance increases availability and operational output of through regularly scheduled cleaning, repairs, adjustments, and part replacements. It’s an approach that pays for itself and then some – running an asset to the point of failure can cost a business up to 10 times more in repairs and lost production.

There are 5 steps involved in setting a preventive maintenance schedule:

- Define the potential problem

- Measure current asset performance to establish a baseline

- Identify and explore possible causes of the problem

- Analyze the best approach

- Calculate how well your current approach has been working and adjust as needed

Fortunately for manufacturers, modern technology is on your side every step of the way, particularly the latest developments in the field of cloud-based, SaaS Enterprise Asset Management (EAM).

Historically, while the EAM software offered a comprehensive set of preventive maintenance modules, it lacked the ability to track and utilize the shop floor data. However, what one would call a design flaw, the other sees as an opportunity to create a solution that not only encompasses EAM’s standard set of maintenance capabilities but also addresses the flaw by adding the capability to handle low-level PLC or SCADA data.

As the IoT continues to transform the industry, such solutions have already been designed, including our SaaS manufacturing platform, Manufacturo. Manufacturers are no longer forced to choose and compromise between costly MES deployments, somewhat limited capabilities of EAM, or even more niche solutions like CMMS (Computerized Maintenance Management System), to improve and extend asset quality and reliability. Another advantage of modern, cloud-based EAM software is the all-around access to a shared asset registry that allows broader standardization of asset definitions and decreased manual data input.

Furthermore, the SaaS and cloud-based model removes the need for constant IT involvement as upgrades or system maintenance are performed remotely by the service provider. With the latest developments in preventive maintenance software, manufacturers can truly focus on preventing, not putting out fires, and fully utilize the usable life of their assets to reduce unplanned downtime.